Direct dimethyl ether fuel cell system

A fuel cell system and fuel cell technology, applied in fuel cells, circuits, electrical components, etc., can solve problems such as increasing the complexity of the system structure, waste of dimethyl ether fuel, and potential safety hazards, and achieve the elimination of adverse effects, convenient replacement, The effect of avoiding leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

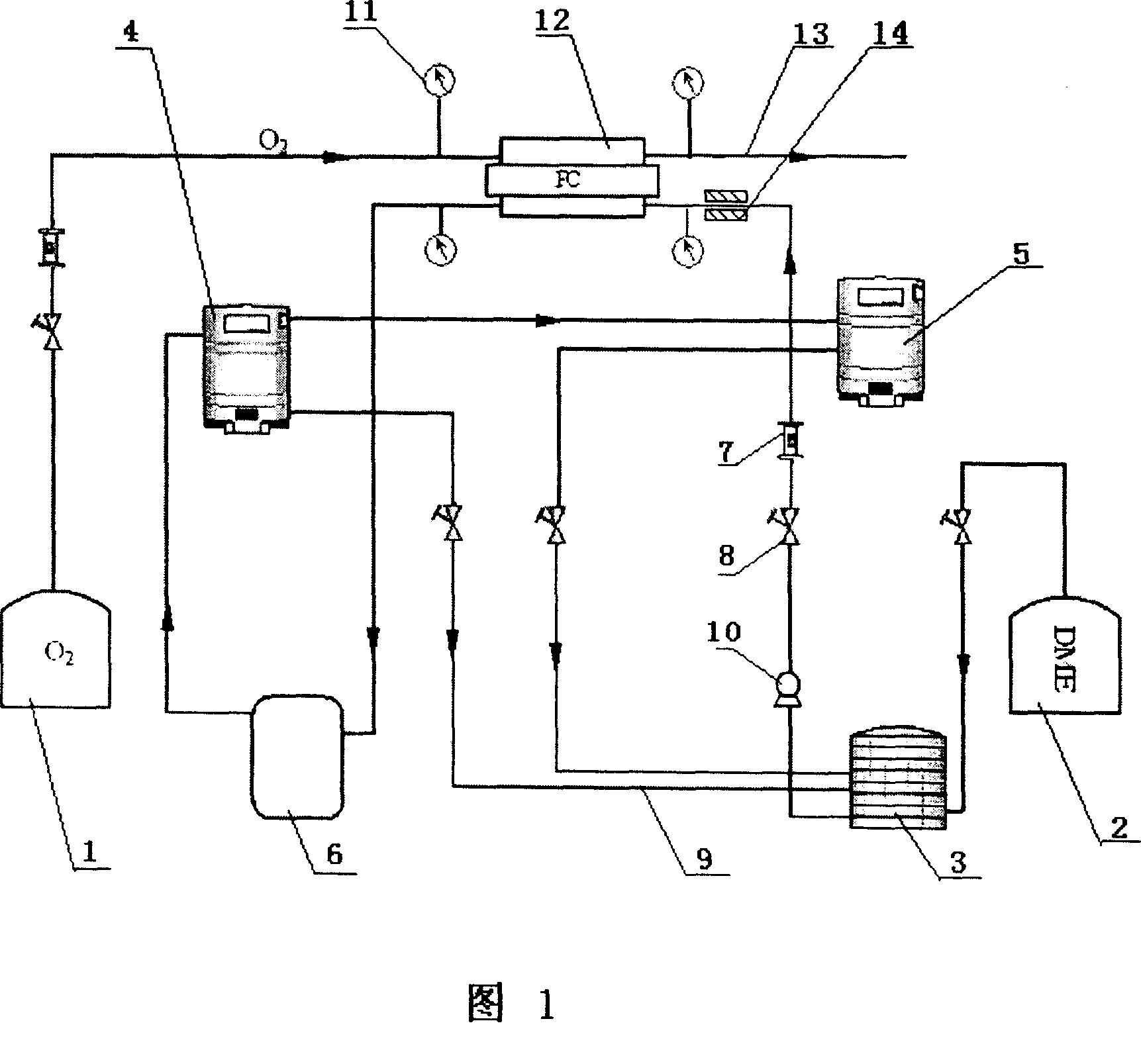

[0016] 1. Material supply device 2, dimethyl ether cylinder 3, pressure tank 4, gas-liquid separation tank 5, purification tank 6, cooling tank 7, flow meter 8, control valve 9, pipeline 1O, constant flow pump 11, pressure gauge 12 , fuel cell 13, discharge pipe 14, pipe heating device

[0017] The pipeline 9 adopts a stainless steel pipe with a diameter of 6mm. The pressure tank 3 has a volume of 5L, and about 2L of distilled water is added therein. NaOH solution. The dimethyl ether cylinder 2 is connected to the pressure tank 3 through the control valve 8, and the pressure tank 3 is connected to the anode inlet of the fuel cell 12 through the pipeline 9 provided with the constant flow pump 10, the flow meter 7 and the control valve 8 to supply the material. The supply device 1 adopts an oxygen cylinder, and the oxygen cylinder is connected to the cathode inlet of the fuel cell 12 through a pipeline 9 provided with a flow meter 7 and a control valve 8 to supply materials for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com