Armature, rotating electric machine, DC motor, and brushless motor

A technology of armature and armature iron core, applied in the field of armature, rotating electrical machine, DC motor and brushless motor, can solve the problem of increasing the number of armature iron core parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

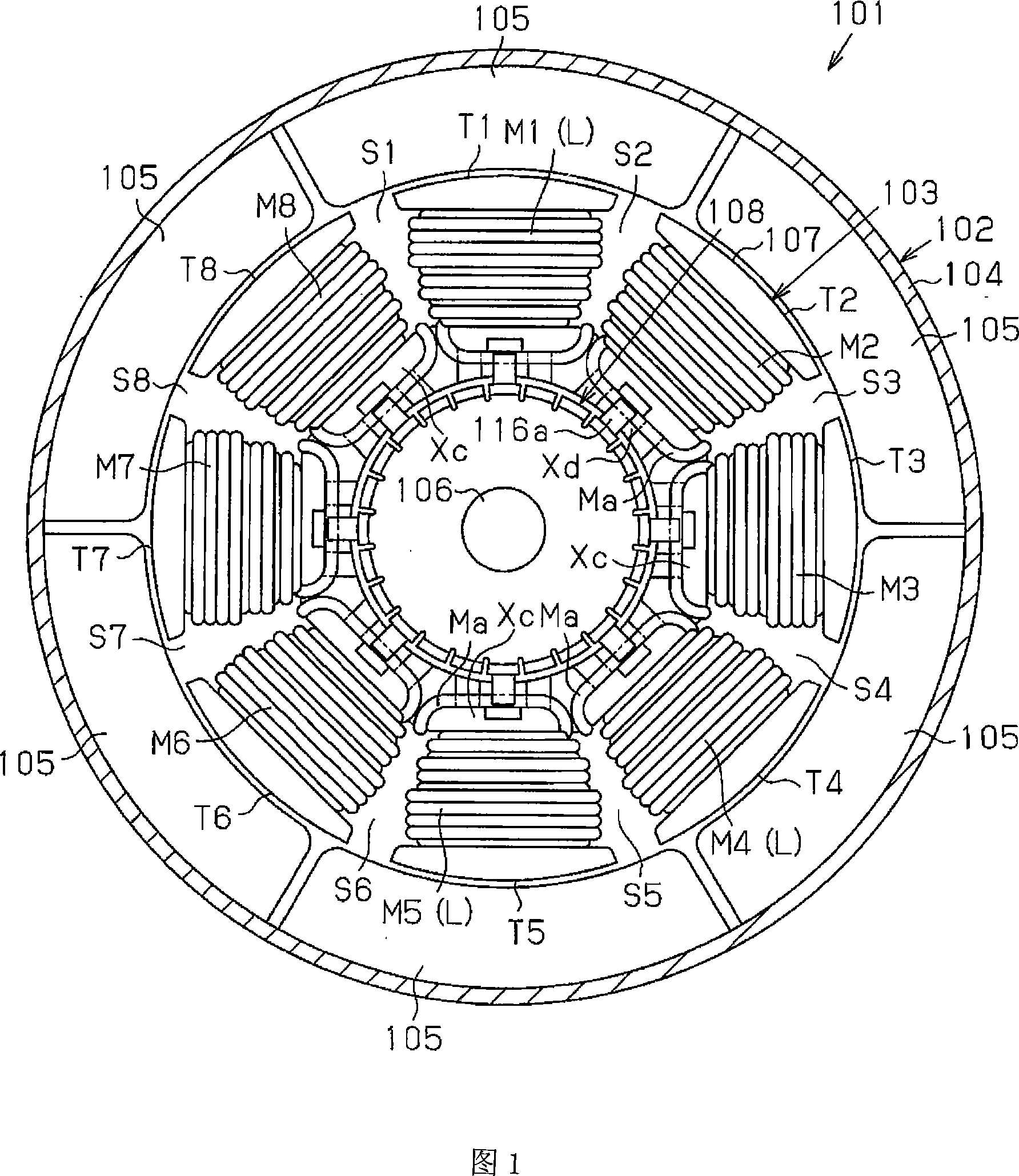

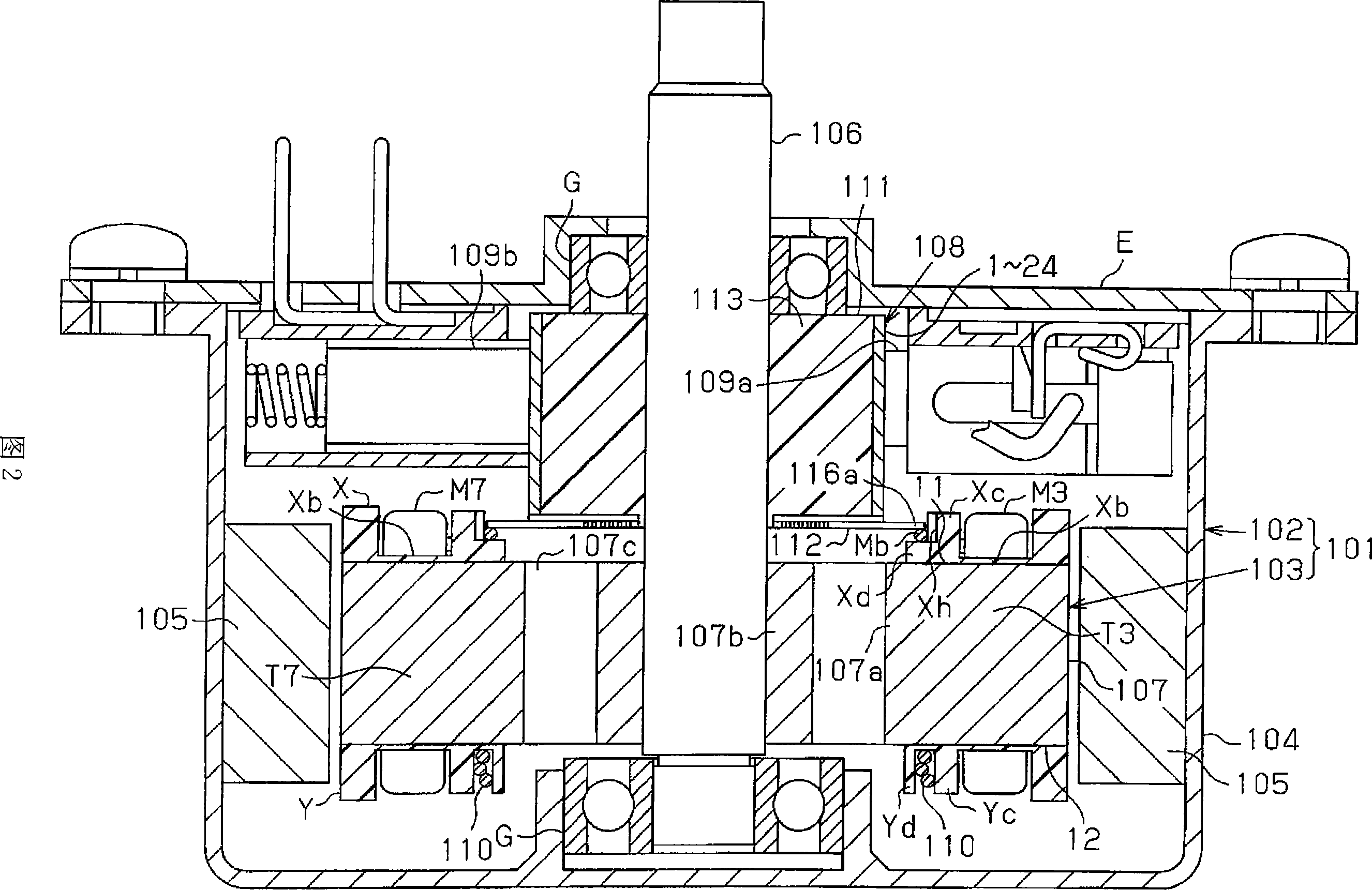

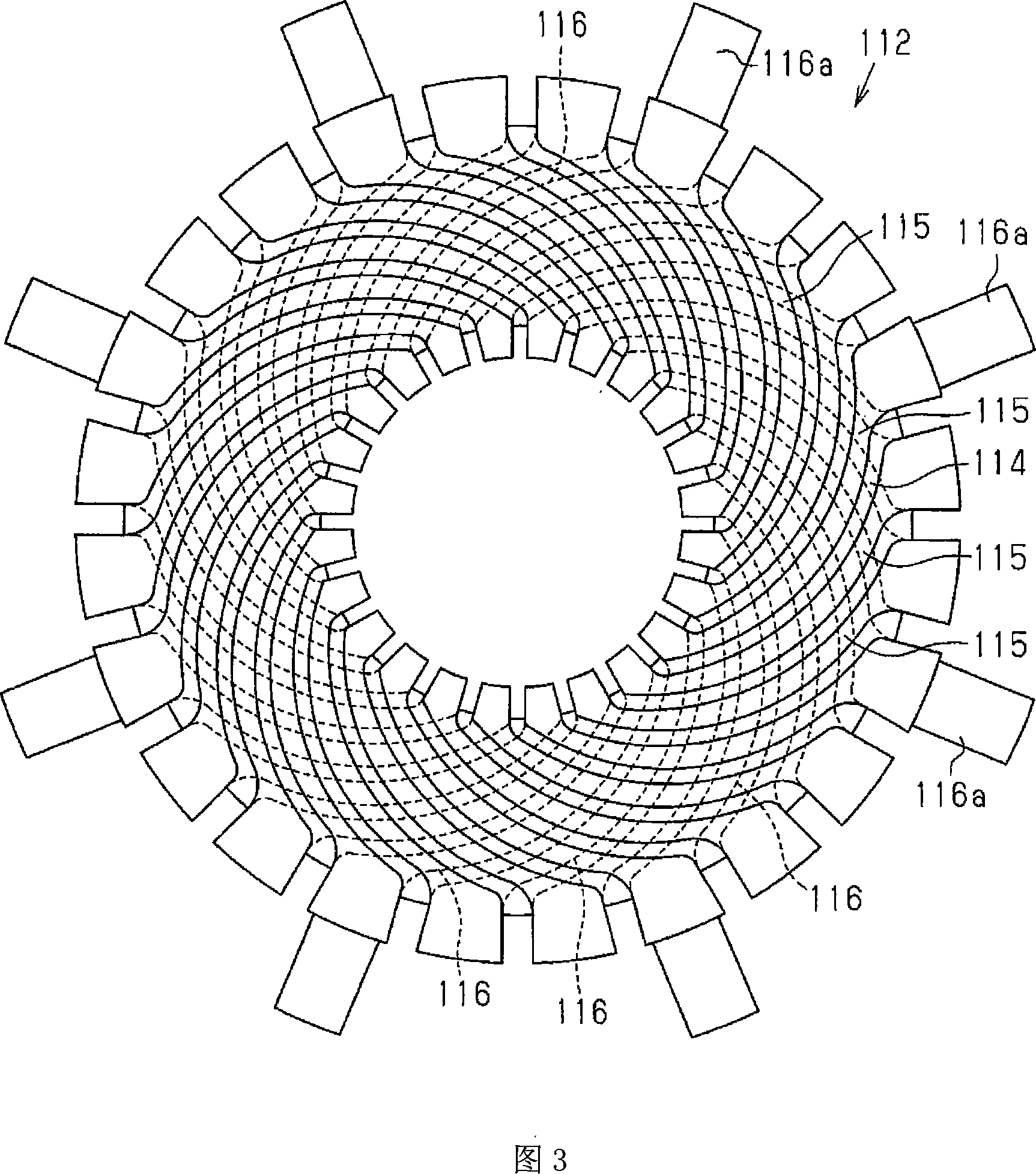

[0056] Hereinafter, a first embodiment of the present invention will be described with reference to FIGS. 1 to 10 .

[0057] As shown in FIG. 1 , a DC motor 101 as a rotating electrical machine has a stator 102 and an armature 103 as a rotor. The stator 102 has a substantially cylindrical yoke cover 104 and a plurality of magnets 105 fixed to the inner peripheral surface of the yoke cover 104 at equal angular intervals. In this embodiment, the number of magnets 105 is six, constituting six poles, and the number of magnetic poles is six.

[0058] As shown in FIG. 1 and FIG. 2 , the armature 103 includes a rotating shaft 106 , an armature core 107 fixed on the rotating shaft 106 , and a commutator 108 also fixed on the rotating shaft 106 . As shown in FIG. 2 , both ends of the rotating shaft 106 are rotatably supported by a pair of bearings G held by the yoke cover 104 and the end cover E that closes the opening of the yoke cover 104 . An anode-side brush 109a and a cathode-si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com