Rapid precise constructing and shaping method for complex curved face product

A technology of complex surfaces and forming methods, applied in 3D modeling, image data processing, special data processing applications, etc., can solve the problem that the surface mesh is not closed, the time to construct the mesh surface is long, and the mesh surface cannot be truly reflected, etc. problems, to achieve the effect of ensuring consistency, avoiding self-intersection and inclusion, and saving judgment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

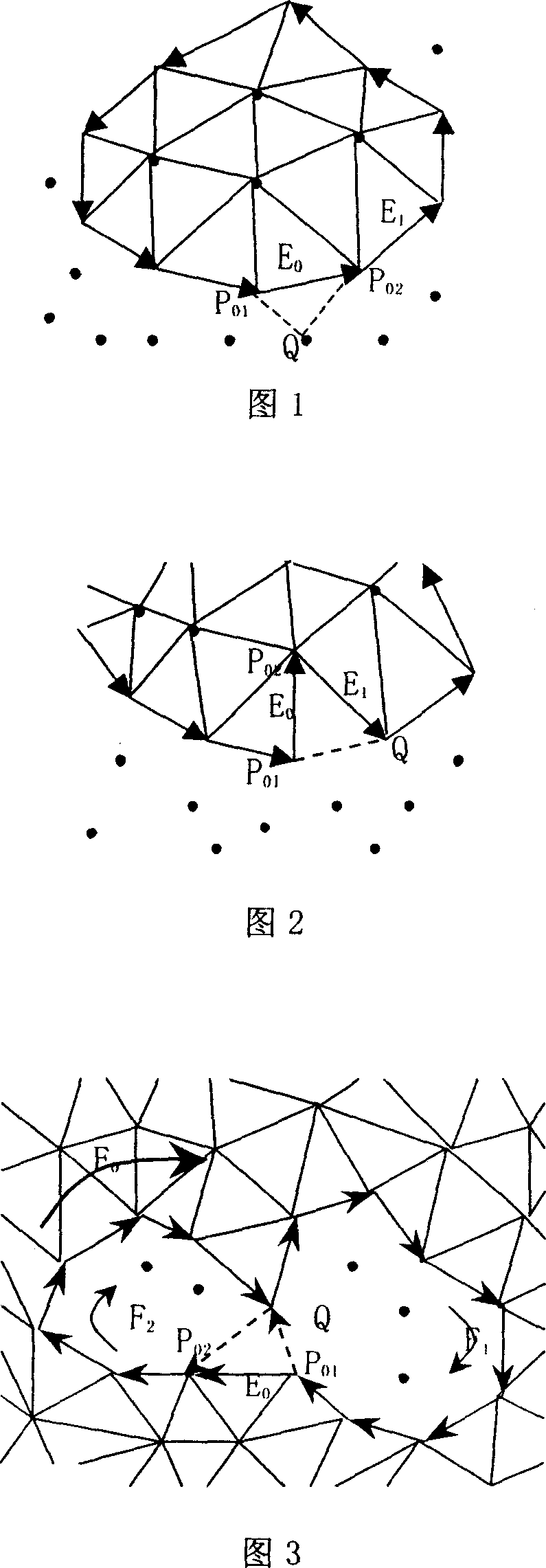

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: Curved surface construction and rapid prototyping are carried out to the human head model, and its experimental steps are:

[0026] 1. Obtain the surface data of the human head model with a laser measuring machine, the number of data points is 40146, and use R * -tree is used as an index structure to establish the topological adjacency relationship of scattered points, and uses the pruning strategy to calculate the K nearest neighbors of each data point. Since the data points retained after collection in places with complex characteristics such as eyes, ears and noses are relatively dense, and in The data points retained in other parts are relatively sparse, so K=20;

[0027] 2. Among the 40146 measured data, select the data point with the largest Z coordinate and find the two points closest to it in space, then connect these three points into a triangle, adjust the arrangement order of the vertices of the triangle so that the normal vector points to Cons...

Embodiment 2

[0032] Embodiment 2: Carry out curved surface construction and rapid prototyping to the Venus head model, its experimental procedure is the same as embodiment 1, just in step 1, obtain the 19928 surface data points of the Venus head model with a laser measuring machine, the number of neighbor points to find is 10; in step 4, the offset thickness of the mesh model is 3mm, and the lighting rendering effect of the generated triangular mesh model is shown in Figure 6, the number of patches is 39473, and the time-consuming is 14s.

Embodiment 3

[0033] Embodiment 3: Carry out curved surface construction and rapid prototyping to the rabbit model. The experimental procedure is the same as that of Embodiment 1, except that in step 1, 34,833 surface data points of the rabbit head model are obtained with a laser measuring machine, and the number of neighbor points to be found is 12. In step 4, the offset thickness of the mesh model is 3mm, and the lighting rendering effect of the generated triangular mesh model is shown in Figure 7, the number of patches is 134456, and the time-consuming is 15s.

[0034] The rapid and accurate construction and molding methods of other complex curved surface products are the same as above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com