Production method for decreasing brown change of pineapple concentrated juice

A production method and technology for concentrated juice, applied in chemical instruments and methods, other chemical processes, food science, etc., can solve the problems affecting the utilization of pineapple peel juice, difficulty in production management, browning of pineapple juice, etc., and improve the gloss of juice. , the effect of reducing the loss of juice and reducing the astringency of the juice

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

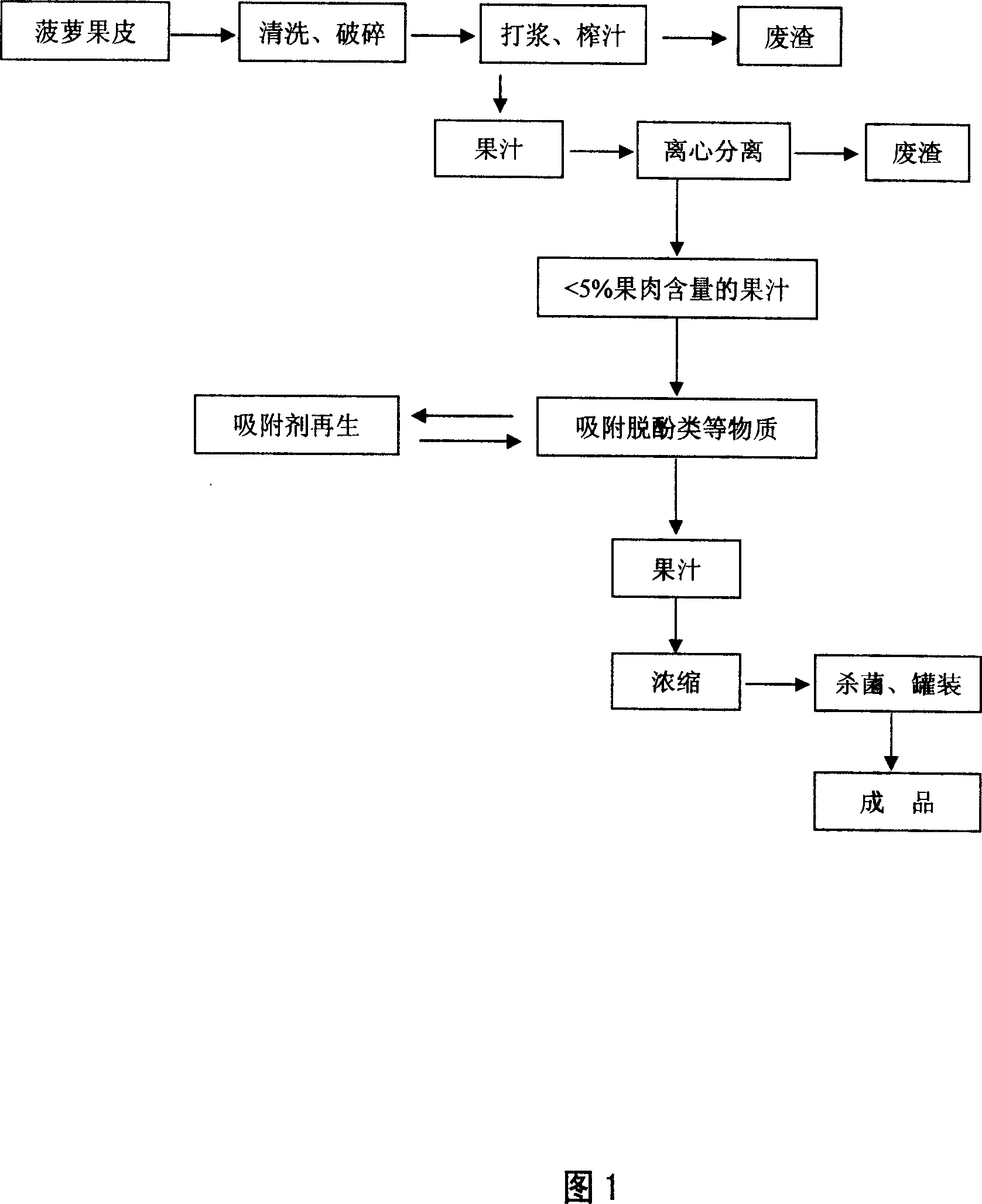

Embodiment 1

[0027] Take the leftovers such as pineapple peel and pineapple core, crush, squeeze the juice, and inactivate the enzyme for 30 seconds, and then use a plate and frame filter to separate to obtain pineapple juice. The sugar content of the juice is 6%, and the polyphenol content is 973mg / L. Continuously flow the juice through the adsorption tank equipped with XDA-2 macroporous resin, the volume of the resin is 3% of the volume of the juice, the adsorption time is 25 minutes, the juice obtained after separation is directly concentrated to 60°Bx, then sterilized and canned Obtain pineapple juice concentrate product. The browning index of the finished fruit juice is 0.225, the color difference value L=18.34, a=0.97, b=5.95. XDA-2 macroporous resin can be reused after being regenerated with 70% ethanol and 2% sodium hydroxide for 8 hours.

