Sound absorbing and insulating barrier

A technology for sound absorption and sound insulation, which is used in noise absorption devices, buildings, etc., can solve the problems of fatigue damage of sound absorption and insulation panels, weak anti-vibration ability, and many stress cycles, etc., to achieve economical and environmental protection. Excellent, strong wind pressure resistance, less increase in static load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

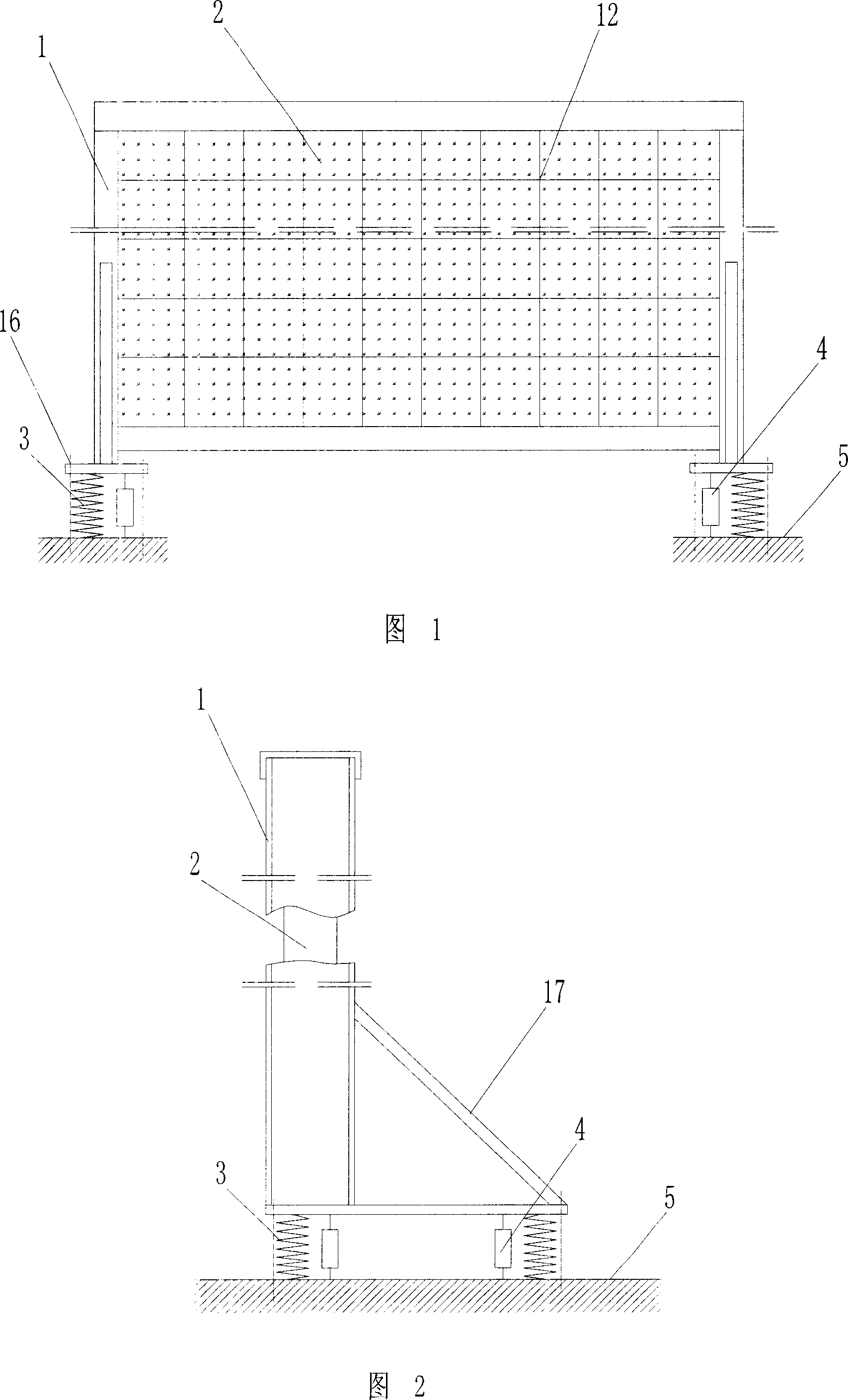

[0026] The sound-absorbing and insulating barrier of the present invention as shown in Fig. 1 and Fig. 2 includes a supporting frame 1 and a sound-absorbing and insulating panel 2, and the sound-absorbing and insulating panel 2 is arranged in the supporting frame 1, between the supporting frame 1 and the base 5 An elastic element and a damping element are arranged in parallel, wherein the elastic element is a spring 3 and the damping element is a damper 4 . The support frame 1 and the base 5 are pre-tightly connected together by using anchor bolts 16 (not specifically shown in the figure) preset in the base 5 . In order to strengthen the bending rigidity of the bottom of the supporting frame, the lower part of the supporting frame is provided with oblique reinforcing ribs 17, so that the lower part of the supporting frame forms triangular outriggers.

[0027] When the external exciting force formed by vehicles passing or wind blowing acts on the sound-absorbing barrier, due to...

