Symmetrical straight beam structure condenser type micro-acceleration sensor and manufacturing method thereof

A technology of acceleration sensor and structural capacitance, which is used in the measurement of acceleration, velocity/acceleration/shock measurement, instruments, etc., can solve the problem of not being able to significantly reduce the cross-axis sensitivity and large lateral sensitivity of the device, so as to reduce the cross-sensitivity and simplify the process. , the effect of balancing thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

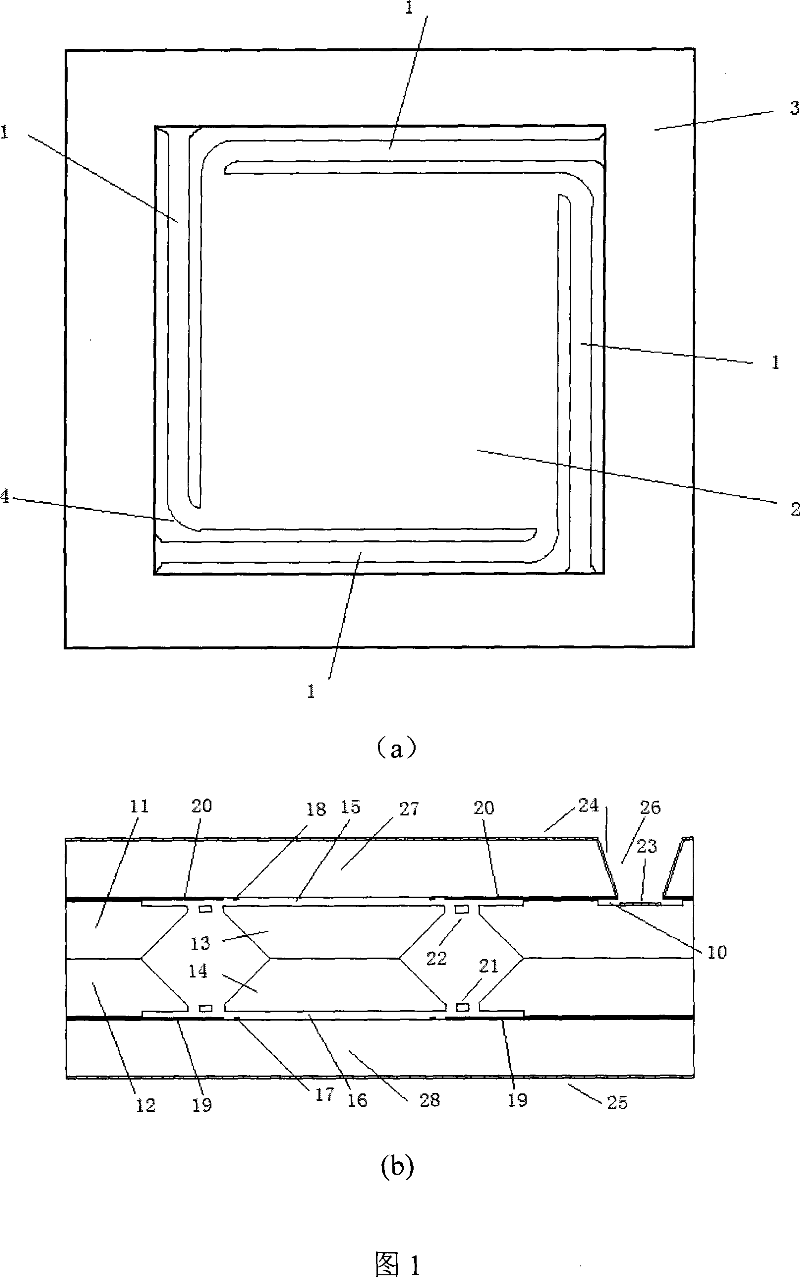

[0044] Embodiment 1 of the present invention relates to a structure of a micro-acceleration sensor, which is described in conjunction with FIG. 1 .

