Heat-proof magnesium-base rare earth alloy and its preparation method

A rare-earth alloy and heat-resistant technology, which is applied in the field of heat-resistant magnesium-based alloys and their preparation, can solve the problems of limited varieties of heat-resistant magnesium-based rare-earth alloys, unsatisfactory performance/price ratio, and inefficient utilization of rare-earth resources. Excellent comprehensive performance, the effect of reducing the cost of the alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

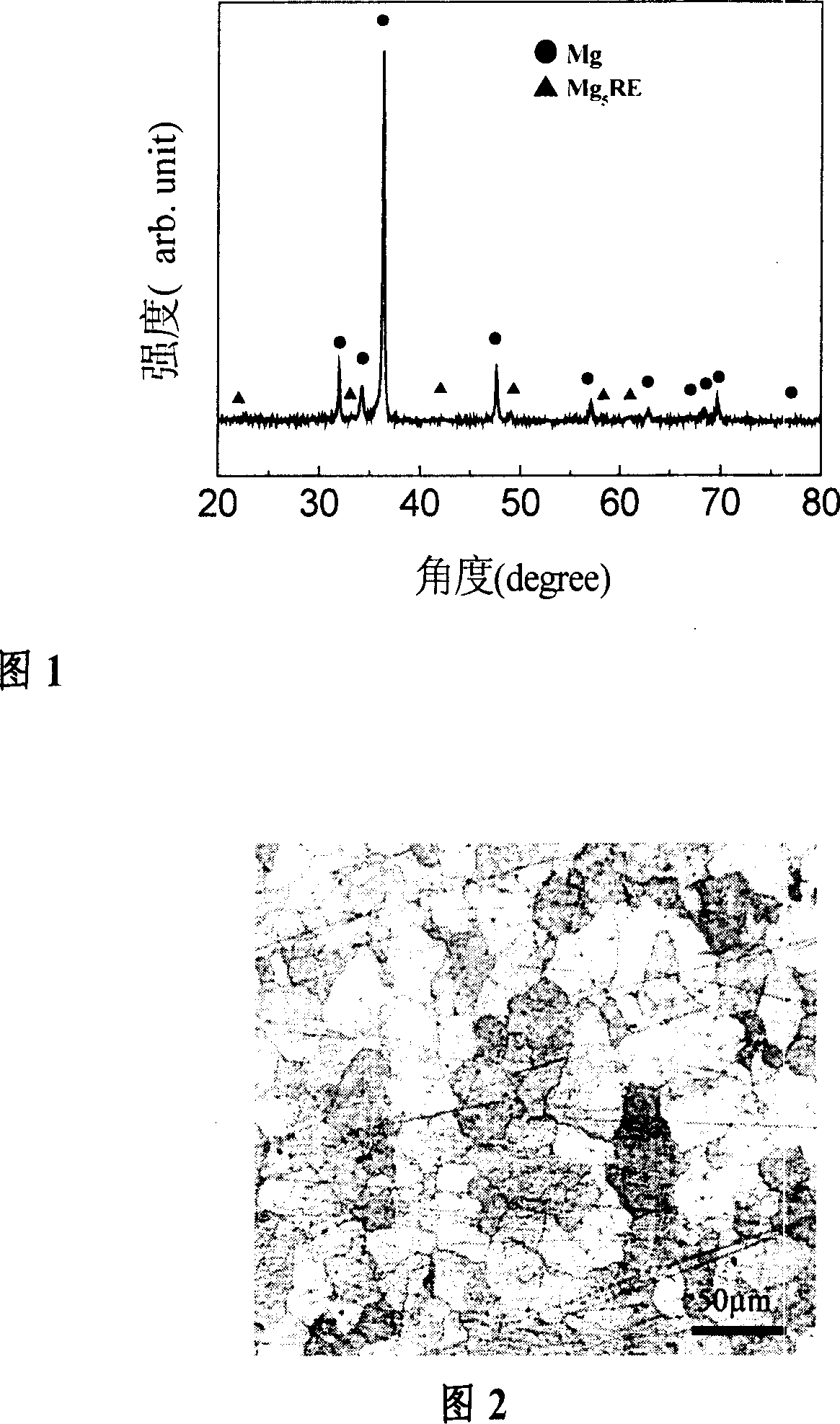

Embodiment 1

[0037] Raw material proportioning is carried out according to the composition of Mg-6%Gd-3%Dy-0.5%Zr, wherein the percentages are weight percentages, and Mg is the balance. The raw materials used in this formula are commercially available Mg ingots with a purity of 99.9%, 99.5% Mg-20%Gd and Mg-25%Dy master alloy ingots, and 99.5% Mg-30%Zr master alloy ingots. After metal ingots and alloy ingots are cut, degreased, dried and descaled, the degreasing method is mainly to soak the metal and alloy raw materials in lye containing surfactants for scrubbing and then rinse with clean water; drying is natural Drying; the method of descaling is mechanical removal by filing or planing.

