Method for forming sulfidization pattern on rubber product surface

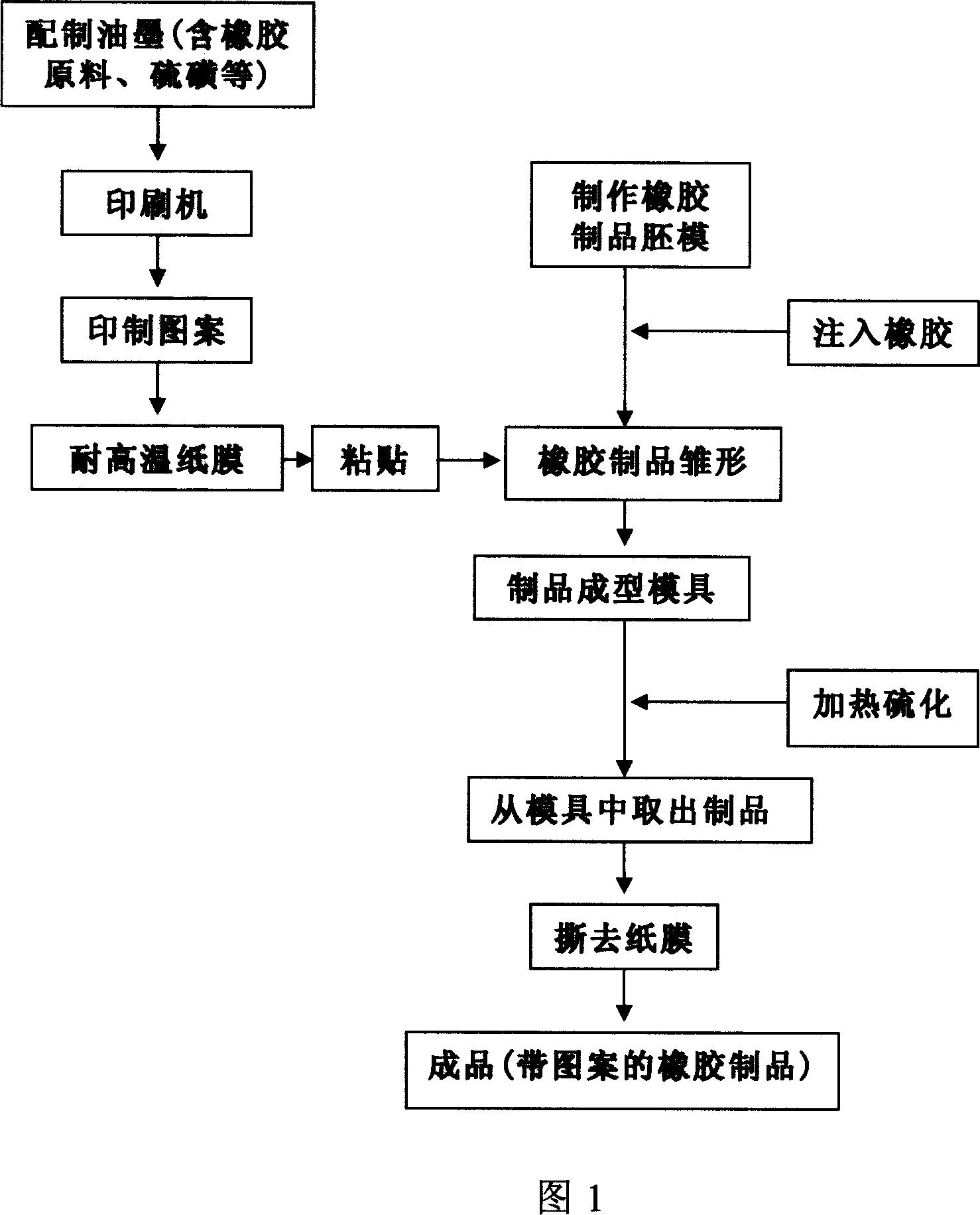

A technology for rubber products and patterns, applied in the field of rubber products, can solve problems such as inability to extrude products, flow of pattern pigments, and easy adhesion of ink and pigments, and achieve the effects of high degree of mechanization, saving mold costs, and reducing fluidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: vulcanized pattern on the surface of rubber sole

[0027]Inks were formulated with different formulations containing rubber raw material and sulfur (1%, 3%, 5%, 8%, 10% or 15%). Print inks with different ratios on the high temperature resistant paper film with the same pattern, and let it dry in time. In addition, the rubber material of the same rubber sole is prepared, and it is injected into the embryo film of the rubber sole of the same shape to make the prototype of the rubber sole. Paste the printed paper film on the same position of the prototype of the rubber sole, make rubber sole molding molds with a ratio of 1:1, 1:1.1, and 1:1.2 (prototype:mold) respectively, and paste the rubber sole with the patterned paper film The prototype is placed in a forming mold and vulcanized at 100°C, 120°C, 140°C, 160°C, 180°C and 200°C for 0.5min, 1min, 3min, 6min, 10min and 15min respectively, the mold is opened, the paper film is torn off, and the belt is obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com