Pulp screen for cooking and digesting papermaking pulp

A technology of pulp screening machine and raw pulp, which is applied in textiles, papermaking, fiber raw material processing, etc., can solve the problems of expanding pollution, reducing cooking temperature, wasting water resources, etc., and achieves the goal of reducing environmental pollution, reducing evaporation, and increasing production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

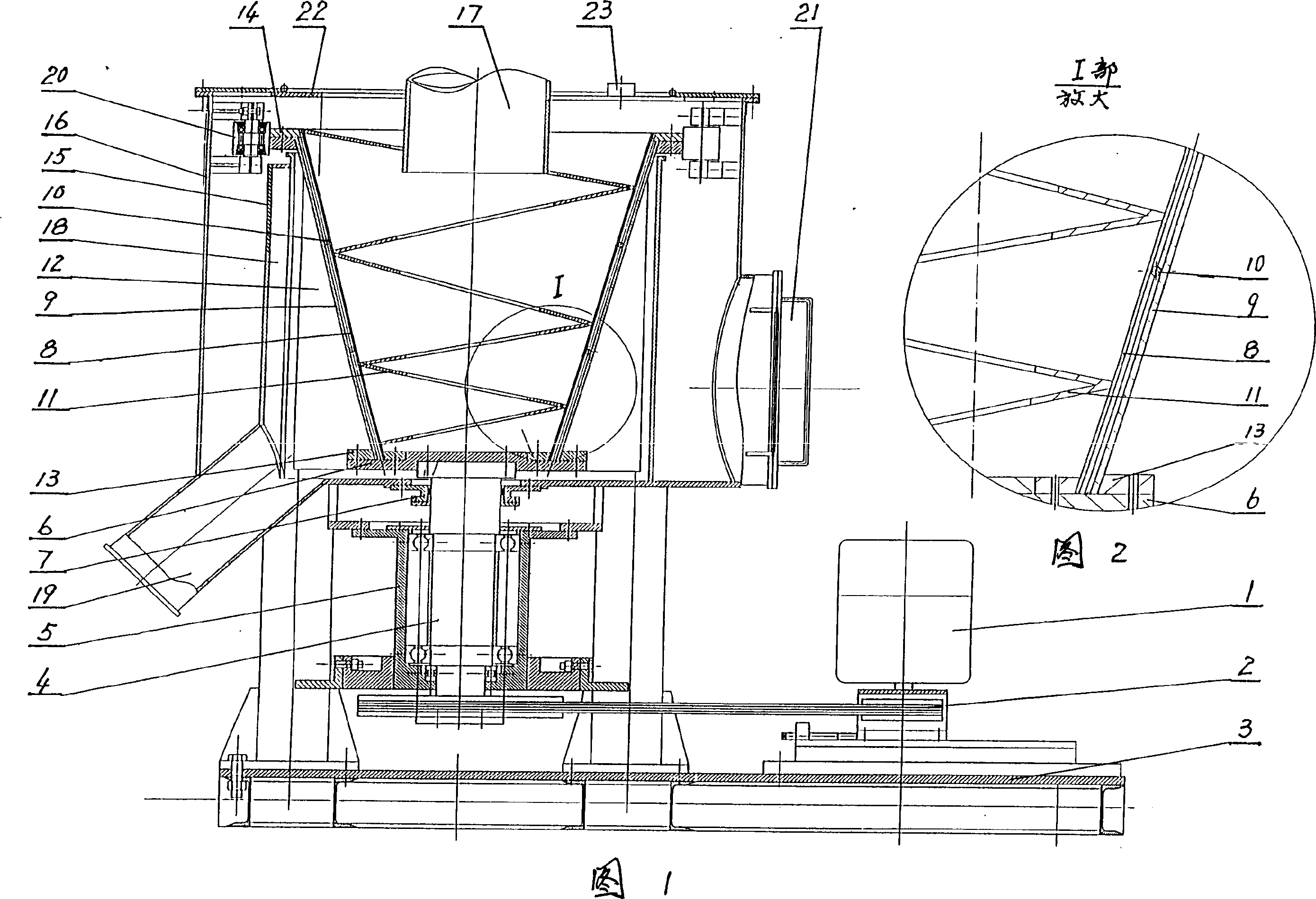

[0016] The accompanying drawing is an embodiment of the present invention, including a motor 1, a transmission device 2, a vertical shaft device, a conical screen device, a separation cylinder device, a frame 3, and the like. The transmission device 2 is a belt transmission structure, including a large pulley, a belt, and a small pulley, and the small pulley is fixed on the motor 1 shaft. The vertical shaft device is composed of a vertical shaft 4, a vertical shaft frame 5, a connecting plate 6, etc., the vertical shaft 4 is installed in the vertical shaft frame 5 through a bearing, and can rotate, the vertical shaft frame 5 is fixed in the frame 3, and the lower end of the vertical shaft 4 is fixed with a transmission device 2 The upper end of the vertical shaft 4 extends into the slurry cylinder 15 of the separation cylinder device and is fixed with a connecting plate 6. A sealing device 7 is arranged between the vertical shaft 4 and the bottom of the slurry cylinder 15. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com