One-way valve

A one-way valve and valve body technology, applied in the direction of control valve, valve device, functional valve type, etc., can solve the problems of increasing leakage points, being susceptible to accidental damage, unreasonable shape design of one-way valve, etc., to improve reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with examples.

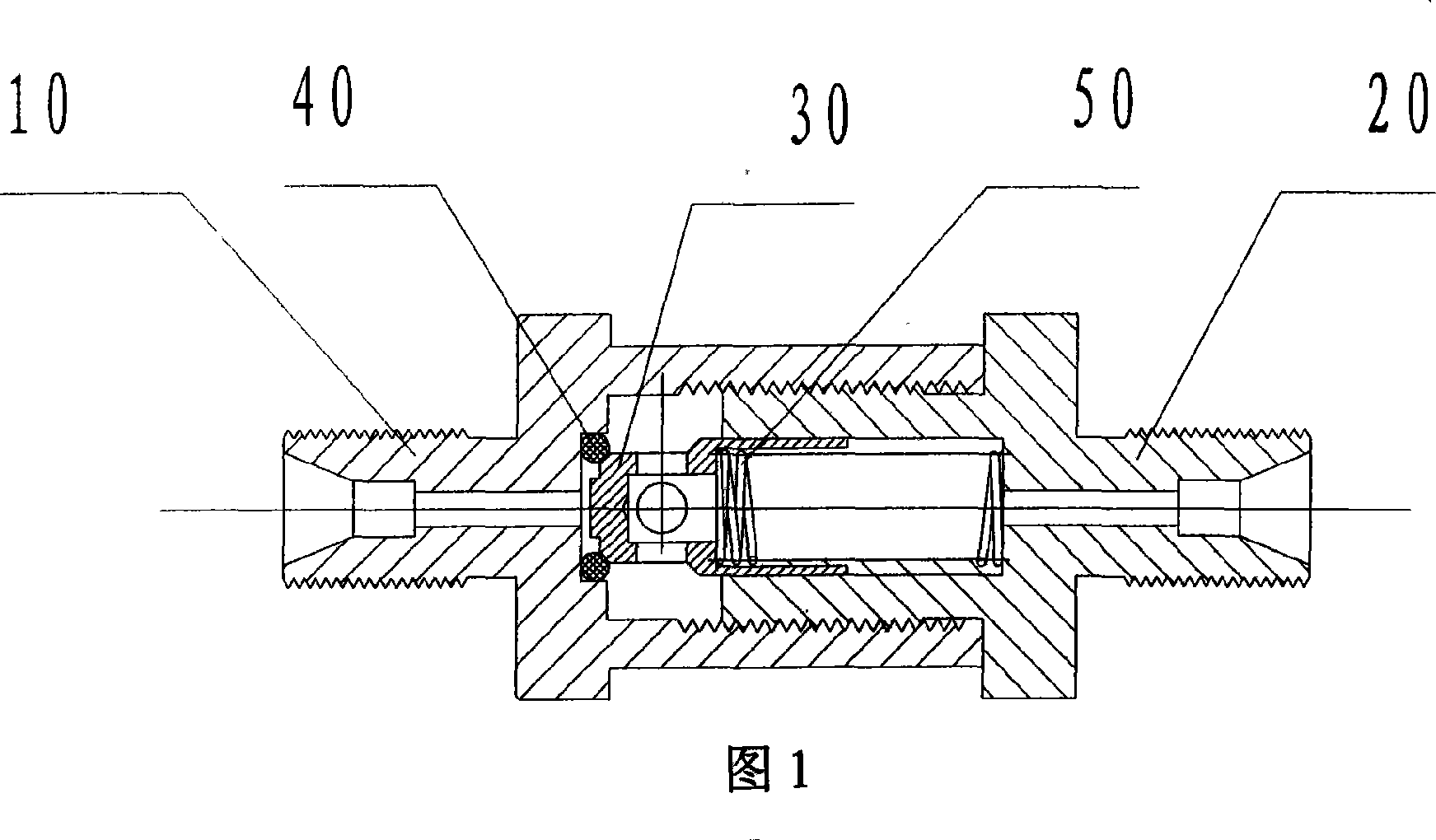

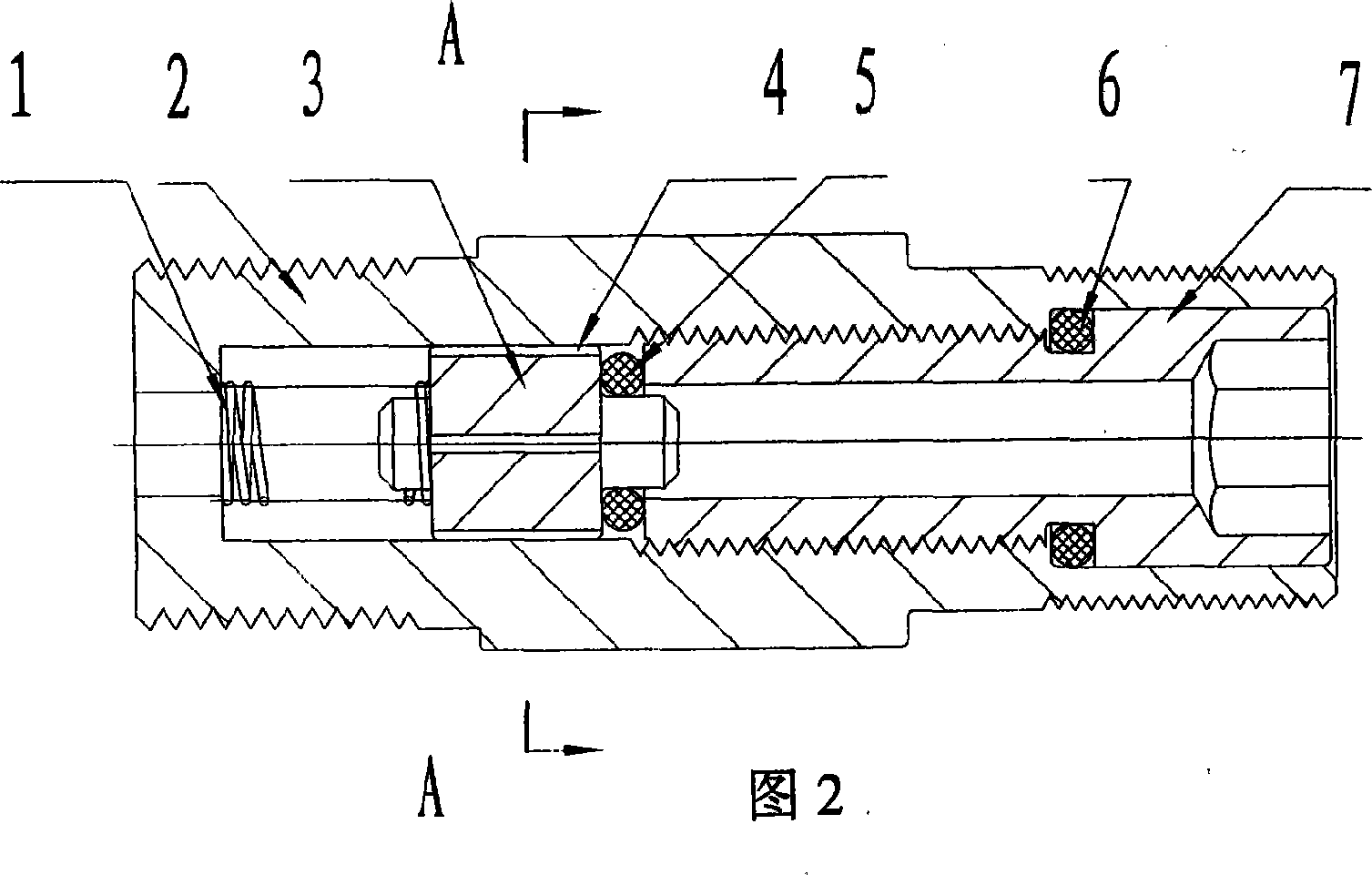

[0025] See Figure 2 and Figure 3: This check valve is composed of an upstream valve body 7, a downstream valve body 2, and a valve core 3. The upstream valve body 7 and the downstream valve body 2 are connected by threads, and the tail of the valve core 3 has a return spring. 1. There is a sealing ring 5 on the spool 3.