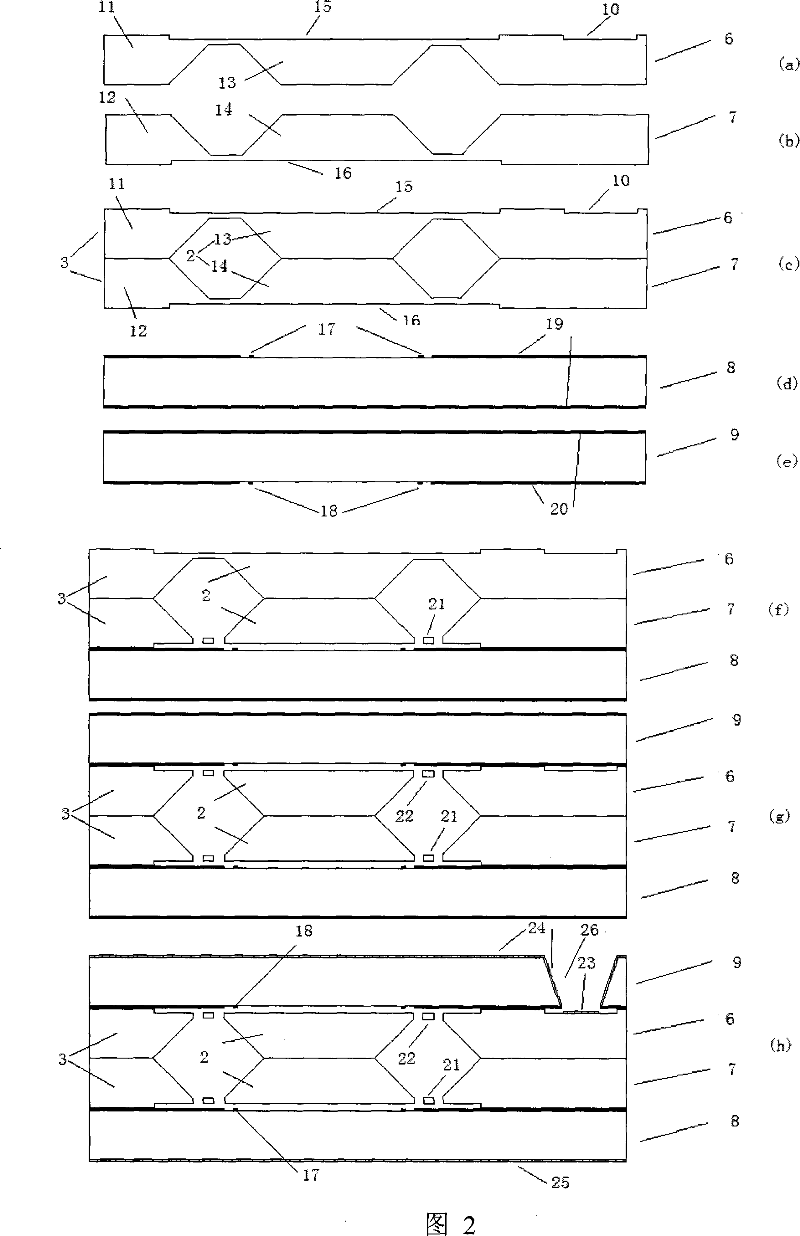

[0045] As shown in Figure 1(a), one end of the straight elastic beam 1 is connected to the top corner of the central mass 2 through a short beam 4, and the other end is connected to the external support frame 3 perpendicular to it. As shown in Figure 1(b), the micro-acceleration sensor structure includes a centrally symmetrical mass block 2, an external support frame 3, and eight vertically symmetrical straight elastic beams connected to the centrally symmetrical mass block 2 and the external support frame 3 1 and upper cover plate 27, lower cover plate 28. The mass block 2 is composed of the top mass block silicon chip 6 and the bottom mass block silicon chip 7, the straight elastic beam structure 1 is composed of the top elastic beam 22 and the bottom elastic beam 21, and the external support frame 3 is composed of the top supp...

