Laser outer diameter detecting instrument

A laser detection head and detector technology, applied in instruments, measuring devices, optical devices, etc., can solve the problems of poor stability, high work intensity, low efficiency, etc., and achieve high precision, slow solution speed, and high economic benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

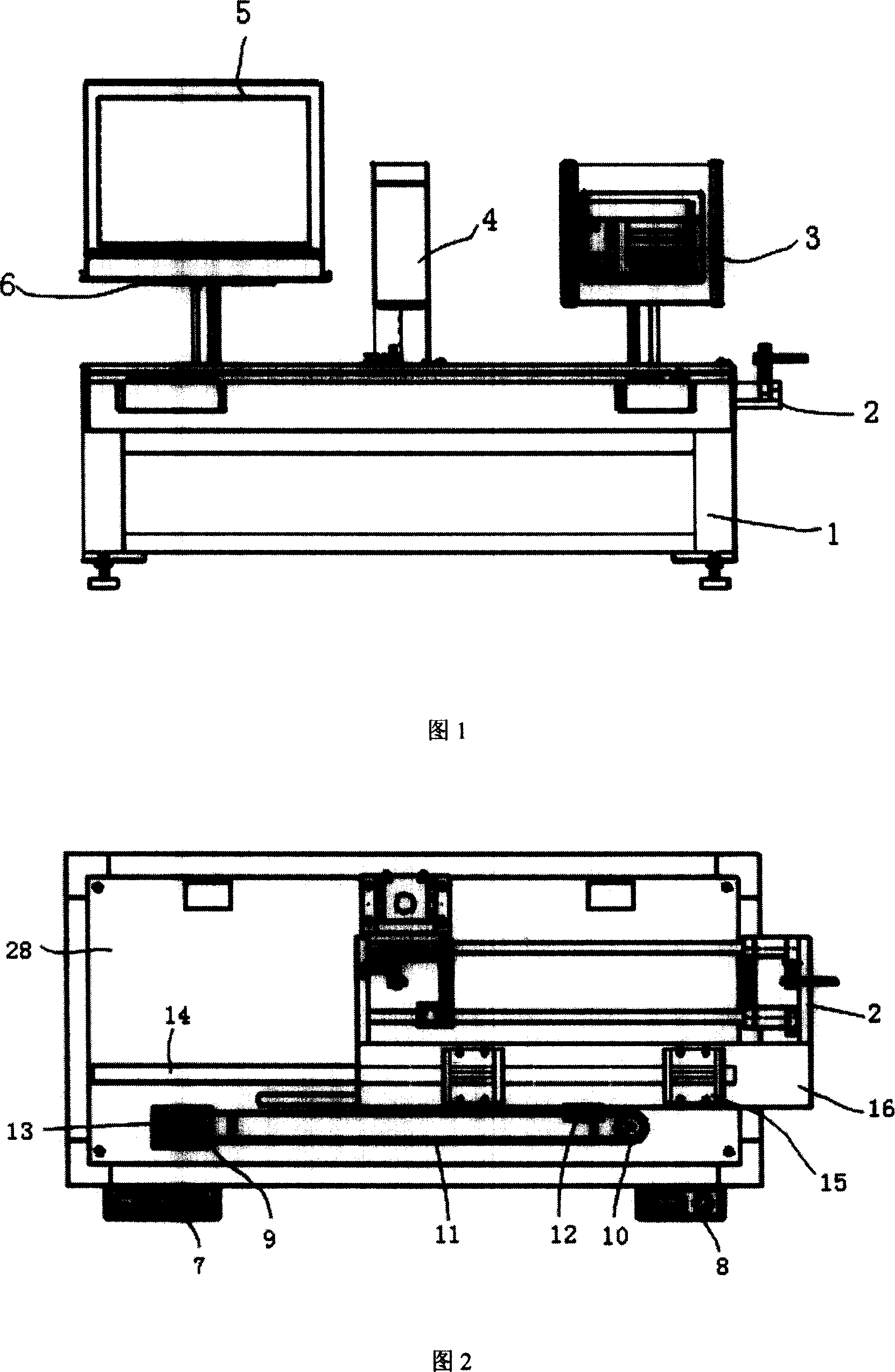

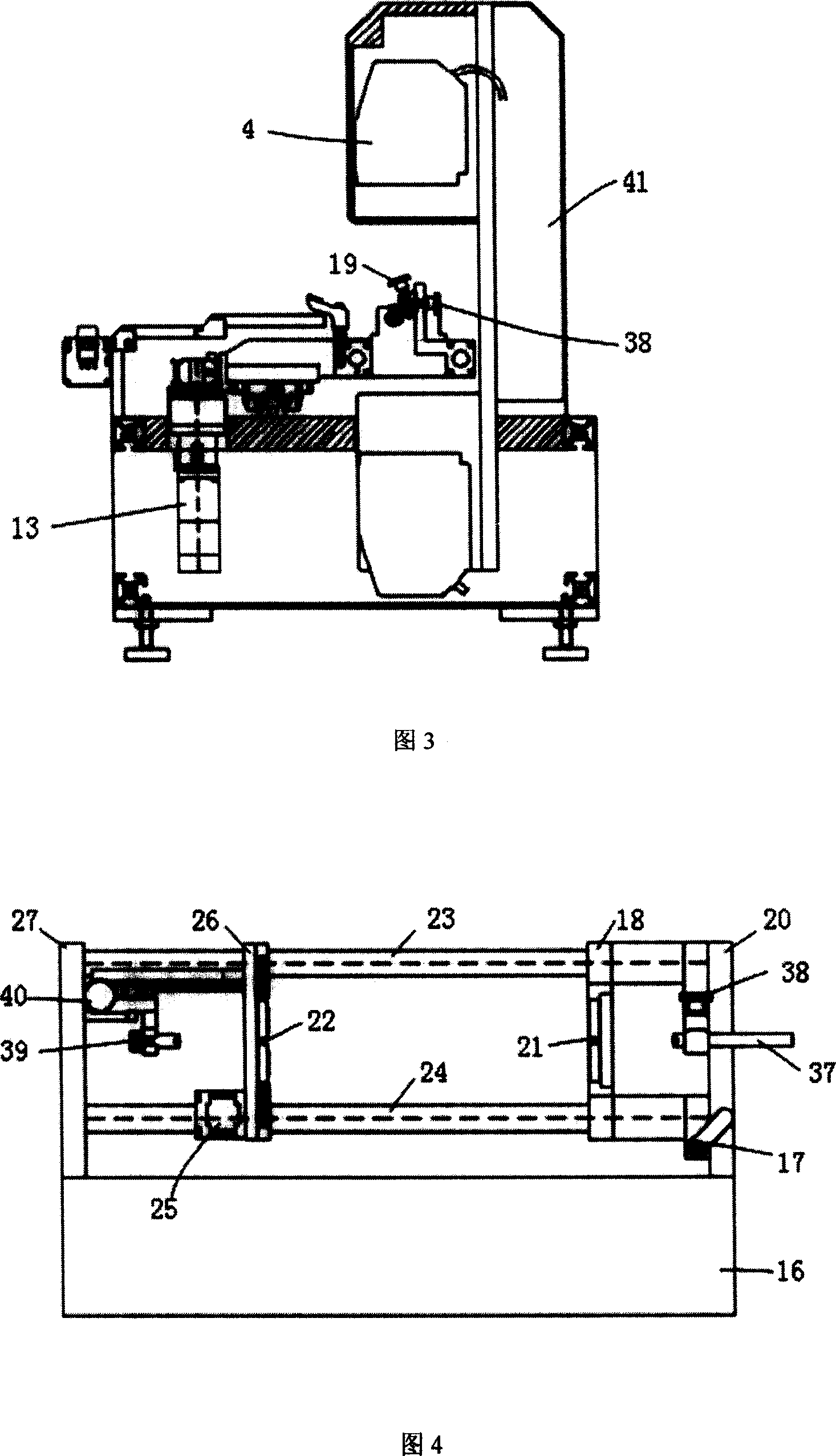

[0028] As shown in Fig. 1, Fig. 2 and Fig. 3, the main body of the laser outer diameter detector includes a main box part 1, a fixture part 2, a control device, a laser controller 3, and a laser detection head 4.

[0029] The main box part 1 includes a peripheral support frame, on which there is a main support plate 28, and a control device is arranged inside the cabinet, and the control device includes a servo driver 33, a step driver 34, a CPU-PLC control system 32, a computer 5, and a laser detection head 4 , Laser controller 3.

