Movable combination valve

A compound valve and movable connection technology, which is applied in the field of compound valves, can solve the problems of inaccurate ball seal positioning, difficult processing, and difficult control of welding quality, and achieve the effect of accurate ball seal position and simple machining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

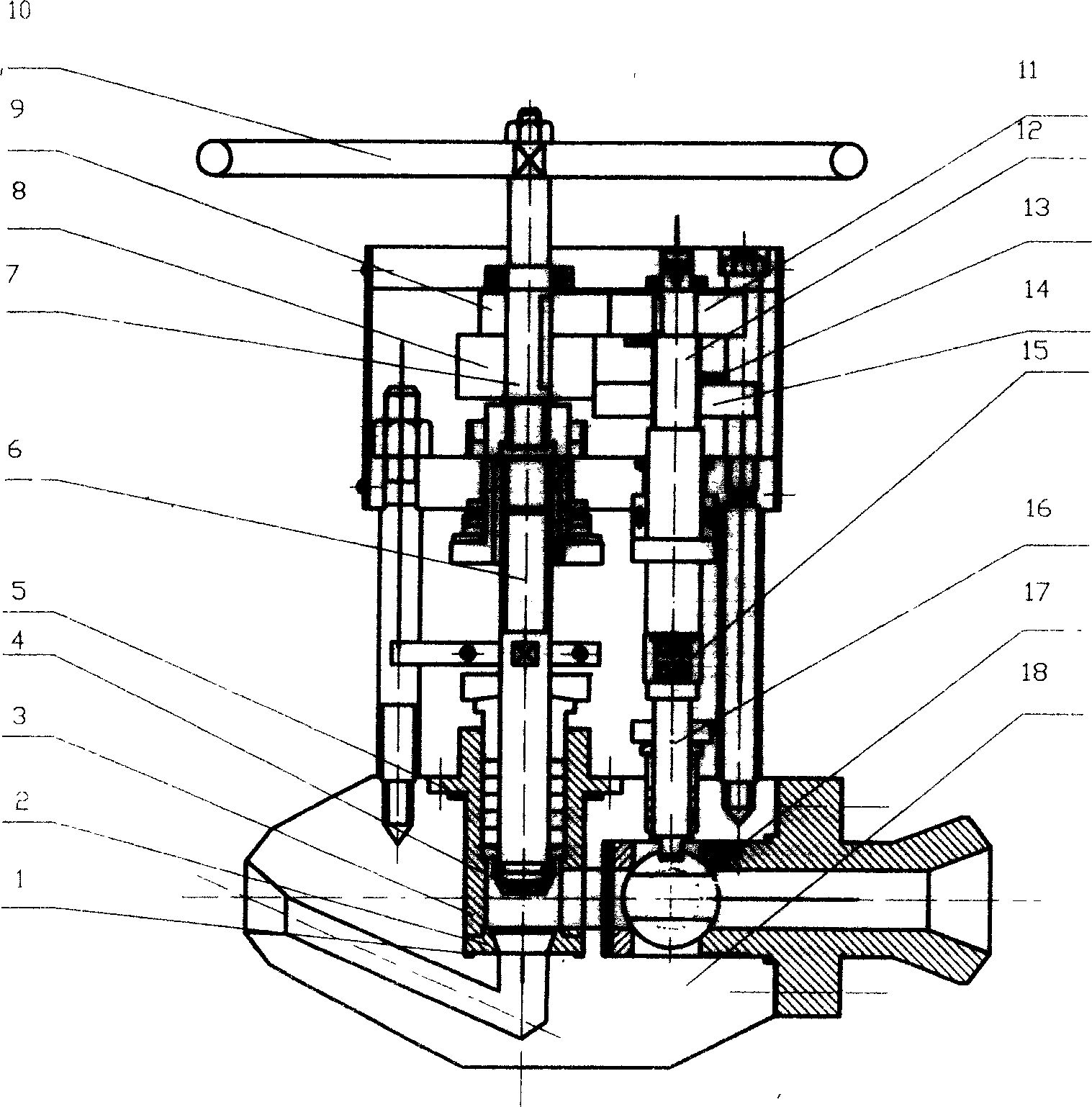

[0010] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0011] The technical scheme of the present invention is realized through the following approach, it is made up of globe valve and ball valve, and globe valve comprises valve body 18, valve seat 2, valve stem, cage 3, valve core 4, wherein cage 3 and valve seat 2 For movable connection, the valve seat 2 and the valve body 18 are also movable connected, the cage 3 is provided with a packing hole, the valve core 4 is a movable valve core; the valve stem is composed of a lower cut-off valve stem 6 and an upper cut-off valve stem 7, and There is a spline connection between the lower cut-off valve stem 6 and the upper cut-off valve stem 7; the upper cut-off valve stem 7 is fixed with a driving gear 8 and a driving cam 9, and the driving cam 9 is located above the driving gear 8;

[0012] The ball valve includes a sphere 17, a lower ball valve st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com