Centrifugal compressor having air removal jet box structure

A centrifugal compressor and compressor technology, which is applied to machines/engines, components of pumping devices for elastic fluids, mechanical equipment, etc., can solve problems such as stall flow loss, unstable compressor operation, large flow loss, etc. , to achieve the effect of suppressing flow separation, improving stall margin and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

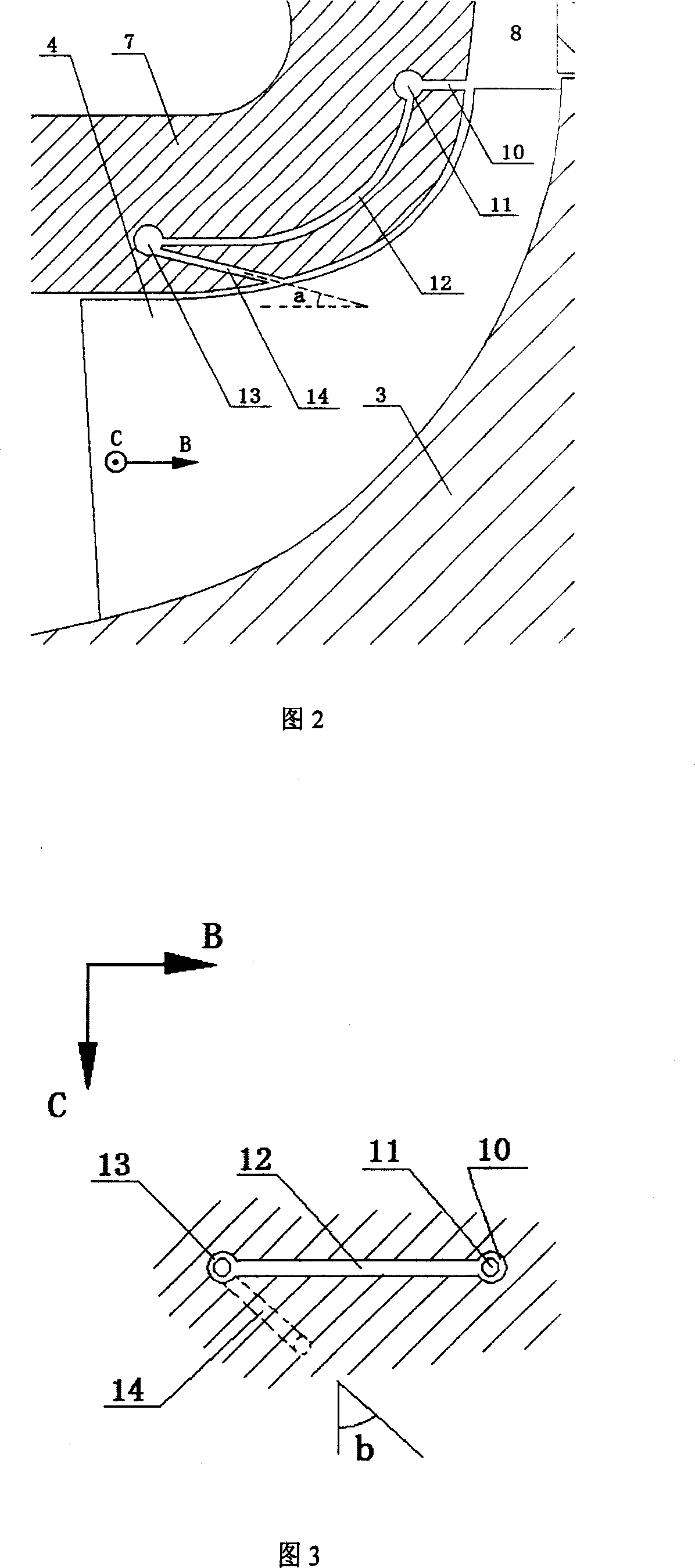

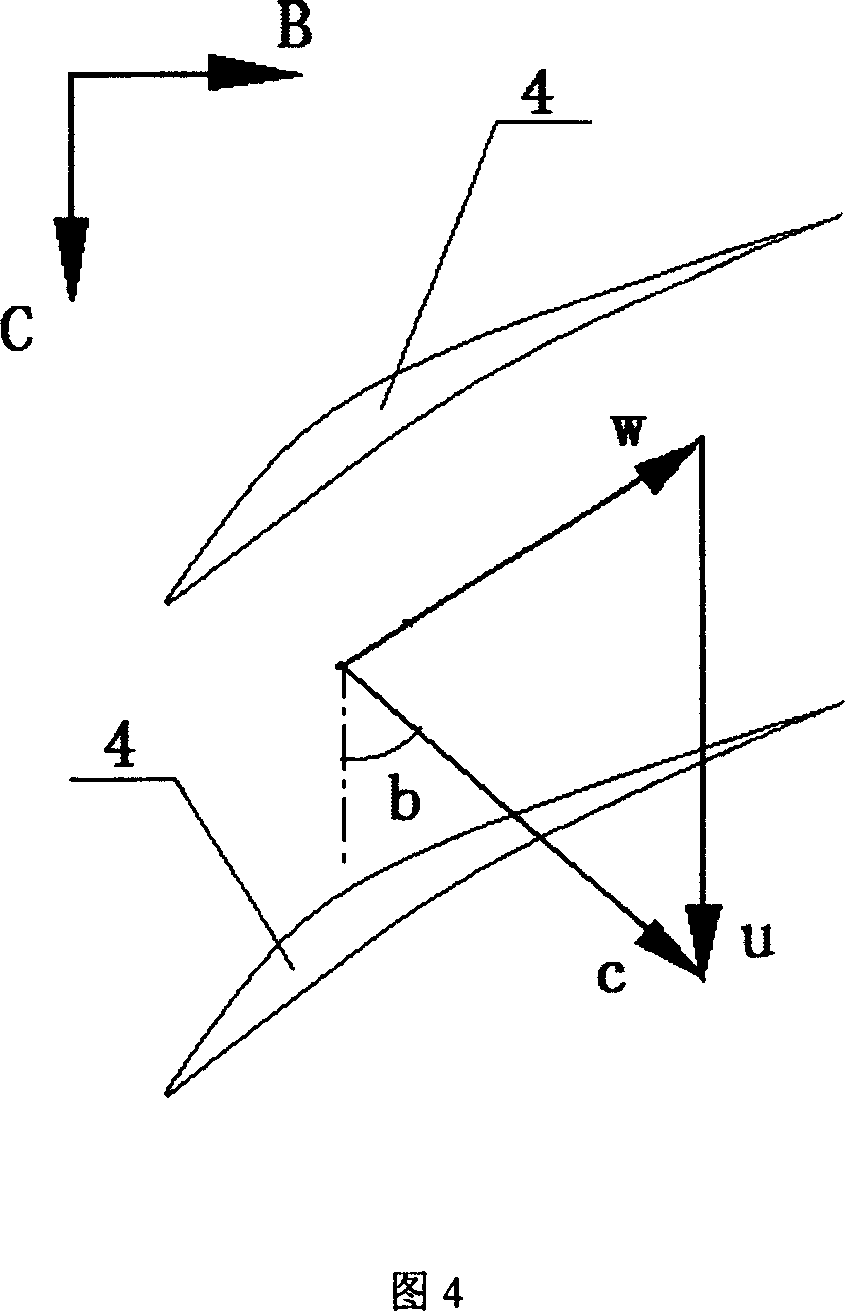

[0015] The specific embodiment of the present invention will be described with reference to the accompanying drawings.

[0016] As shown in Figure 1, compressor shaft 1, impeller fixing bolts 2, impeller 3, blade 4 on impeller 3, sealing block 5, impeller back plate 6, volute 7, all are common parts of existing compressors, without blades The diffuser channel 8 is formed by the combination of the impeller back plate 6 and the volute 7 . The inlet flow direction is B, and the compressor impeller 4 rotation direction is C. The present invention is characterized in that no less than three air extraction-jet flow guide passages 9 are opened on the casing wall of the volute 7, and each air extraction-jet flow guide passage 9 is uniformly distributed around the compressor shaft 1 as the center. , the suction hole at the back end of the diversion channel is opened at the casing wall of the inlet of the vaneless diffuser 8, the jet hole at the front end is opened at the maximum twist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com