Radial grading desulfurization dust-removing device

A technology for desulfurization and dust removal, desulfurization area, applied in the direction of separation method, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as low efficiency, equipment corrosion, serious scaling, etc., to reduce initial investment and operating costs, improve System reliability, effect of ensuring dust removal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

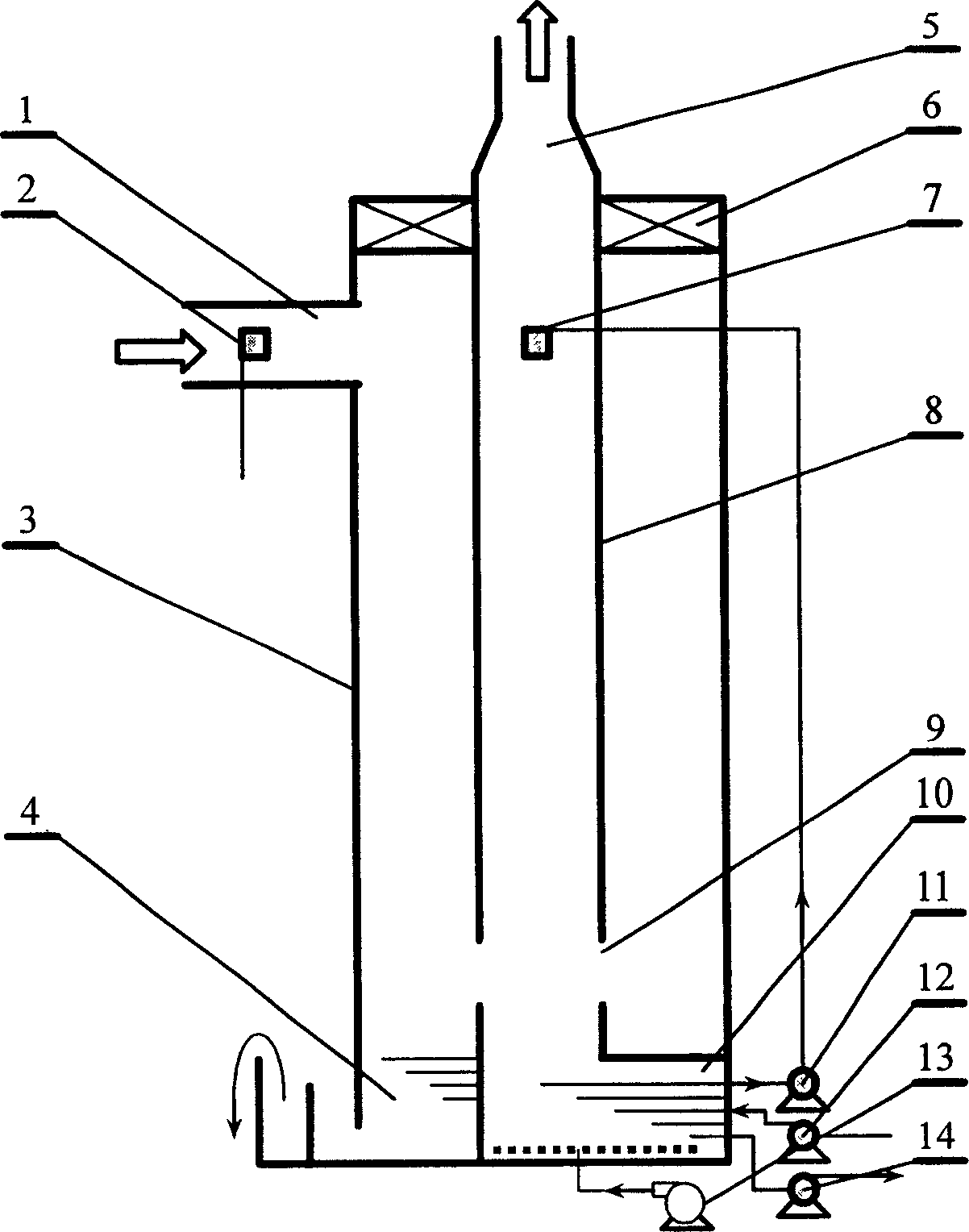

[0013] Provide a best embodiment of the present invention below in conjunction with accompanying drawing 1.

[0014] The process flow of the radial graded desulfurization and dust removal device is shown in Figure 1. The flue gas discharged from the boiler is pre-cooled by the ultra-fine atomized water sprayed by the water nozzle 2 in the inlet flue 1 before entering the dust removal and desulfurization tower, and the dust in the flue gas is agglomerated under the action of mist droplets to form large dust Granules to enhance the removal of dust. The pre-cooled flue gas enters the reactor outer cylinder 3 tangentially from the upper part of the reactor outer cylinder 3 . The outer annular area formed by the reactor outer cylinder 3 and the reactor inner cylinder 8 is a dust removal area. In the dust removal area, the flue gas rotates and flows downward. Under the action of centrifugal force, the smoke carried by the flue gas is captured by the liquid film on the inner wall o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com