Embodiment 2

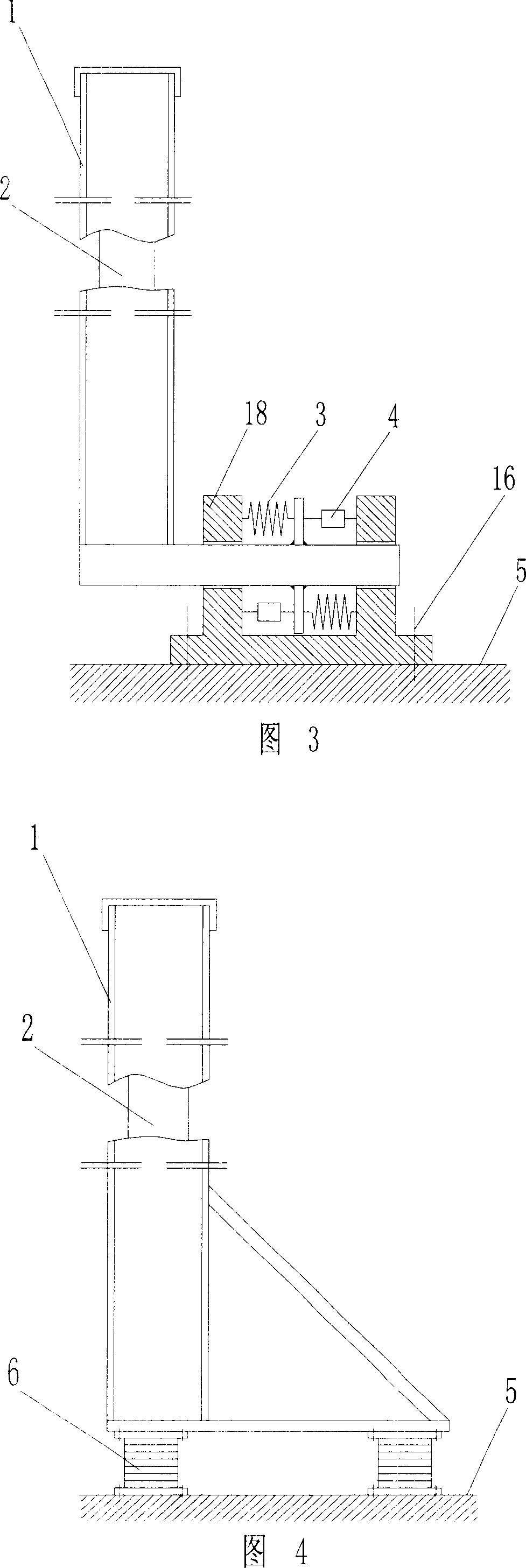

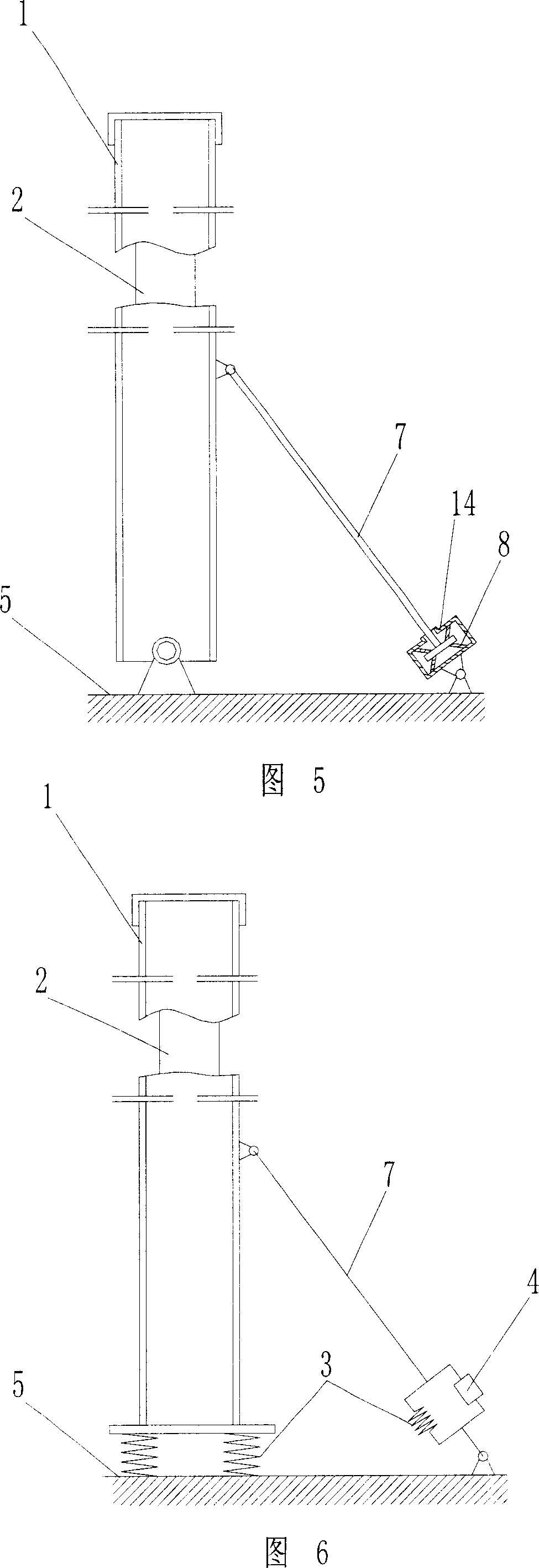

[0034] As shown in Figure 3, the difference between the sound-absorbing and insulating barrier of the present invention and Embodiment 1 is that a guiding device guide support 18 is provided between the legs of the support frame 1 of the sound-absorbing barrier and the base 5, and on the guide support 18 There are horizontal guide holes along the normal direction of the sound-absorbing and sound-insulating panel, so that the legs of the support frame can move horizontally relative to the guide support 18, and the corresponding springs 3 and dampers 4 are also arranged horizontally on the legs and the guide support. Between 18, guide support 18 and base 5 are fixedly connected with bolts.

[0035] After the sound-absorbing and insulating panel 2 bears the external excitation force, it drives the support frame 1 to elastically translate along the normal direction of the sound-absorbing and insulating panel, and its inertial mass balances most of the exciting force, while compress...

Embodiment 3

[0038] As shown in Figure 4, the difference between the sound-absorbing and insulating barrier of the present invention and the first embodiment is that a laminated rubber support 6 is arranged between the support frame 1 and the base 5, such as the patent No. ZL3112549 announced on September 7, 2005. The shock-isolation bearing described in the Chinese patent No. 2 can be regarded as an integration of elastic elements and damping elements.

[0039] The laminated rubber support 6 has great rigidity in the vertical direction, but has good elasticity in the horizontal direction, so it acts as a guide in the horizontal direction. Because it can achieve large horizontal shear deformation and limit the swing of the sound-absorbing and insulating barrier, it has guiding function, elastic function and damping function at the same time. Therefore, when the sound-absorbing and insulating barrier is subjected to external excitation force, the laminated rubber bearing 6. Large horizontal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com