Lead-free phosphate sealed glass for electrothermal tube and its preparation method

A lead-free phosphate, sealing glass technology, applied in the chemical industry, to achieve the effect of green environmental protection, low softening point and high cost performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

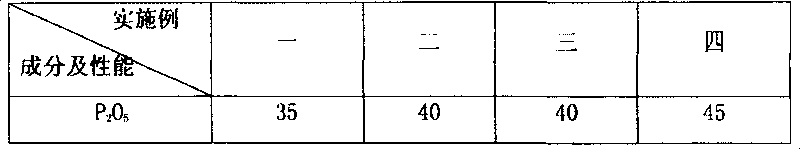

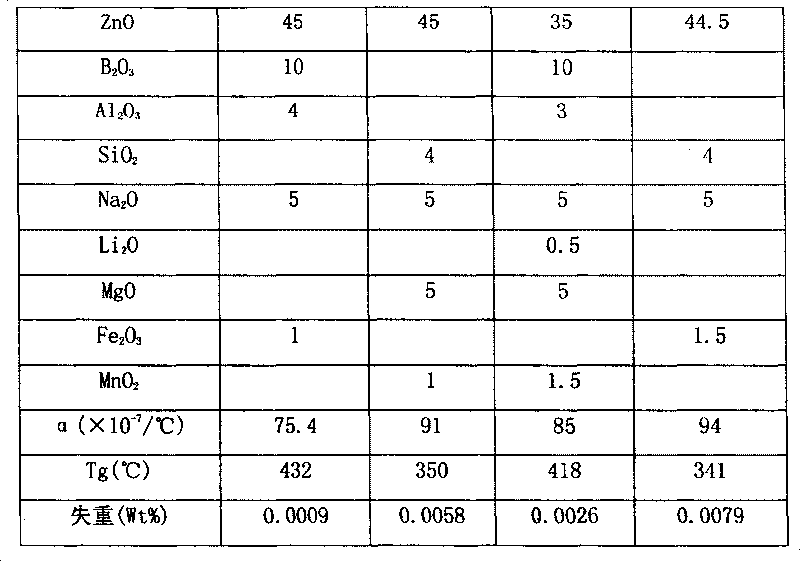

[0028] Table 1 (mol%)

[0029]

[0030]

[0031] The preparation methods of the four lead-free sealing glasses listed in the above Table 1 are the same.

[0032] Weight loss was measured after constant temperature in deionized water at 90°C for 9 hours.

[0033] Weigh each component according to the molar percentage of the raw materials in Table 1, then mix the raw materials evenly, keep the mixture at 200-250°C for 1-3 hours, and then melt the mixture at 1050-1250°C for 0.5 ~ 2 hours, and finally the molten glass is molded into columns and powders.

[0034] In Table 1, P 2 o 5 , ZnO is the basic component of glass, Na 2 O. Li 2 O can increase the expansion coefficient of glass, Al 2 o 3 , SiO 2 Can reduce the expansion coefficient of glass and improve the chemical stability of glass, MgO, Fe 2 o 3 , MnO 2 Can improve the chemical stability of glass. By adding different components and adjusting the proportion relationship between the components, the expansion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transition temperature | aaaaa | aaaaa |

| sealing temperature | aaaaa | aaaaa |

| sealing temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com