Catalyzer for producing difluoromethane by vapor-phase fluorination and the preparing method

A fluorination catalyst, difluoromethane technology, applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of small specific surface area, catalyst deactivation, poor activity, etc., and achieve high activity , The operation method is simple, the effect of fast price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

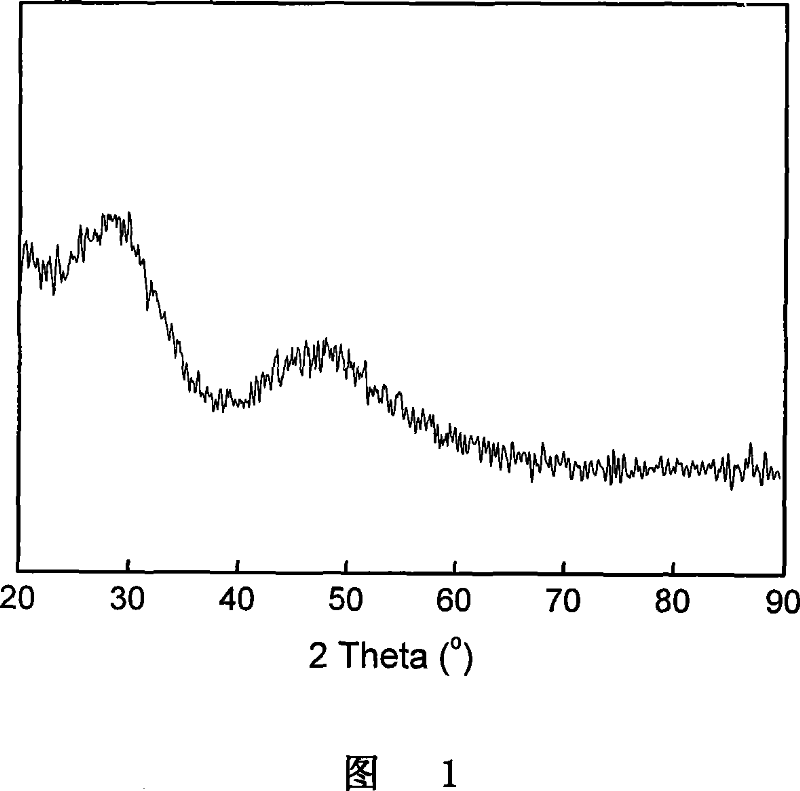

Image

Examples

Embodiment 1

[0019] First, weigh CrCl according to the loading of Cr as 10wt%. 3 9H 2 O and Y (NO 3 ) 3 ·6H 2 O, after dissolving with an appropriate amount of water, mix well, add a certain amount (NH 4 ) 2 CO 3 , adjust the pH value of the solution to 8 to make the two precipitate completely, then centrifuge, wash until the filtrate is neutral, and then dry at 120°C for 12 hours; then press into tablets, and then bake at 400°C for 4 hours to obtain Fluorination catalyst precursors. The fluorination catalyst precursor was dried under normal pressure with nitrogen gas at 300°C for 10 hours, and then treated with anhydrous HF at 400°C for 10 hours to obtain a fluorination catalyst. Its reactivity and selectivity are listed in Table 1.

Embodiment 2

[0021] First, weigh Cr(NO 3 ) 3 9H 2 O and Y (NO 3 ) 3 ·6H 2 O, after dissolving with an appropriate amount of water, mix well, add a certain amount (NH 4 ) 2 CO 3 , adjust the pH value of the solution to 8 to make the two precipitate completely, then centrifuge, wash until the filtrate is neutral, and then dry at 120°C for 12 hours; then press into tablets, and then bake at 400°C for 4 hours to obtain Fluorination catalyst precursors. The fluorination catalyst precursor was dried under normal pressure with nitrogen gas at 300°C for 10 hours, and then treated with anhydrous HF at 400°C for 10 hours to obtain a fluorination catalyst. Its reactivity and selectivity are listed in Table 1.

Embodiment 3

[0023] First, weigh Cr(NO 3 ) 3 9H 2 O and YCl 3 ·7H 2 O, after dissolving with an appropriate amount of water, mix well, add a certain amount (NH 4 ) 2 CO 3 , adjust the pH value of the solution to 8 to make the two precipitate completely, then centrifuge, wash until the filtrate is neutral, and then dry at 120°C for 12 hours; then press into tablets, and then bake at 400°C for 4 hours to obtain Fluorination catalyst precursors. The fluorination catalyst precursor was dried under normal pressure with nitrogen gas at 300°C for 10 hours, and then treated with anhydrous HF at 400°C for 10 hours to obtain a fluorination catalyst. Its reactivity and selectivity are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com