Embodiment 2

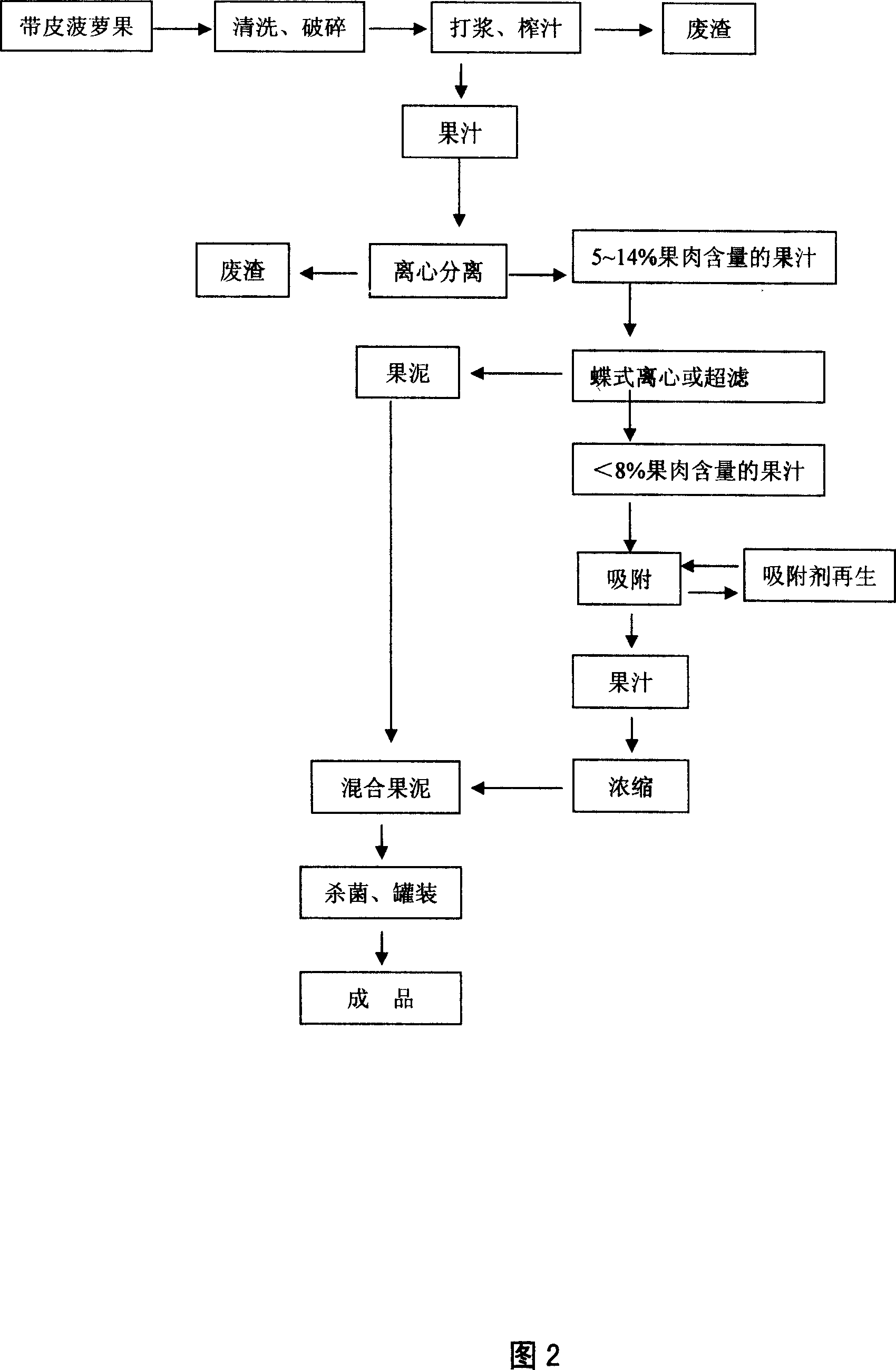

[0029] Crush the pineapple with skin, squeeze the juice, inactivate the enzyme at 80°C for 30 seconds, and filter it with ultrafiltration to obtain clear juice. Take 1% of the juice volume and mix polyvinylpolypyrrolidone (PVPP) with the juice, and the adsorption time is 5 minutes , and then filter and separate the fruit juice and PVPP. Using this continuous operation, phenolic substances such as catechols and anthocyanins can be partially removed. The clear juice obtained through filtration is concentrated to 70 ° Bx, and then sterilized and canned to obtain Clear pineapple juice concentrate product. The browning index of the finished fruit juice is 0.189, the color difference value L=20.11, a=0.36, b=6.97. PVPP can be reused after being regenerated with 1mol sodium hydroxide aqueous solution.

Embodiment 3

[0031] On the 20T / h production line of a juice factory, pineapple fruit with skin is used for juice production. The fruit juice separated by the centrifuge was detected, the pulp content was 7%, the sugar content was 12%, and the polyphenol content was 867mg / L. The adsorption tank is filled with polyamide, and the fruit juice after centrifugation with a horizontal screw separator is taken for continuous adsorption treatment. The adsorption time is 15 minutes. The absorbed fruit juice is concentrated, sterilized, and canned to obtain a finished product. After testing, the browning index of the finished fruit juice is 0.205, the color difference value L=23.13, a=0.67, b=6.69, the pulp content is 7%, the sugar content is 62.5%, and the browning degree of the fruit juice is greatly reduced. The polyamide is regenerated by using 70% ethanol and 2% sodium hydroxide aqueous solution, and the regeneration time is 10 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com