Automatic washing blowing filling sealing machine for injection bottle

An automatic flushing and injection technology, which is applied in bottling machines, liquid treatment, bottle filling, etc., can solve the problems of large equipment investment and space occupation, high production cost, and complex structure, and achieves convenient operation, light weight, and small volume. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

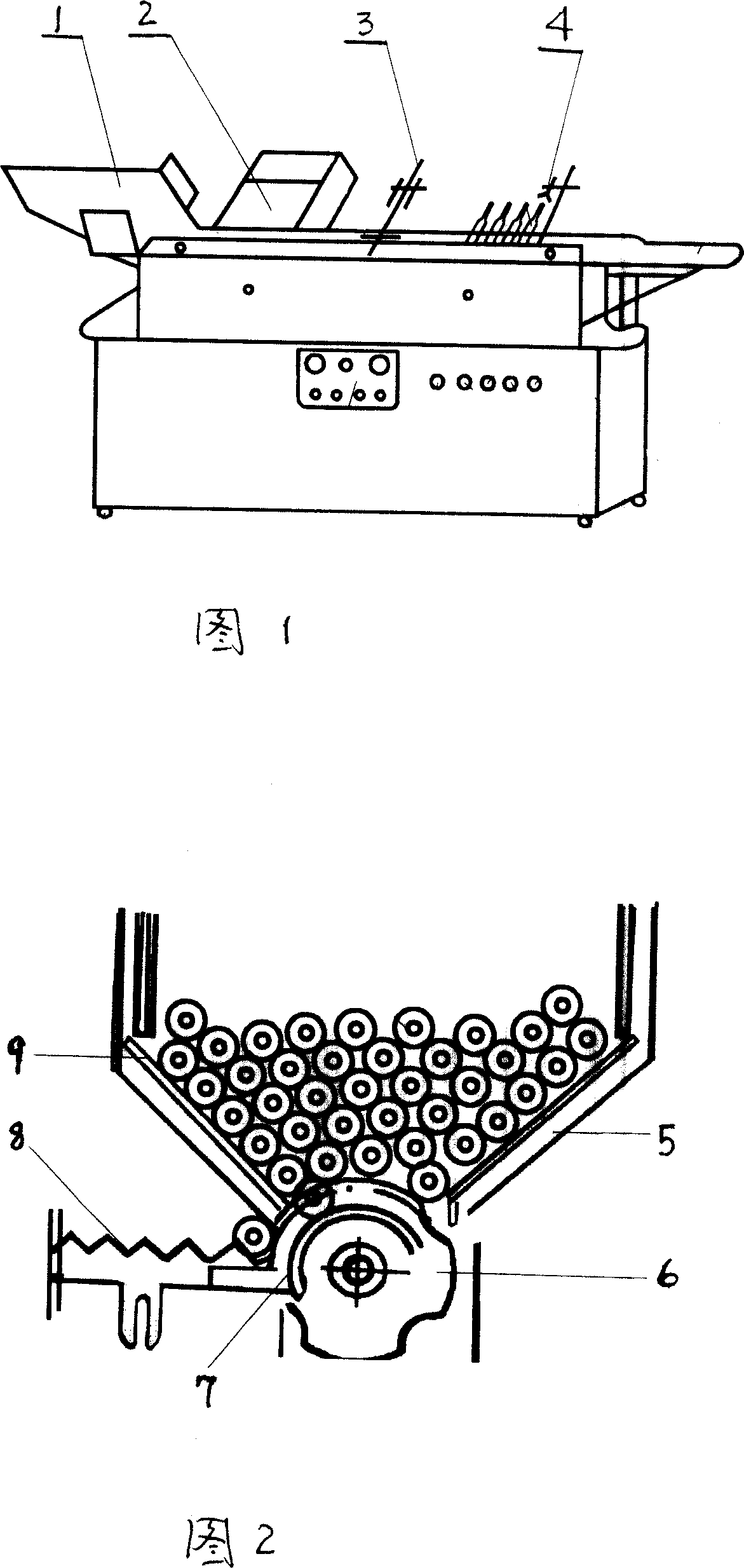

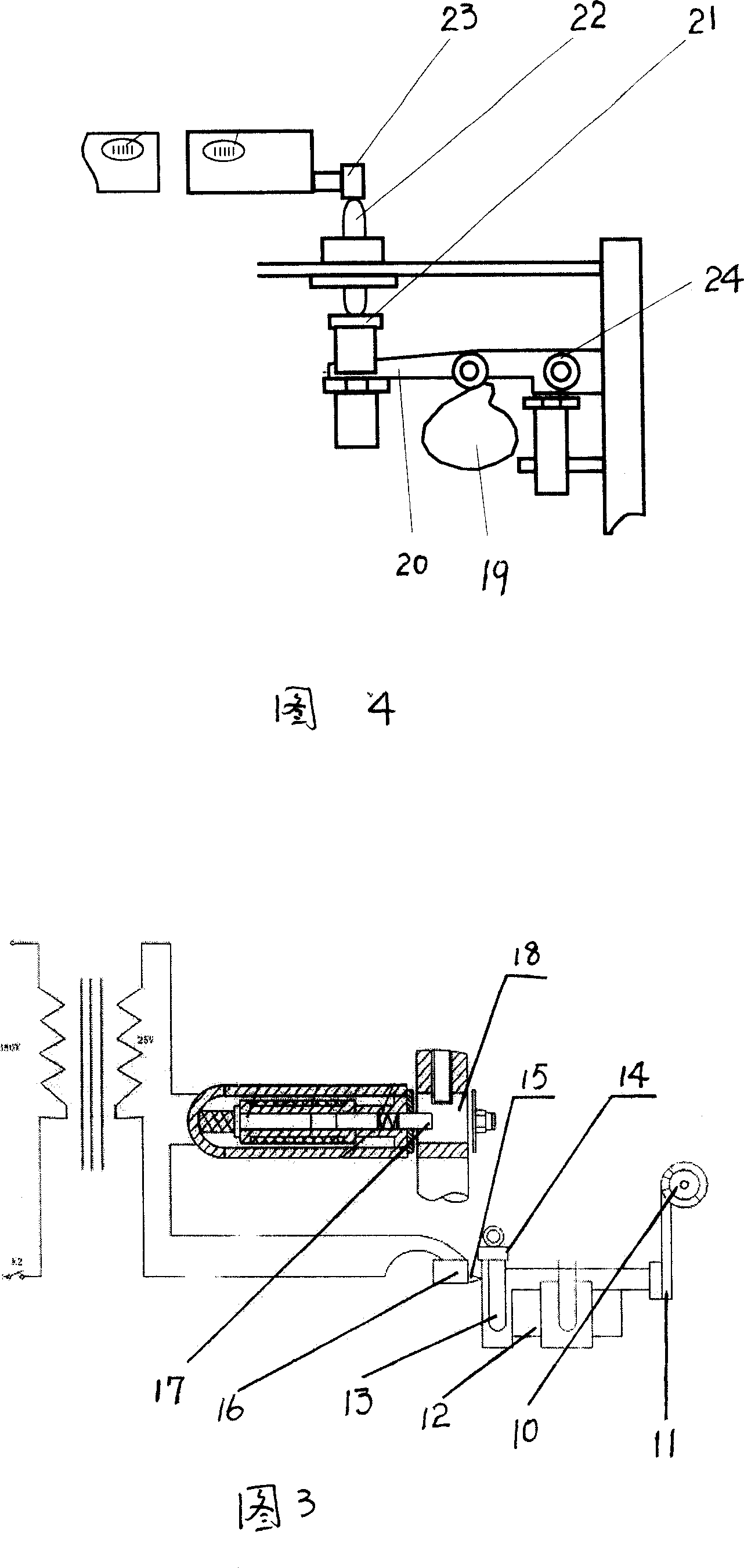

[0012] As shown in the figure, the present invention includes a bottle feeding mechanism 1, a rinsing and drying mechanism 2, a filling mechanism 3 and a sealing mechanism 4 which are sequentially connected by transmission. Tooth plate 8, movable fence 9 is set on the inner wall of bottle feeding bucket 5, the adjustable distance between movable fence 9 and turntable 6 is suitable for injection bottles of different specifications to pass through, turntable 6 is connected with positioning tooth plate 8, adjusts The rod 7 is opposite to the injection bottle neck; in production, when changing liquid medicine bottles of specifications such as 5ml, 10ml, and 20ml, adjust the movable fence 9 on the bottle feeding bucket 5 to the liquid medicine bottle of the required specification on the turntable 6 When the liquid medicine bottle is sent to the positioning tooth plate 8 by the turntable 6, the bottle body of the liquid medicine bottle just touches the adjustment gauge mounted on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com