Process for producing collagen sponge, process for producing artificial skin, artificial skin and cell tissue culture substrate

A technology of collagen sponge and manufacturing method, which is applied in the fields of skin transplantation, medical science, prosthesis, etc., can solve the problems of water-permeable adjustment layer wrinkles, lower pass rate, complex process, etc., and achieve the goals of promoting healing, excellent performance, and simplifying the process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

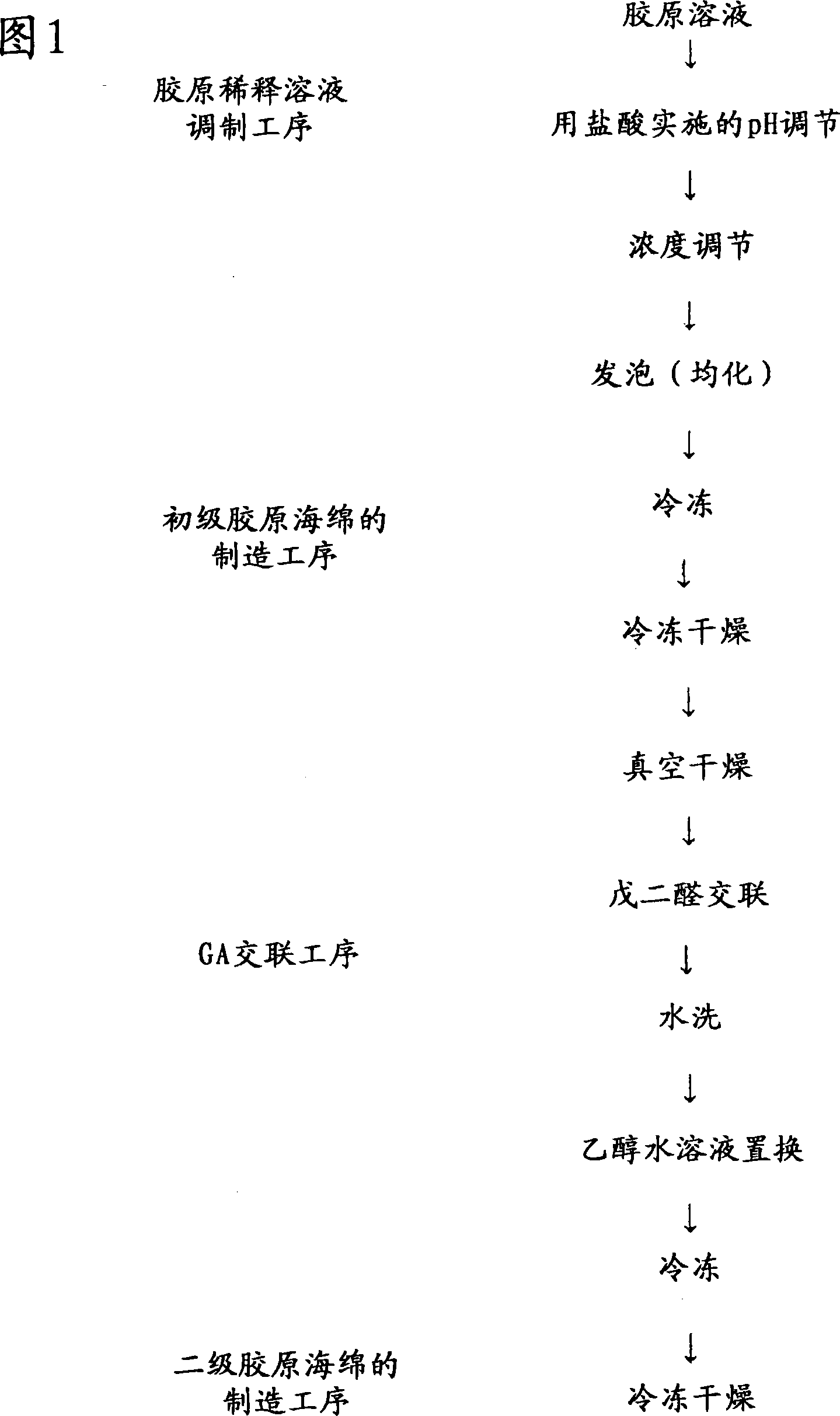

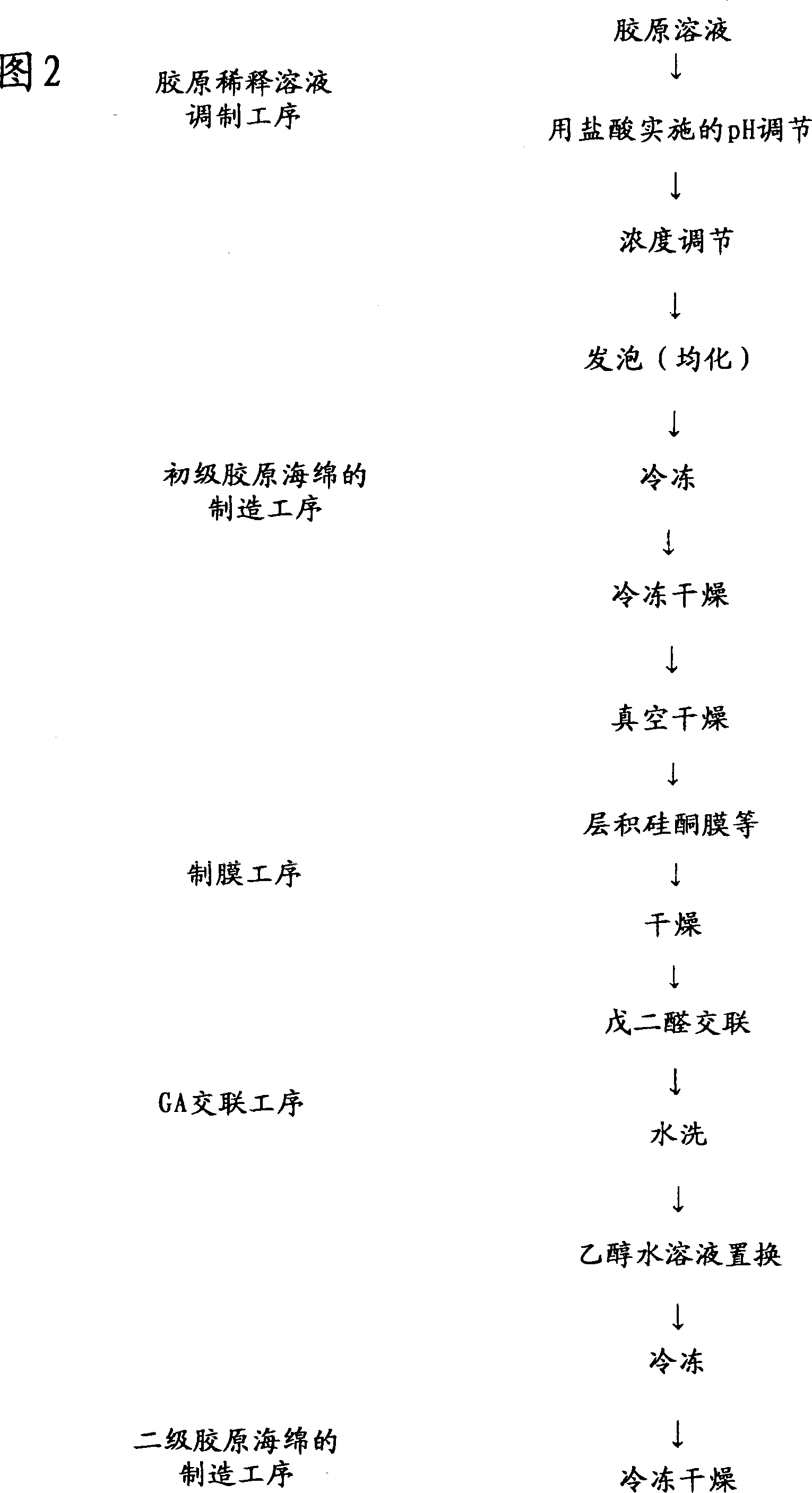

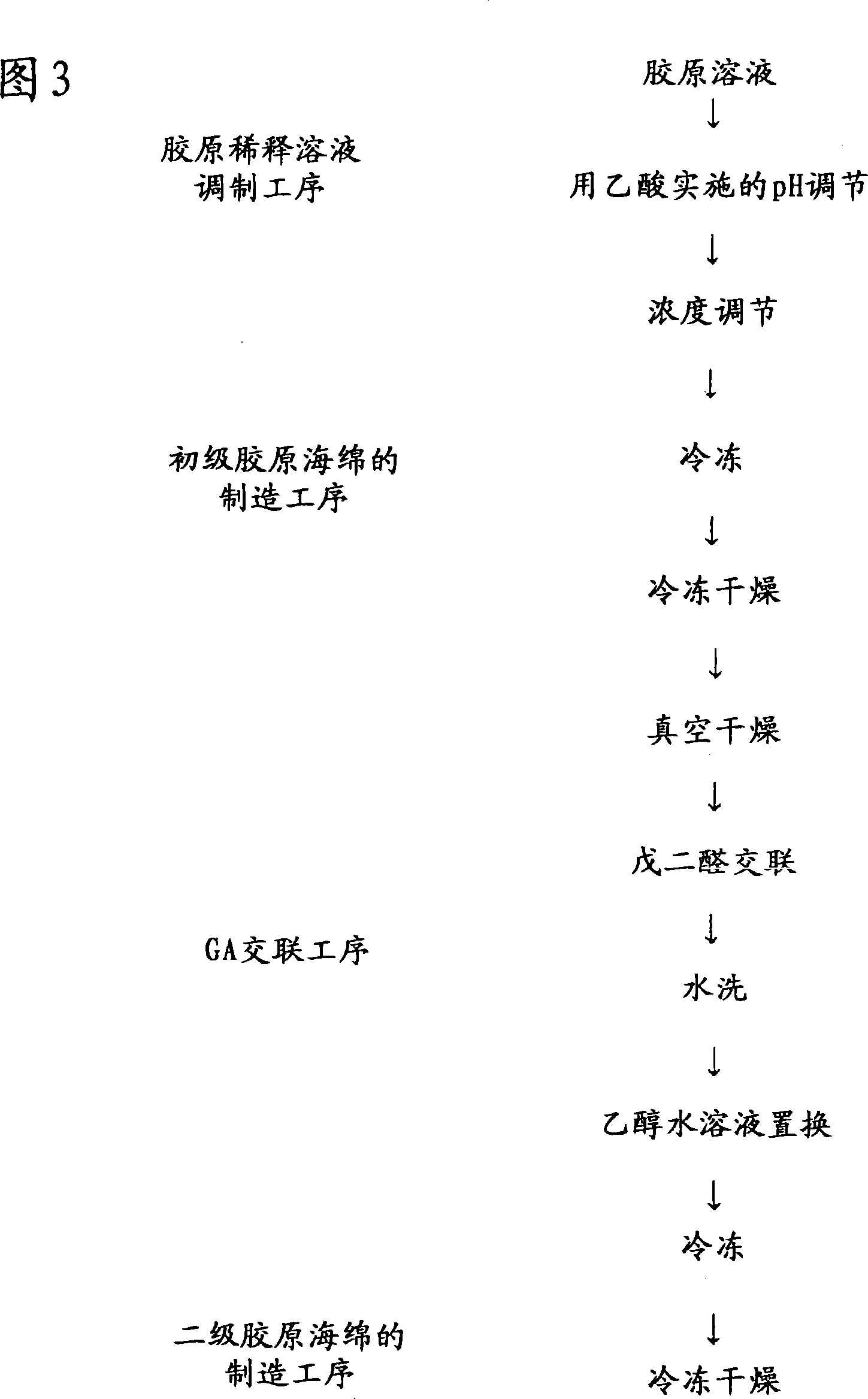

Method used

Image

Examples

Embodiment 1

[0077] Collagen solution (manufactured by Nitta Gelatin, "Atelo-collagen") was used as a raw material to prepare a diluted collagen solution with a concentration of 3 mg / mL and a pH of 3.0 using purified water, 5N acetic acid, and 1N hydrochloric acid.

[0078] 50 g of the obtained diluted collagen solution was poured into a stainless steel frame (11 cm×8.5 cm) for freeze-drying. The stainless steel frame was cooled to -40°C, the collagen foaming solution was frozen, and freeze-dried at 30°C for 24 hours under reduced vacuum (0.01 mmHg). Then, under vacuum and reduced pressure (0.01 mmHg), heat drying was carried out at 105°C for 24 hours to obtain a primary collagen sponge.

