Recording device and method for hoisting machinery operating state

A technology of operating status and hoisting machinery, which is applied in the field of operation monitoring and accident records of large-scale hoisting machinery, and can solve problems such as the inability to prevent and avoid accidents, and the inability to monitor the operating status of hoisting machinery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

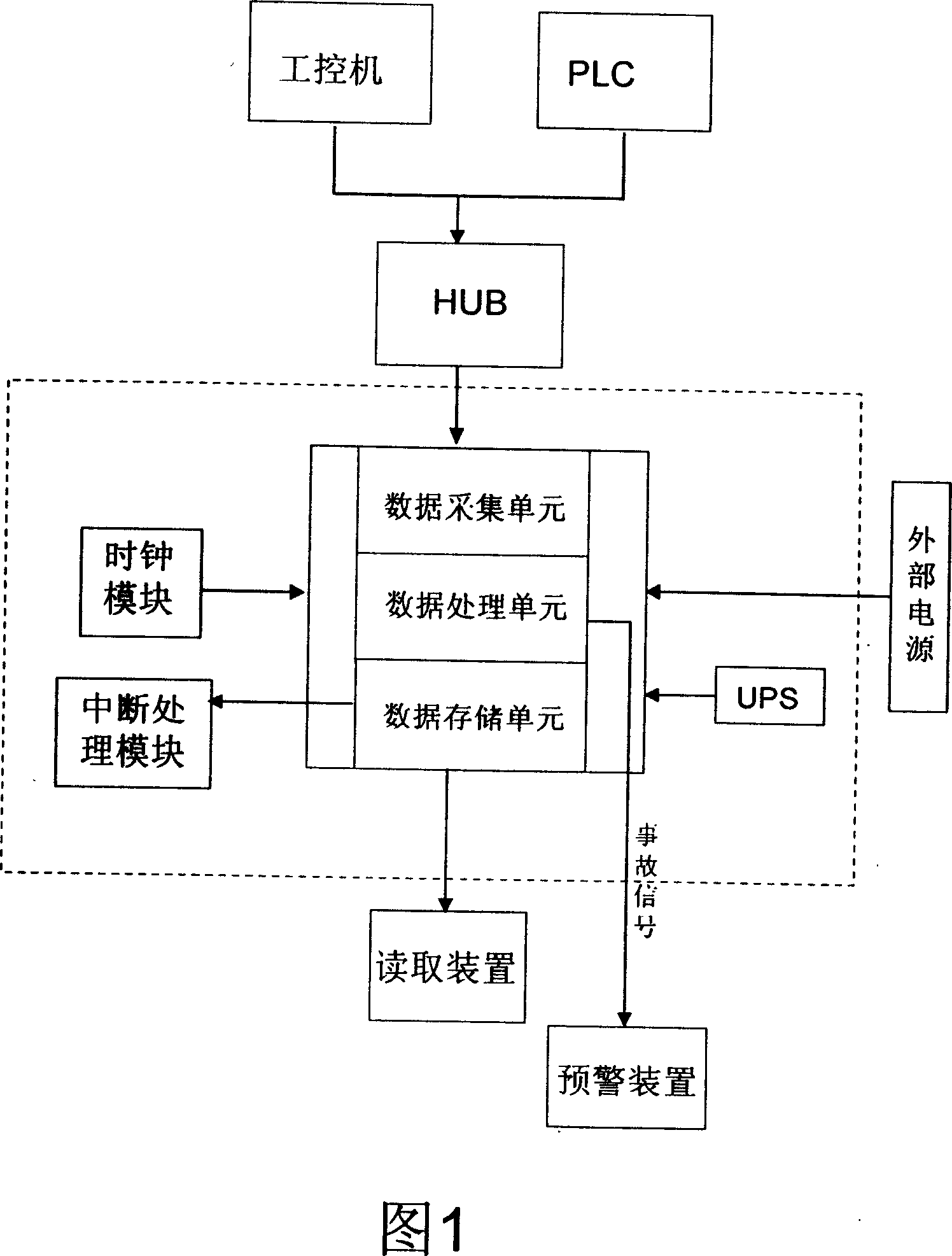

[0036] Please refer to shown in Fig. 1, the recording device of hoisting machine running state of the present invention is arranged in a sealed box body, and this box body has the performance of high temperature resistance, high pressure resistance, corrosion resistance, and is powered by external power supply, comprises:

[0037] The data acquisition unit is externally connected to the industrial computer and the programmable logic controller (PLC) installed on the hoisting machinery through the network hub (HUB), and collects the operation of the hoisting machinery through the industrial computer and the programmable logic controller (PLC). The signal is converted into a data signal. The collected signal includes the wind speed signal, the motor signal (including the current, voltage, and speed of the motor) of the main mechanism of the hoisting machinery such as walking, lifting, turning, and luffing, the driver, the brake, and the important limit. More than 120 important pa...

