Polypropylene resin laminated film and its manufacturing method

A technology of polyolefin resin and polypropylene, applied in the direction of synthetic resin layered products, chemical instruments and methods, lamination, etc., can solve the problem of poor dispersion of inorganic particles, decreased packaging operability, and mutual adhesion of films etc. to achieve the effects of excellent transparency, good sliding properties, and excellent anti-blocking properties

Active Publication Date: 2010-12-01

TOYOBO CO LTD

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, polypropylene-based resin films have disadvantages such as poor anti-blocking properties, a phenomenon in which the films stick to each other (so-called blocking phenomenon) easily occurs when the films are stacked, and handling properties such as packaging are sometimes significantly reduced.

However, the polypropylene resin obtained by the gas-phase method using a highly active catalyst has a large average particle size, a narrow particle size distribution, and a small amount of fine powder. Therefore, in order to manufacture a polypropylene-based resin film like Patent Document 1, an inorganic In the case of inorganic particles, there is a disadvantage that the dispersibility of the inorganic particles is deteriorated

Method used

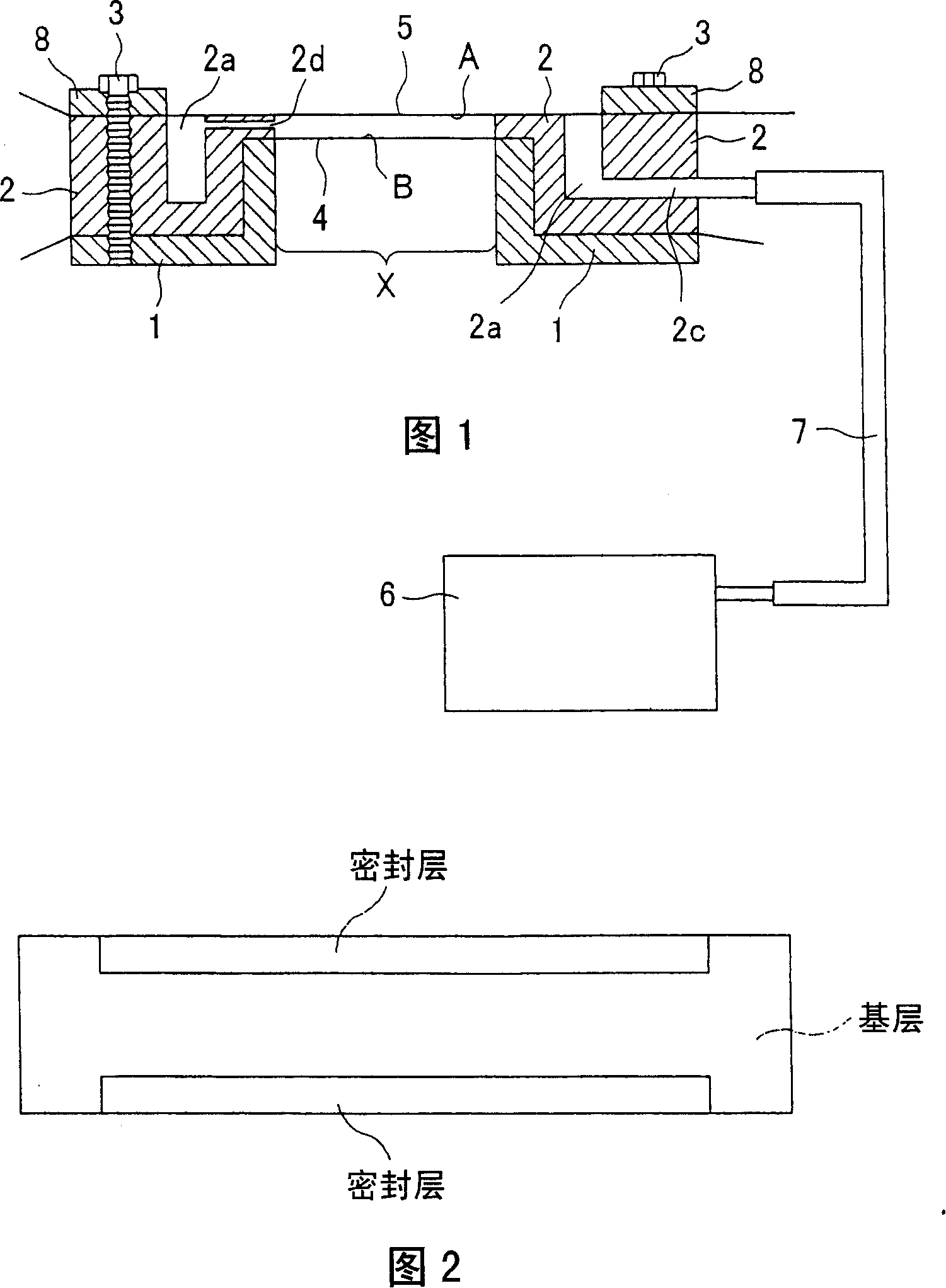

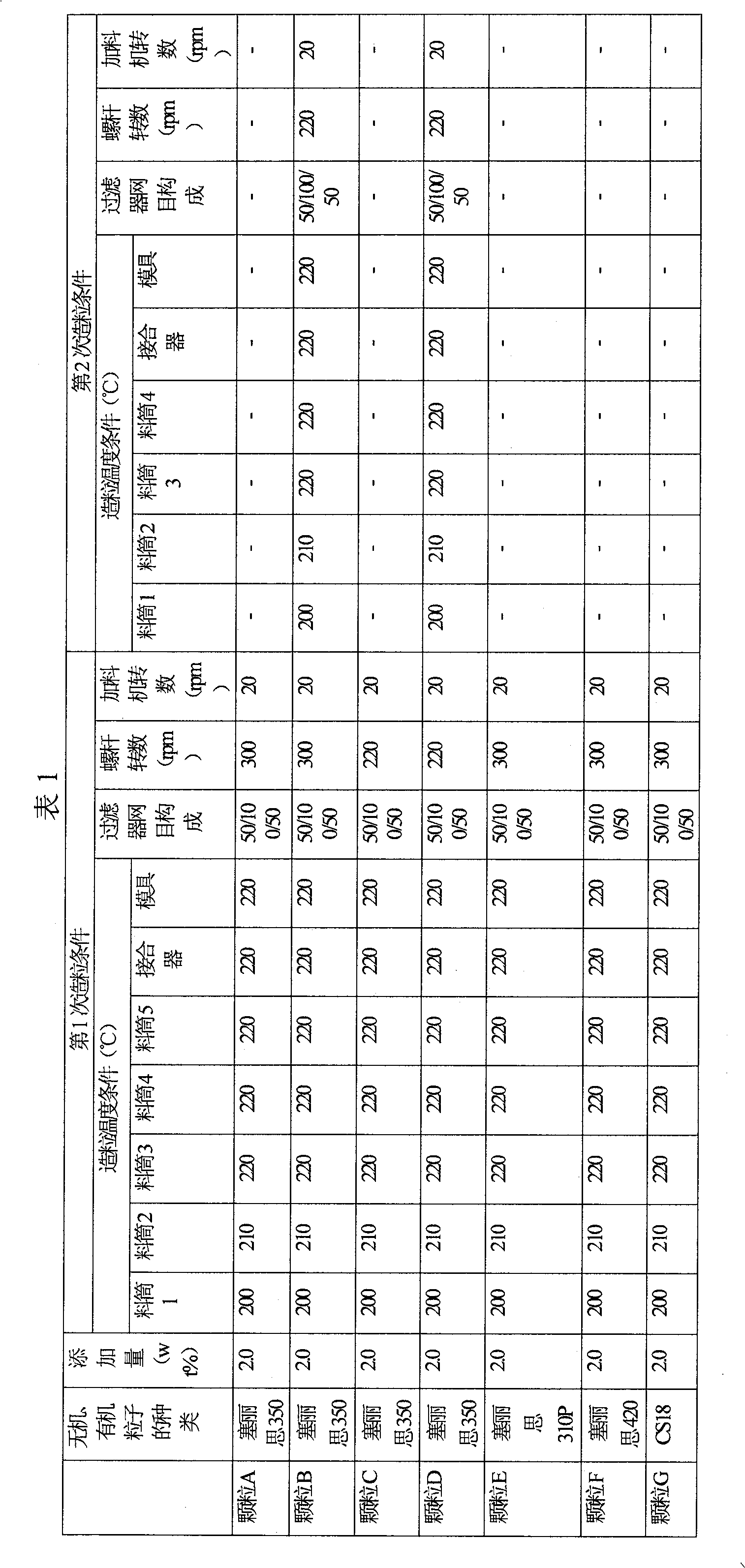

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

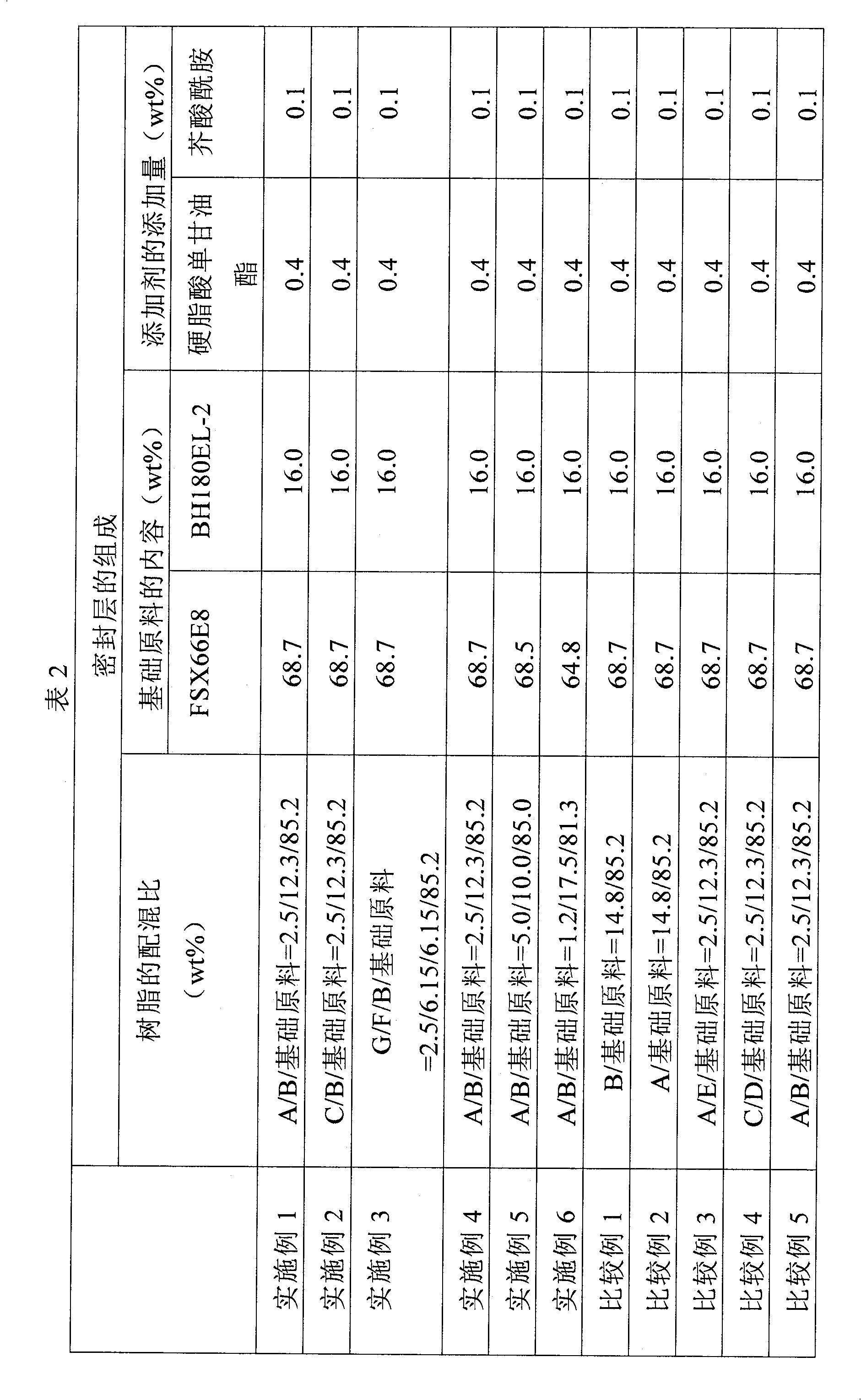

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Login to View More

Abstract

The invention provides polypropylene resinoid film membrane, which made up from polypropylene resinoid, and it is use gas-phase method, it is keen price and highly effective, good at nonstick and glider, While coiling to be coil the film membrane convolve is crease-resist, while bag forming and printed processing the working quality is well. The polypropylene resinoid laminate film in this invention laminate seal course which use polyolefin resinoid as body on positive and negative faces of base which use polypropylene resinoid as body. Furthermore, the polypropylene resinoid which constitutes foot layer and seal course is produced by gas-phase method. Furthermore, adjust it and make sure the coefficient of dynamic friction, air aerofluxus exponential and brume degree values which mensurated at 40 degree centigrade satisfy the enactment conditional.

Description

Polypropylene-based resin laminated film and method for producing the same technical field The invention relates to a film for packaging, in particular to a film with anti-fog properties, good sliding properties, anti-blocking properties and transparency, suitable for packaging including vegetables, roots, fruits, flowers, flowers, mushrooms, fish, meat, etc. Films of fresh plant or animal fresh products (hereinafter referred to as fresh products). Background technique Films made of polyolefin resins are widely used as packaging materials for various items represented by food. In particular, polypropylene films are widely used mainly in the field of food packaging because of their excellent mechanical properties, optical properties such as transparency and gloss, and food hygiene properties such as gas barrier properties and odorlessness. However, polypropylene-based resin films have disadvantages in that they are poor in anti-blocking properties, tend to cause films to s...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B65D65/40B29C55/12B29C69/02B32B27/32B29C47/06B32B38/12B32B37/00B32B27/18B29C47/56B29C47/12B29C48/30

Inventor 河井兼次大木祐和野濑克彦

Owner TOYOBO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com