Tea cigarette and its manufacturing method

A technology for tea and cigarettes, applied in the field of cigarettes, can solve the problems of high technical level, reduced planting area, and no fragrance and health, and achieve the effects of increasing planting area, increasing grain output, and reducing planting area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

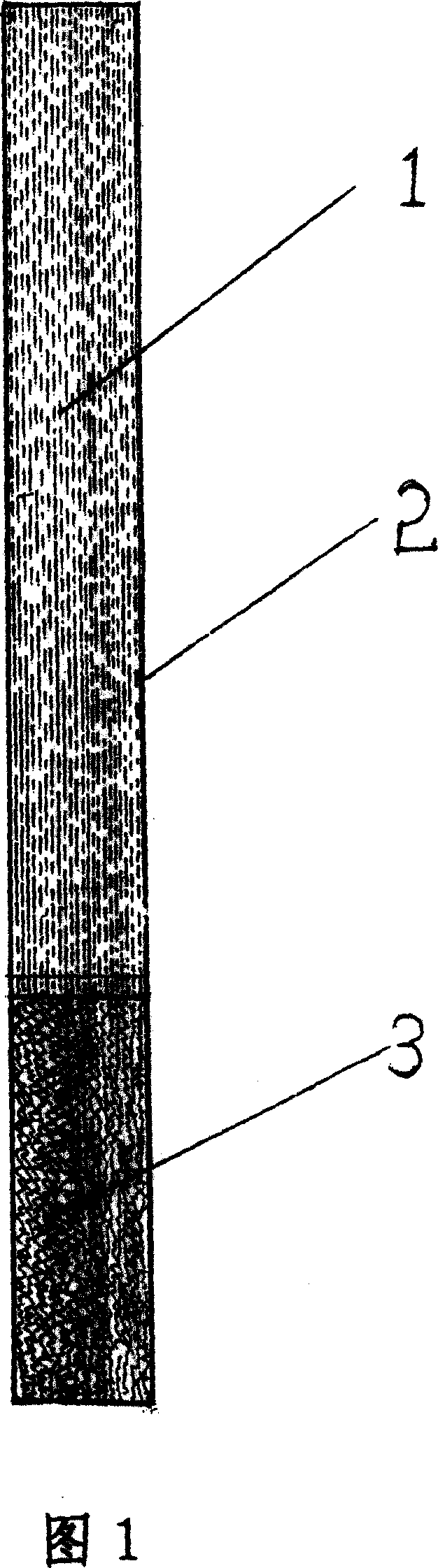

[0023] Tea cigarettes are shown in Figure 1. Tea cigarettes consist of three parts: 1 tea shreds; 2 cigarette paper; 3 filters. The shredded tea tobacco 1 is a small strip of tea shreds with a width of 1.2 mm to 1.5 mm and a length of 2 mm to 20 mm. The cigarette paper 2 and the filter tip 3 are the same as those in existing cigarettes.

[0024] The concrete making method of tea cigarette is as follows:

[0025] ①. Select fresh tea leaves, remove miscellaneous leaves, remove tea stems, and then dry the tea leaves. The choice of fresh tea leaves is generally selected in pure natural and pollution-free organic tea gardens in alpine mountainous areas. Fresh leaves with large and fat leaves are picked in spring, summer and autumn. The general growth period is about 15 days. The larger the leaves, the longer the photosynthesis time, the more chlorophyll produced by fresh leaves, and the higher the nutritional content of vitamins, amino acids and minerals contained in them. Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com