[0079] Then, a crosslinking reaction was carried out at 5° C. for 24 hours in a 0.2% by weight glutaraldehyde / acetic acid solution. The obtained cross-linked collagen sponge was sufficiently washed with ion-exchanged water, and then replaced with 15% ethanol aqueous solution.

[0080]Thereafter, it was...

Embodiment 2

[0083] Collagen solution (manufactured by Nitta Gelatin, "Atelo-collagen") was used as a raw material to prepare a diluted collagen solution with a concentration of 3 mg / mL and a pH of 3.0 using purified water, 5N acetic acid, and 1N hydrochloric acid.

[0084] To 50 g of the obtained diluted collagen solution, 0.5 g of chloroform was added. The resulting milky foaming liquid was poured into a stainless steel frame (11 cm×8.5 cm) for freeze-drying. The stainless steel frame was cooled to -40°C, the collagen foaming solution was frozen, and freeze-dried at 30°C for 24 hours under reduced vacuum (0.01 mmHg) to obtain a collagen sponge.

[0085] The obtained collagen sponge was added into an airtight container with a volume of 8000 mL, and 50 mL of the prepared 2% by weight glutaraldehyde / acetic acid solution was added in addition, and the solution was prevented from directly contacting the collagen sponge. The airtight container was left to stand at 40° C. for 3 hours to cross-...

Embodiment 3

[0088] Collagen solution (manufactured by Nitta Gelatin, "Atelo-collagen") was used as a raw material to adjust the collagen concentration to 3 mg / mL and pH 3.0 using purified water, 5N acetic acid, and 1N hydrochloric acid, and then added glutaraldehyde to make The final concentration of glutaraldehyde was 0.05 mM.

[0089] 50 g of the obtained diluted collagen solution containing glutaraldehyde was poured into a stainless steel frame (11 cm×8.5 cm) for freeze-drying. The stainless steel frame was cooled to -40°C, the collagen foaming solution was frozen, and freeze-dried at 30°C for 24 hours under reduced vacuum (0.01 mmHg). Then, under vacuum and reduced pressure (0.01 mmHg), heat drying was carried out at 105° C. for 24 hours to obtain a cross-linked collagen sponge.

[0090] A silicone film with a thickness of 100 μm was pasted on the obtained cross-linked collagen sponge and dried to obtain an artificial skin in which the silicone film was laminated on the collagen spon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com