Method for random error elimination in optical element interference sampling data

A technology of optical components and sampling data, applied in the direction of optical devices, optical instrument testing, machine/structural component testing, etc., can solve problems such as large errors, inability to provide accurate distribution of optical component surface errors, and ineffective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

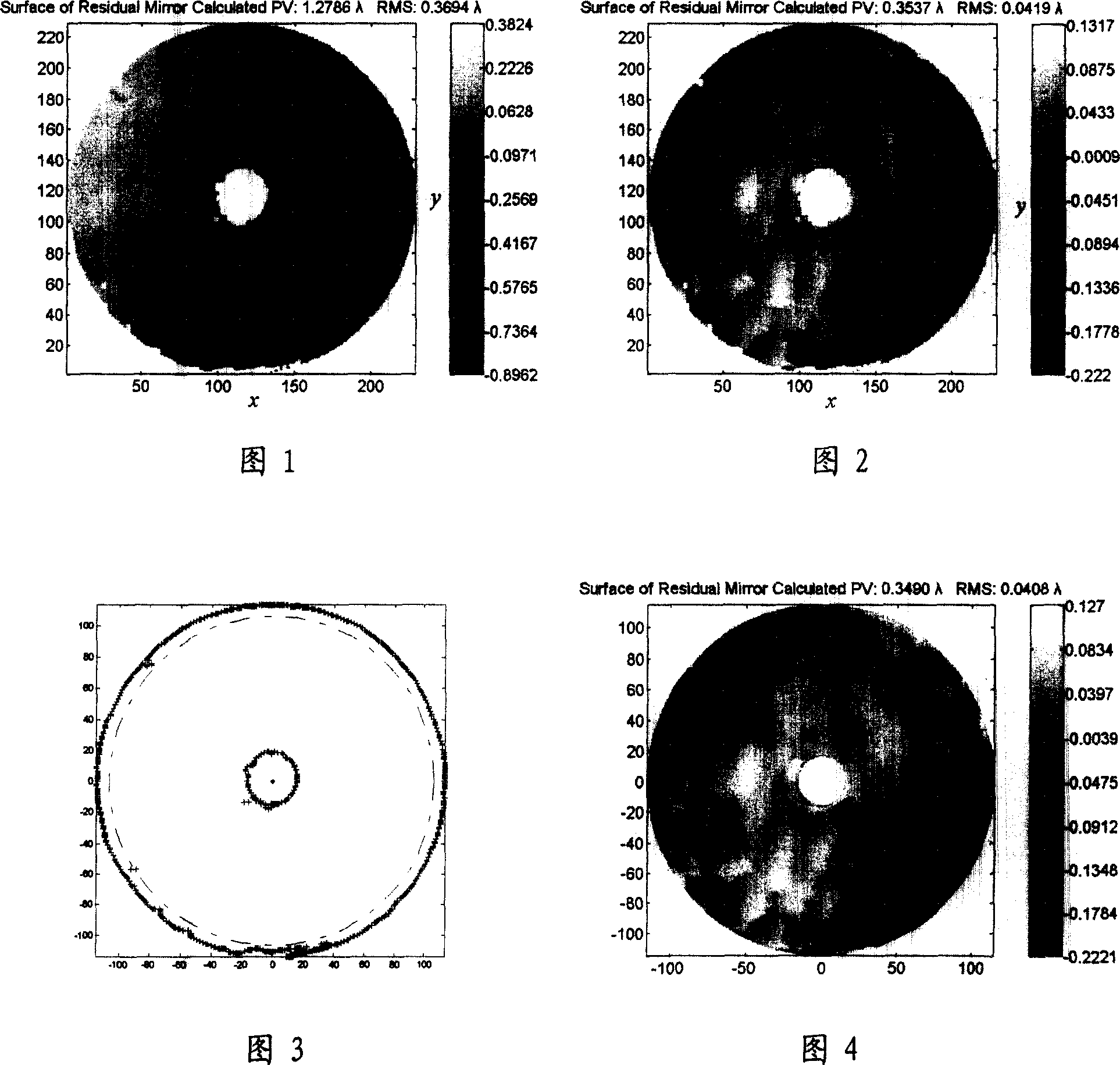

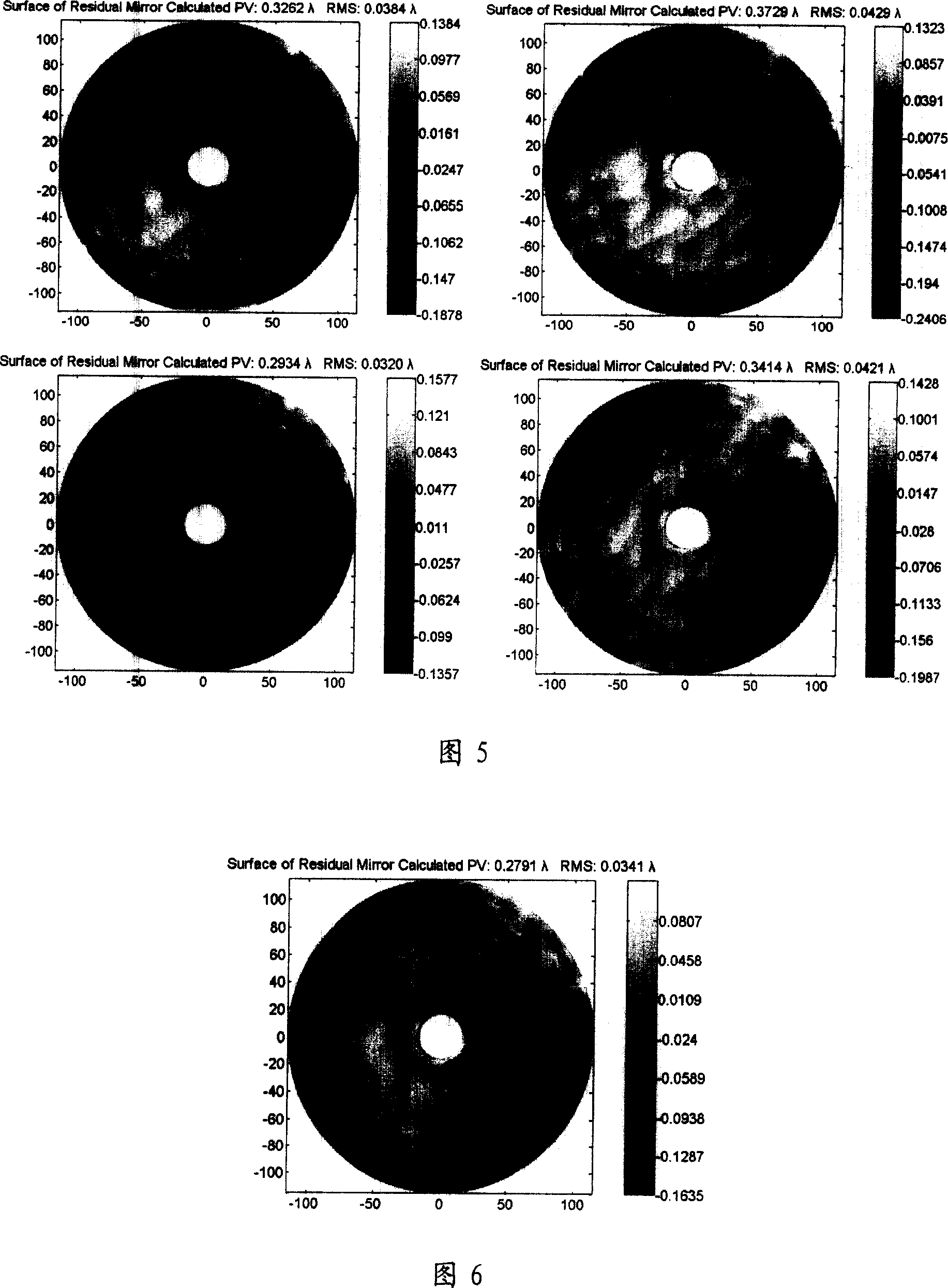

[0039] Embodiment 1, the analysis process of eliminating the random error in the optical element interference sampling data when detecting the aspherical mirror with a diameter of =1200mm by the method of the present invention:

[0040] ① Obtain the surface shape data of the inspected circular aperture optical element through the interferometer, use the length measurement tool to determine the measured range of the inspected optical element, and give the x and y directions in the interferogram, as shown in Figure 1. ;

[0041] ②Use the least square method to eliminate the tilt term and constant term from the surface data of the optical element;

[0042] The elimination of the oblique term and constant term of the surface shape data of the optical element can be linearly fitted to the measured data through the linear fitting function y=ax+b. According to the least square fitting method, the normal equation can be solved by:

[0043] ma ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com