High acceleration temperature changing test chamber

A test box, high-acceleration technology, applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve the problem of difficult control of the air flow in the box, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

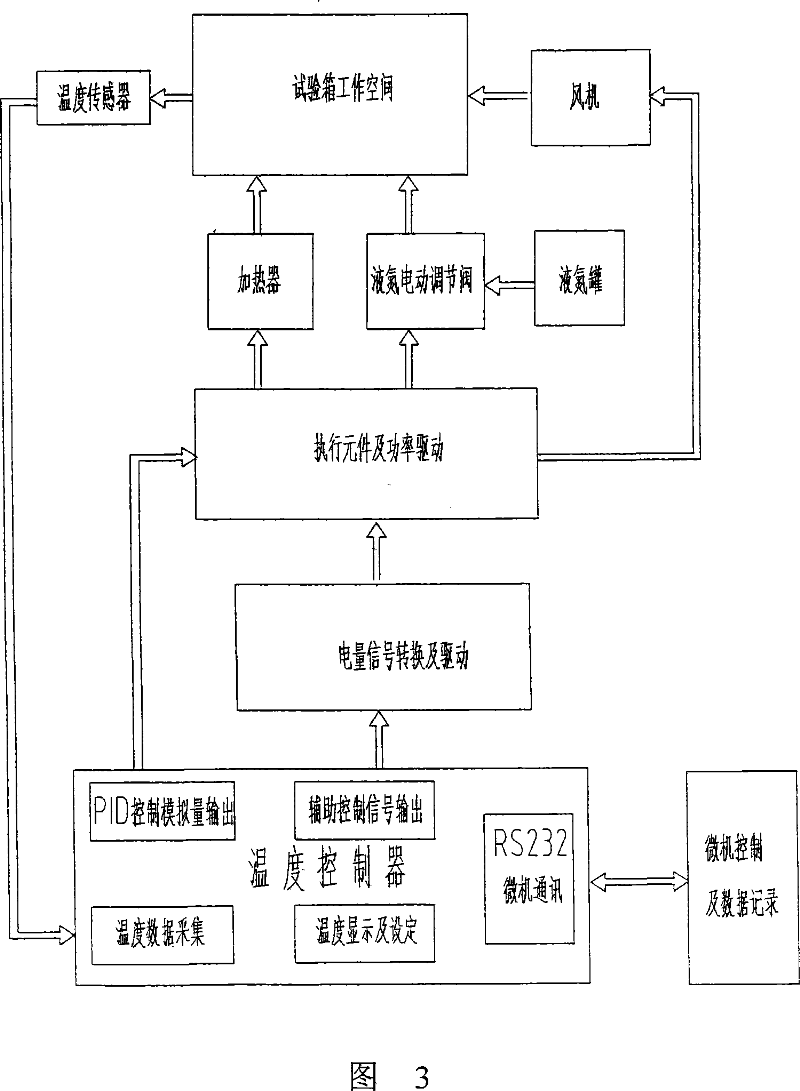

[0015] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

[0016] The present invention mainly consists of a motor 1, a nozzle 2, an axial fan blade 3, a pressure balance hole 4, a rear cover 5, an outer shell 6, an insulation layer 7, an inner tank 8, an air flow in the box 9, a channel steel bracket 10, and an air suction port Plate 11, air outlet plate 12, working room 13, upper cavity A of the box body, lower cavity B of the box body, air outlet 14, electrical control box 15, outer layer sealing strip 16, door sealing strip 17, FRP connection frame 18 , inner sealing strip 19, baffle plate 20, bracket 21, stainless steel nickel-chromium wire ceramic bracket heater 22, lighting lamp 23, high and low temperature resistant hollow glass with conductive film 24, door 25, liquid nitrogen storage tank 26, pressure regulating valve 27 , pipeline 28, solenoid valve 29 and other components.

[0017] As shown in Fig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com