[0038] Counterweight according to the designed content. The weighted metal block and alloy block are dipped in molten salt in the molten salt pool and then added to the melting temperature T f In the melting furnace at 780°C, the order of adding raw materials is: metal Mg, Mg-20%Gd, Mg-25%Dy and Mg-30%Z...

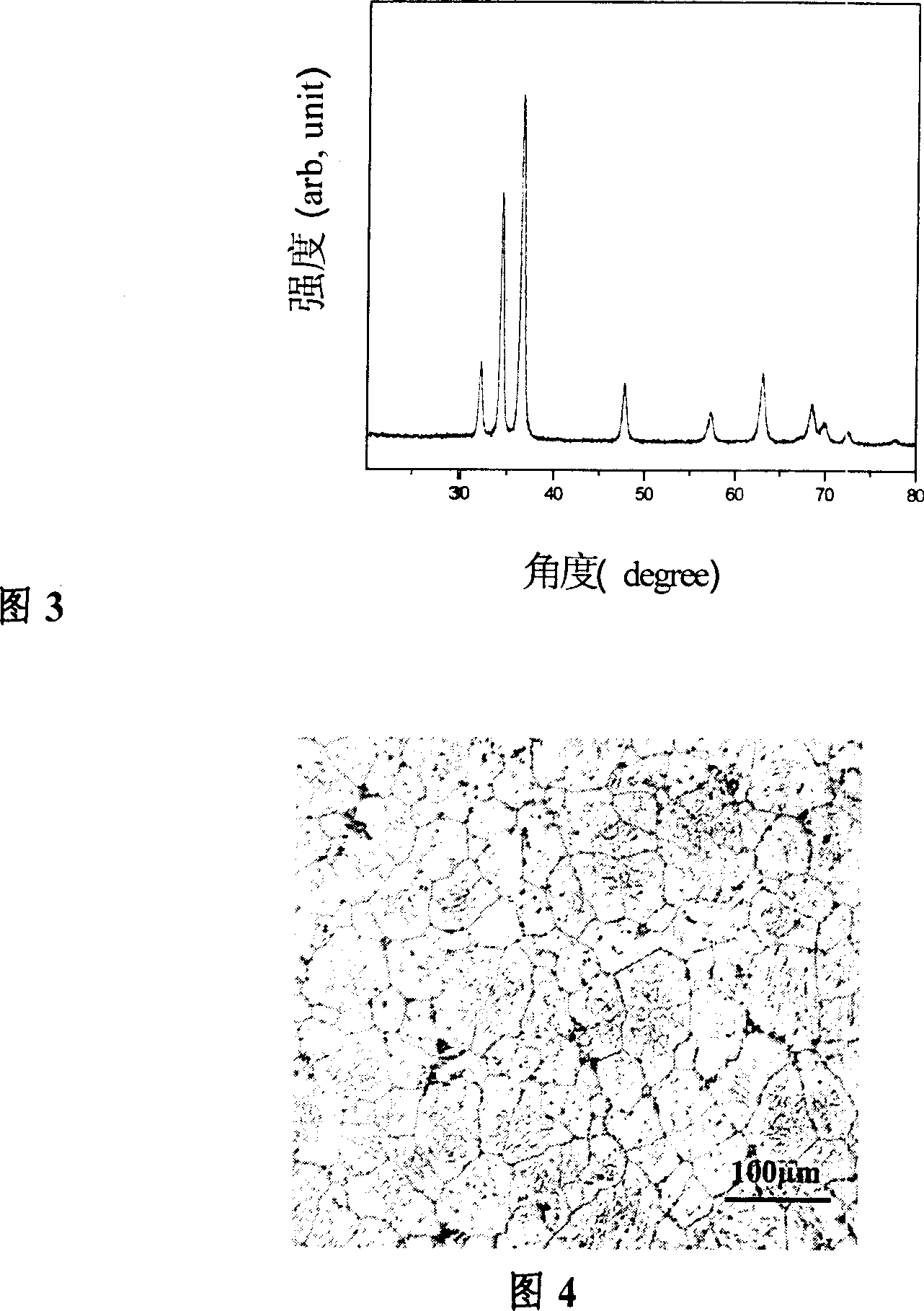

Embodiment 2

[0048] All the other are with embodiment 1. The composition of the heat-resistant magnesium alloy is Mg-8%Gd-1%Dy-0.5%Zr. Its preparation process parameter is: T f is 650℃, ts is 2min, t p 10min, T w at 200°C, T p at 670°C, T wg at 60°C, T at at 200°C, t at for 50h.

[0049] The mechanical properties of the as-cast Mg-8%Gd-1%Dy-0.5%Zr heat-resistant magnesium alloy of the present invention are:

[0050] Room temperature: tensile strength: 202MPa; yield strength: 113MPa; elongation: 7.8%.

[0051] 250°C: tensile strength: 179MPa; yield strength: 107MPa; elongation: 11%.

[0052] The mechanical properties of the Mg-8%Gd-1%Dy-0.5%Zr heat-resistant magnesium alloy of the present invention after heat treatment are:

[0053] Room temperature: tensile strength: 367MPa; yield strength: 270MPa; elongation: 6.7%.