Embodiment 2

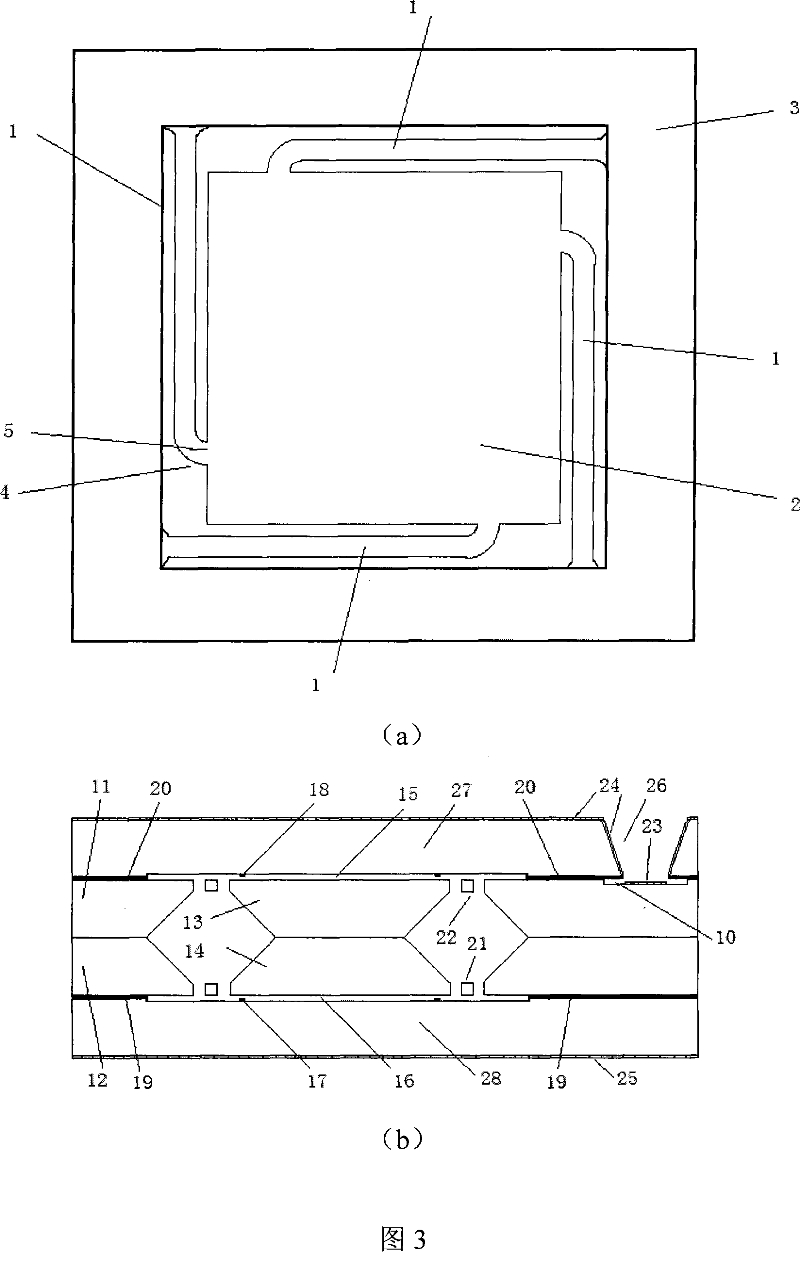

[0057] Embodiment 2 of the present invention relates to another micro-acceleration sensor structure, which differs from Embodiment 1 in that the distribution of the straight elastic beams and the position of the capacitance gap are different.

[0058] As shown in Fig. 3(a), one end of the straight elastic beam 1 is connected to any position 5 along the side length of the central mass 2 except the top corner through the short beam 4, and the other end is connected to the external support frame 3 perpendicular to it. As shown in Figure 3(b), the micro-acceleration sensor structure includes a centrally symmetrical mass block 2, an external support frame 3, eight up-and-down symmetrical straight elastic beam structures 1 connected between the mass block 2 and the external support frame 3, and the upper and lower Cover plate 27, lower cover plate 28. The centrosymmetric mass block 2 is composed of the top mass block silicon chip 6 and the bottom mass block silicon chip 7, the strai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com