Circular center focusing high power supersonic transducer

An ultrasonic transducer, center focusing technology, applied in the direction of sensors, device parts, sensor types, etc., can solve the problem of not being able to provide ring transducers, and achieve the effect of compact structure, good adaptability and low driving voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The drawings show various preferred embodiments of the present invention for purposes of illustration only. The structures and methods described by skilled artisans from the following discussion may alternative embodiments without departing from the principles of the invention.

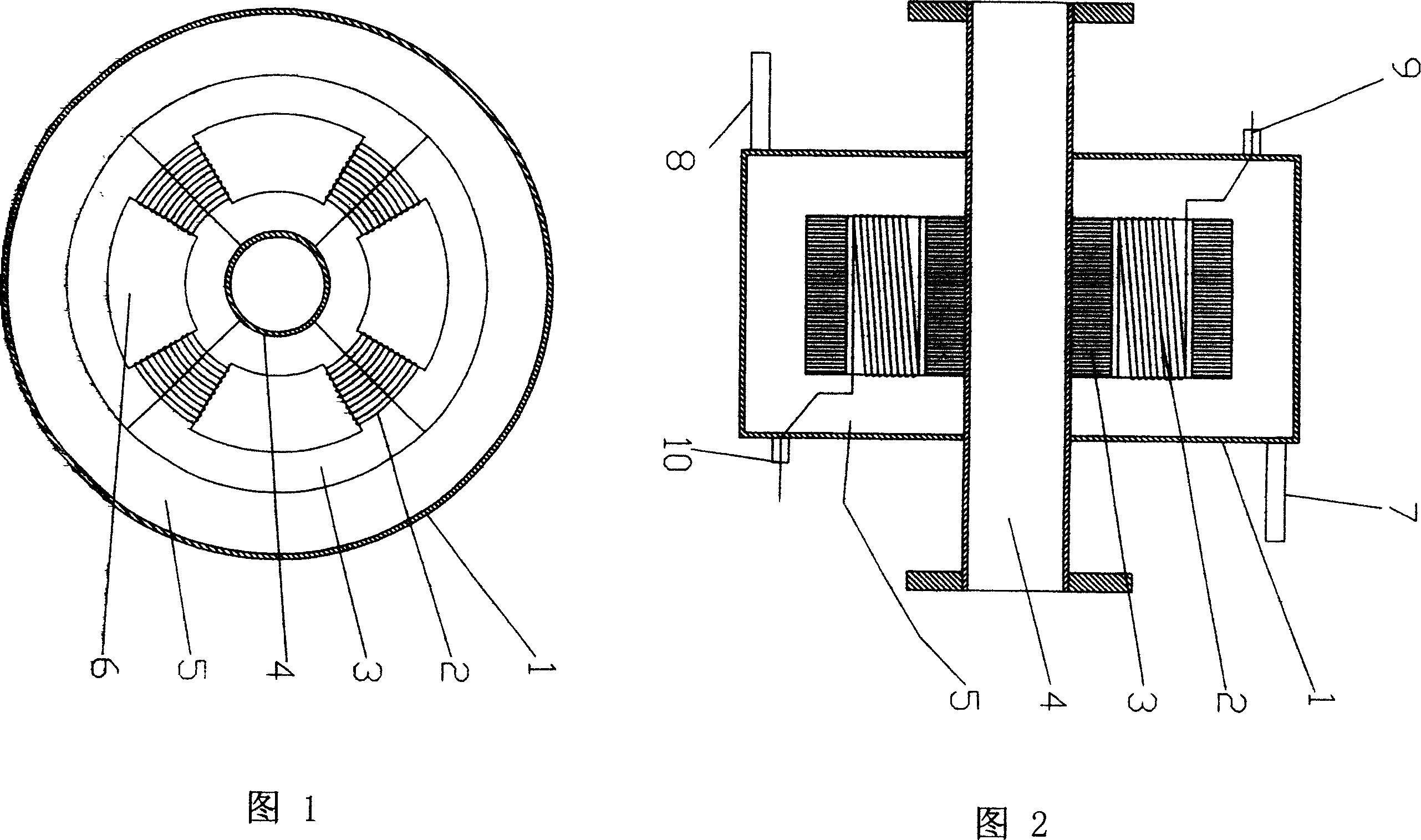

[0026] 1 and 2 show a schematic structural diagram of an embodiment of the transducer of the present invention. The transducer consists of a sector-shaped magnetostrictive lamination (3), a coil (2) wound on the lamination window to generate a driving magnetic field, a central radiant tube (4), a lamination window (6), and a cooling medium channel (5). , 6), cooling medium input and output ports (7, 8), transducer drive power interface (9, 10). The magnetostrictive material selected for the transducer is an annealed nickel sheet with a thickness of 0.3 mm. The nickel sheet is processed into a fan shape according to a 1 / 4 circle, and the surface is oxidized and passivated to improve the insulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com