Embodiment 2

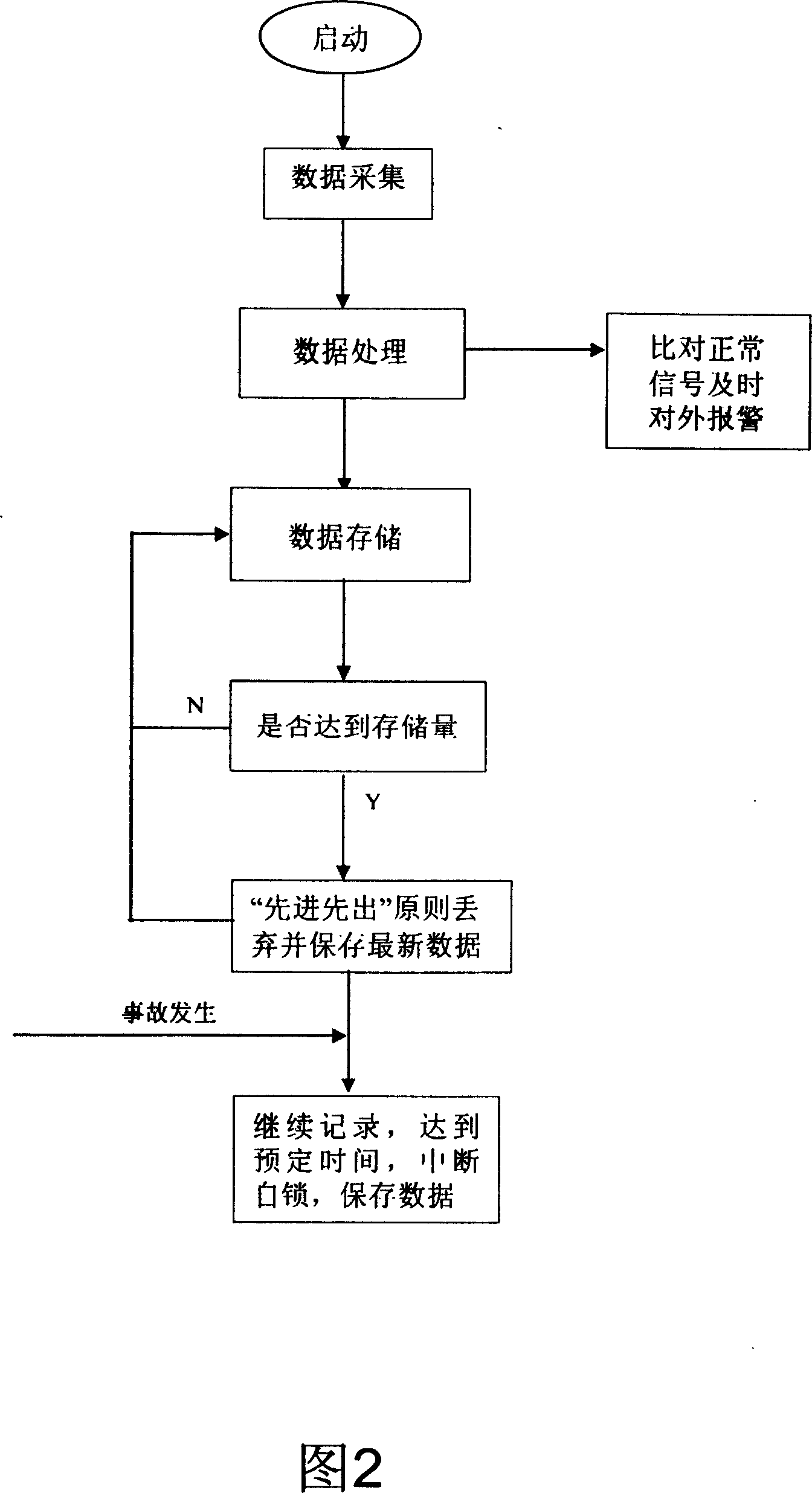

[0041] See also shown in Fig. 2, the specific steps of the method for recording hoisting machine running state of the present invention are:

[0042] Start the recording device first, use the data acquisition unit of the device to collect the operating status signal of the hoisting machinery, and convert it into a data signal, and the data acquisition unit communicates with the industrial computer installed on the hoisting machinery through the network hub (HUB) respectively. It is connected with the programmable logic controller (PLC), and collects the operation signal of the hoisting machinery through the industrial computer and the programmable logic controller (PLC) and converts it into a data signal. The collected signal includes the wind speed signal, the walking and lifting of the hoisting machinery The signal of the motor (including the current, voltage, and speed of the motor) of the main mechanism such as , slewing, and luffing, more than 120 important parameter signa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com