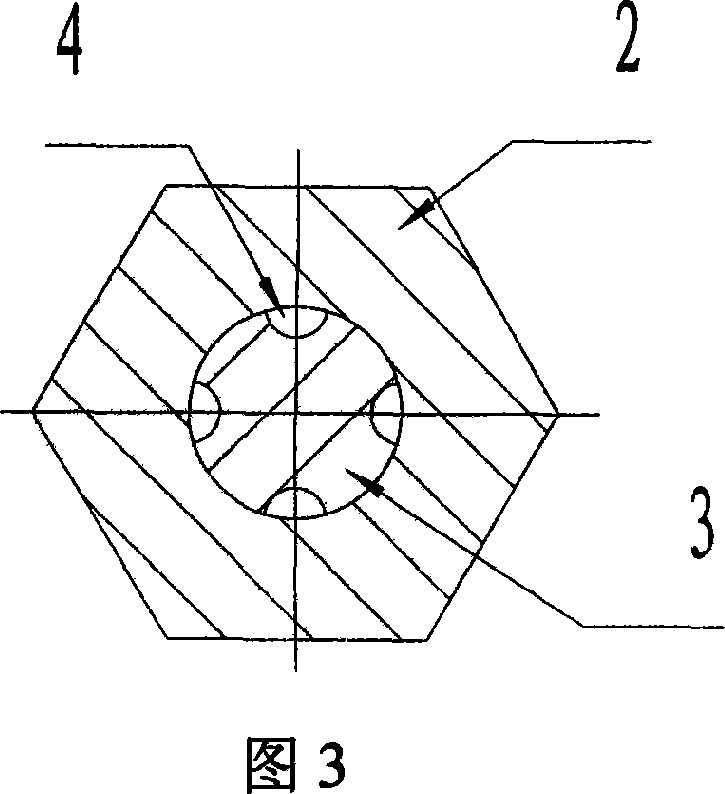

[0026] The main features of the one-way valve are: the valve core 3 is located in the downstream valve body 2 and is slidingly matched with the downstream valve body 2, and several axial grooves 4 are milled on the cylindrical surface of the valve core 3 as medium passages. In this way, when the valve core 3 opens and closes, it is guided by the downstream valve body 2 and remains concentric without swinging. When the valve core 3 is closed, it can be aligned with the sealing surface of the valve seat to ensure good sealing and not easy to leak.

[0027] Another fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com