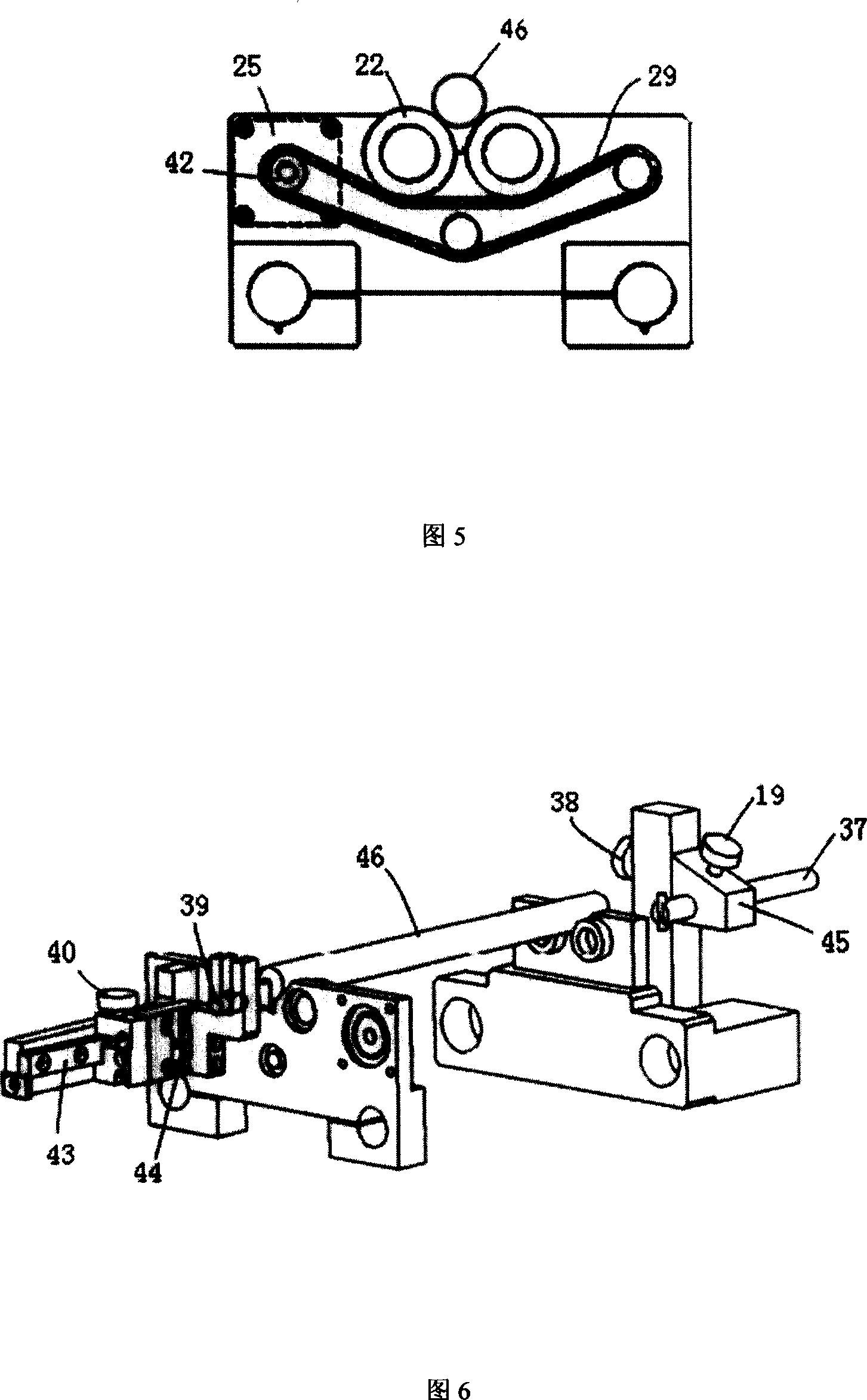

[0030] The horizontal moving device includes a servo motor 13 , a synchronous belt 11 , synchronous wheels 9 , 10 , slide rails 14 , sliders 15 , and a main sliding plate 16 .

[0031] The servo driver 33 is connected to the servo motor 13, and the servo motor 13 can rotate freely forward and reverse under the control of the servo driver 33. When the servo motor 13 is driven, the synchronous wheel 9 can be rotated, and the synchronous wheel instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com