Centrifugal compressor having vane jet orifice

A centrifugal compressor and compressor technology, which is applied to the components of pumping devices for elastic fluids, mechanical equipment, machines/engines, etc., and can solve problems such as large flow loss, stall, surge, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

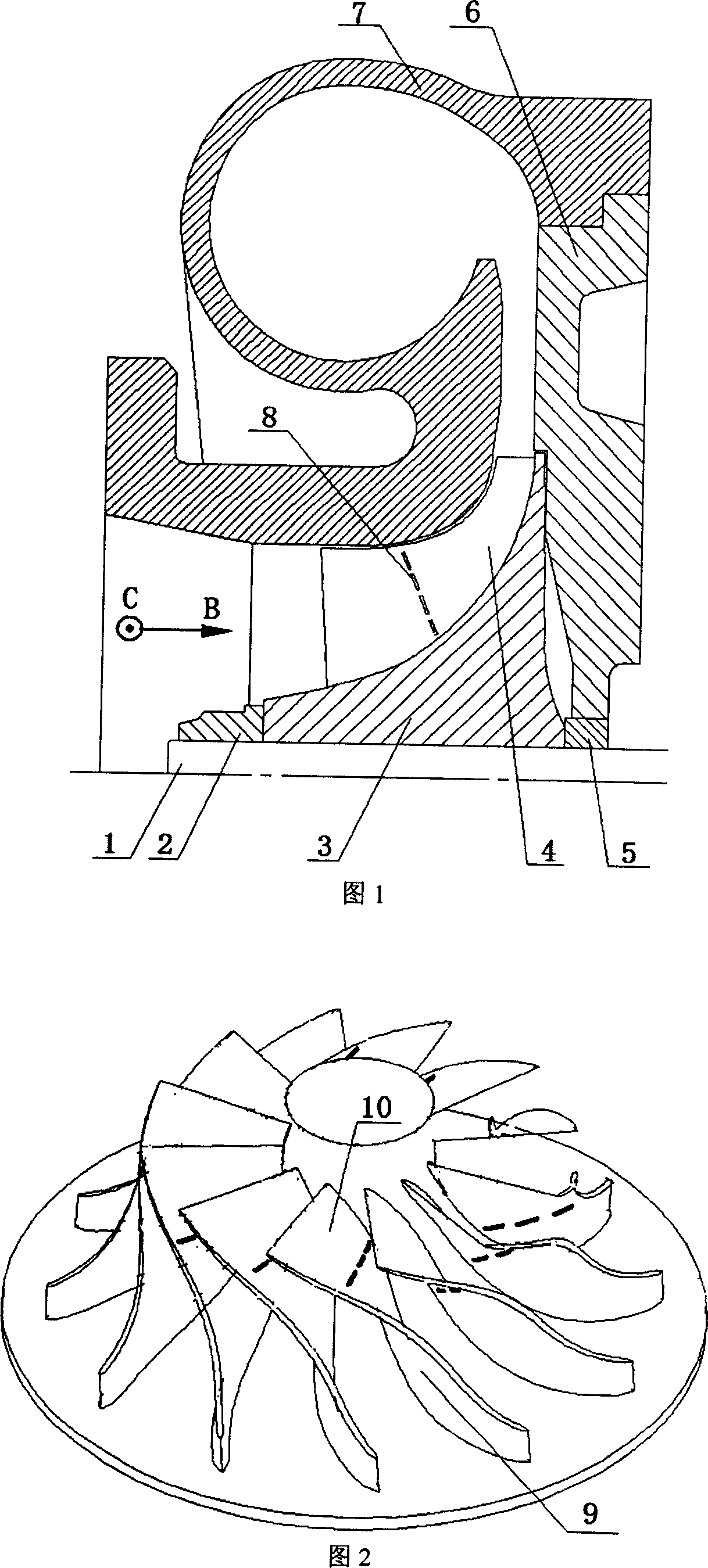

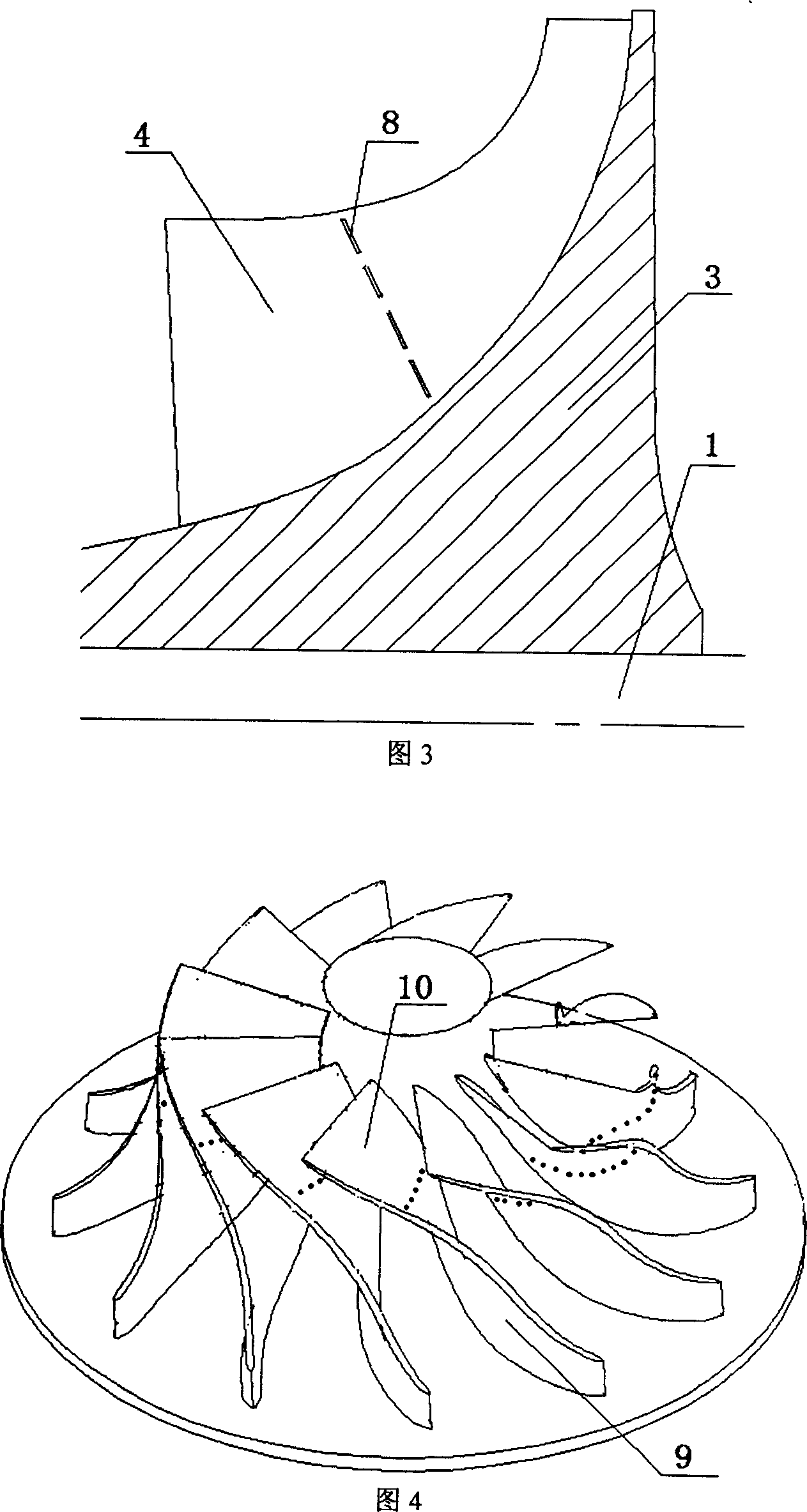

[0016] The specific embodiment of the present invention will be described with reference to the accompanying drawings.

[0017] As shown in Fig. 1, the compressor rotating shaft 1, the impeller fixing bolt 2, the impeller 3, the blade 4, the seal block 5, the impeller back plate 6, and the volute 7 are common parts of the existing compressor. The present invention is characterized in that the blade 4 has the largest curvature along the mainstream direction, and a jet port 8 is opened along the blade height direction. During operation, under the action of the pressure difference between the two sides of the blade, a small stream of gas is sprayed from the pressure surface through the jet port 8 and from the suction surface. out. The jet port 8 can be one or more slits or a plurality of through holes, and Fig. 1 shows the situation of a plurality of slits. Where C represents the direction of rotation of the compressor impeller, and B represents the direction of inlet airflow. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com