[0054] 250°C: tensile strength: 290MPa; yield strength: 215MPa; elongation: 8.9%.

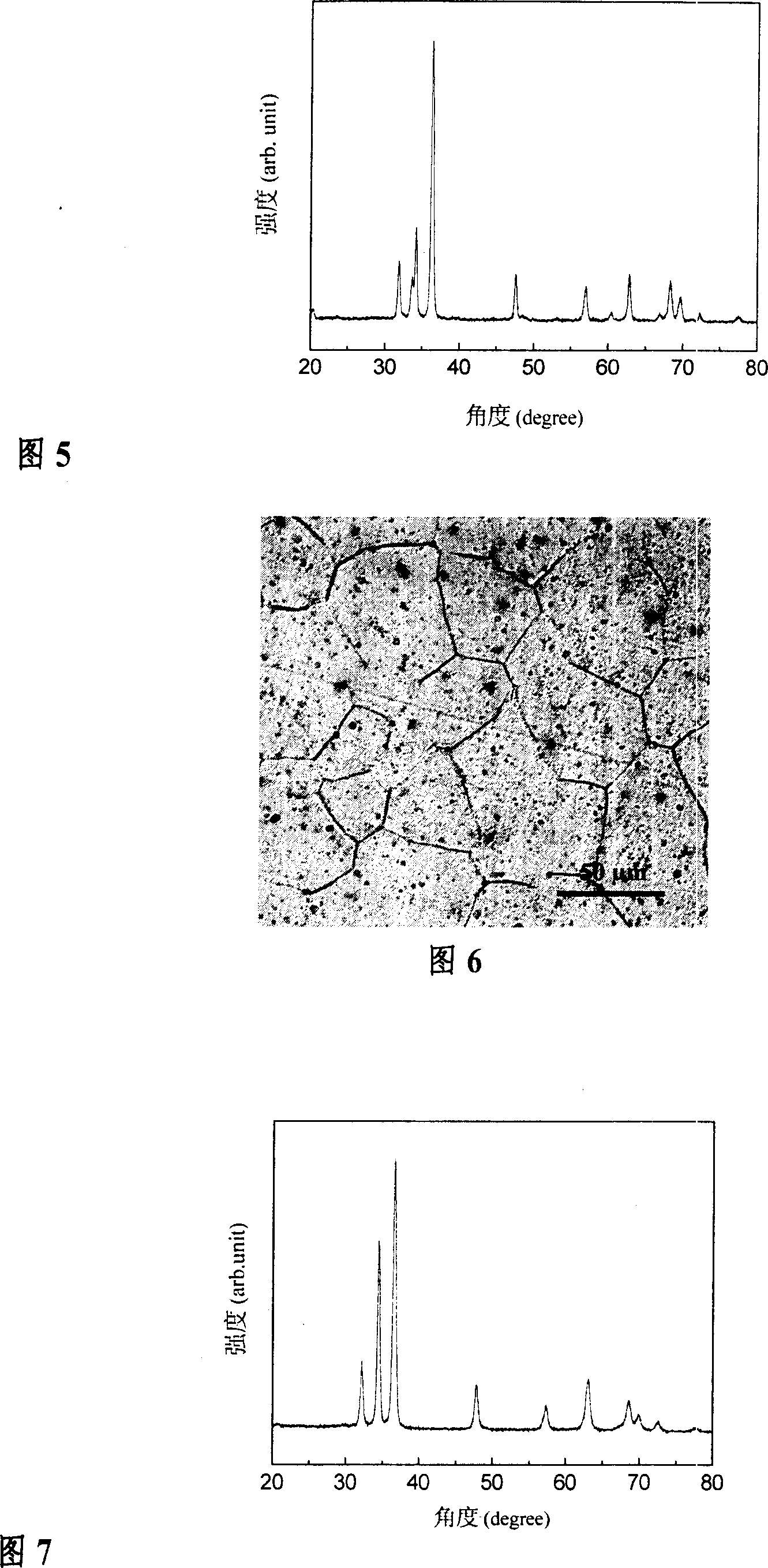

Embodiment 3

[0056] All the other are with embodiment 1. The composition of the heat-resistant magnesium alloy is Mg-7%Gd-5%Dy-0.4%Zr. Its preparation process parameter is: T f is 715℃, ts is 6min, t p 15min, T w 210°C, T p 690°C, T wg at 60°C, T at at 230°C, t at It is 72h.

[0057] The mechanical properties of the as-cast Mg-7%Gd-5%Dy-0.4%Zr heat-resistant magnesium alloy of the present invention are:

[0058] Room temperature: tensile strength: 242MPa; yield strength: 123MPa; elongation: 7.1%.

[0059] 250°C: tensile strength: 199MPa; yield strength: 128MPa; elongation: 9.4%.

[0060] The mechanical properties of the Mg-7%Gd-5%Dy-0.4%Zr heat-resistant magnesium alloy of the present invention after heat treatment are:

[0061] Room temperature: tensile strength: 379MPa; yield strength: 275MPa; elongation: 7.7%.

[0062]250°C: tensile strength: 298MPa; yield strength: 235MPa; elongation: 9.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com