Fine granule material friction electrical selection method and device

A triboelectric separation and fine particle technology, applied in chemical instruments and methods, electrostatic separation, electrostatic effect separation, etc., can solve the problems of environmental pollution, fixed investment and high operating costs, and reduce environmental pollution, fixed investment and operating costs. Low, the effect of improving boiler efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

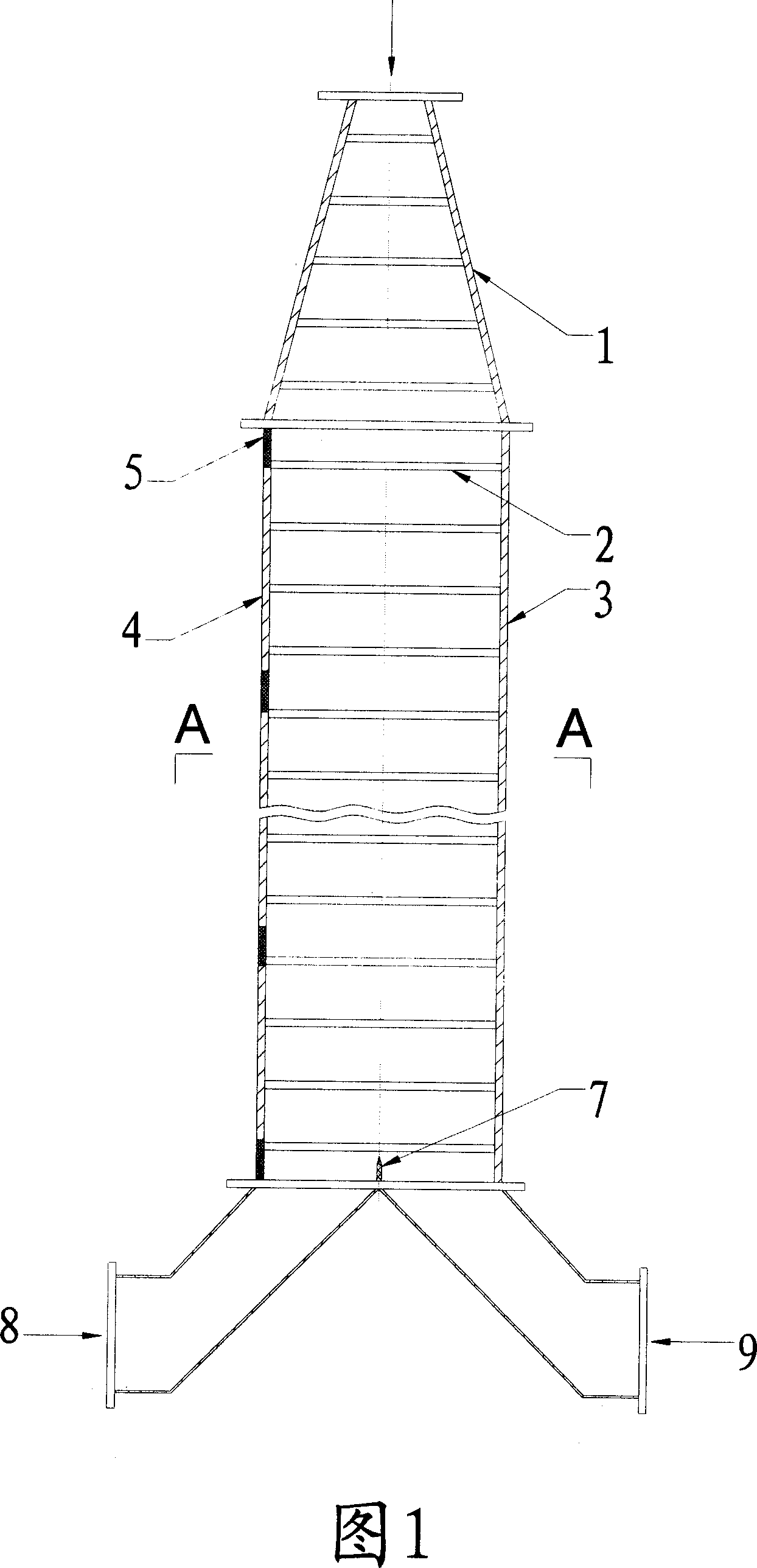

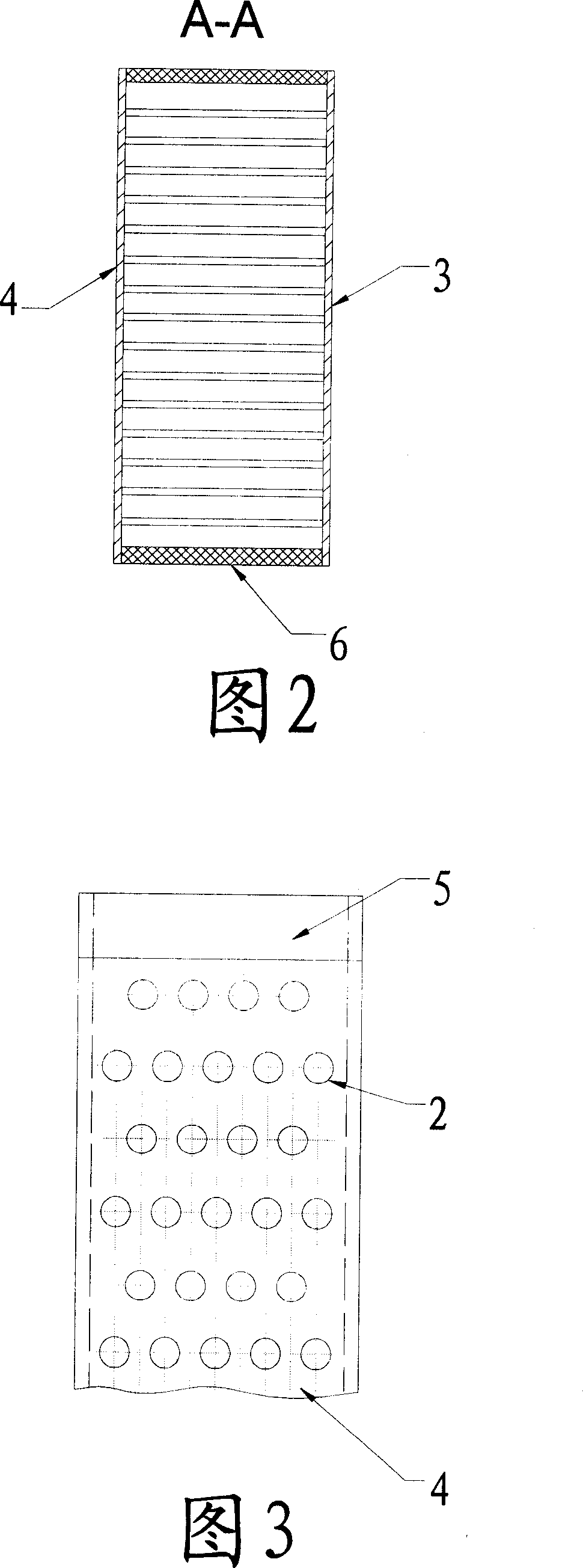

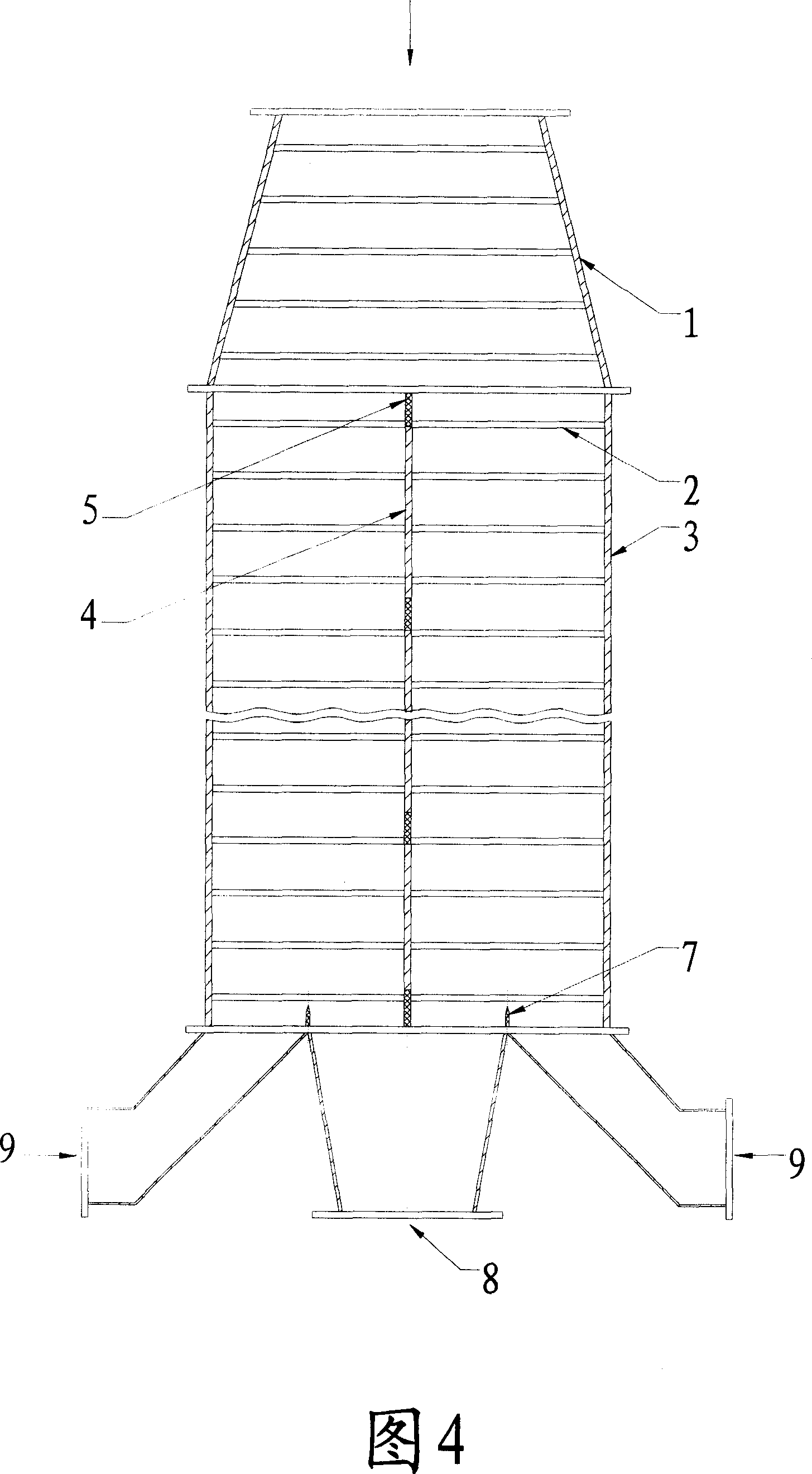

[0012] The triboelectric separation method for micro-grained materials of the present invention adopts the method of transporting the materials to be separated that are ground to a certain particle size by gas. When the substance collides with the friction rod and the wall or the substances of different components collide with each other, it is charged with the opposite polarity. At the same time, the charged powdery material group passes through the high-voltage DC When the power supply forms a high-voltage electrostatic field between the electrode plate and the ground electrode, the particles with opposite polarity charges are subjected to the electric field force in the opposite direction, thereby shifting to the opposite polarity plate, and are divided by the partition plate to form two strands The material flow composed of different component mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com