Stator of multipole internal rotor permanent magnet generator

A permanent magnet generator and rotor-type technology, which is applied in the manufacture of stator/rotor bodies, magnetic circuits, electrical components, etc., can solve the problems of miniaturization, light weight and thinning, and the inability to make large power and parts Many problems, to achieve the effect of weight reduction, easy installation, and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

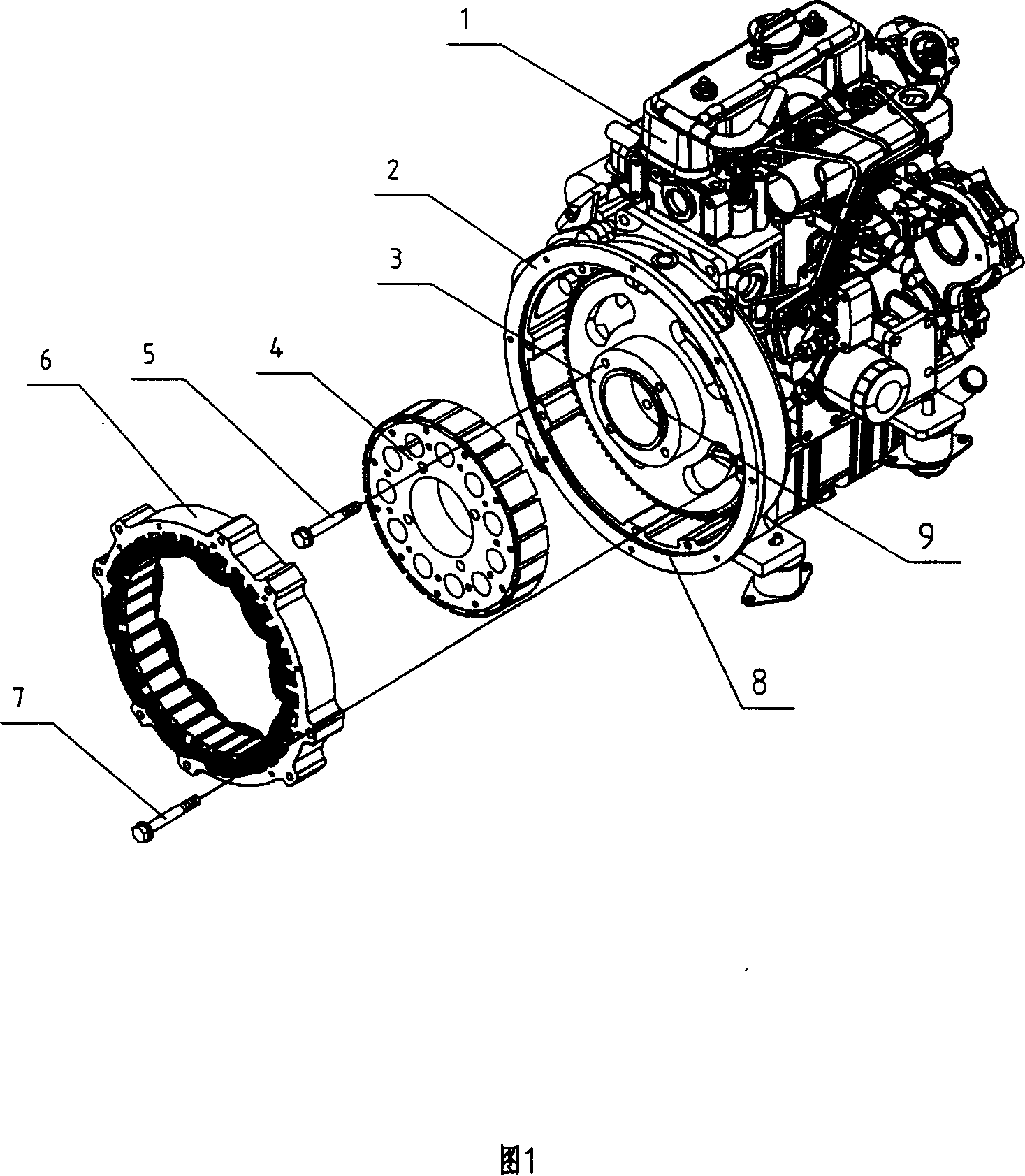

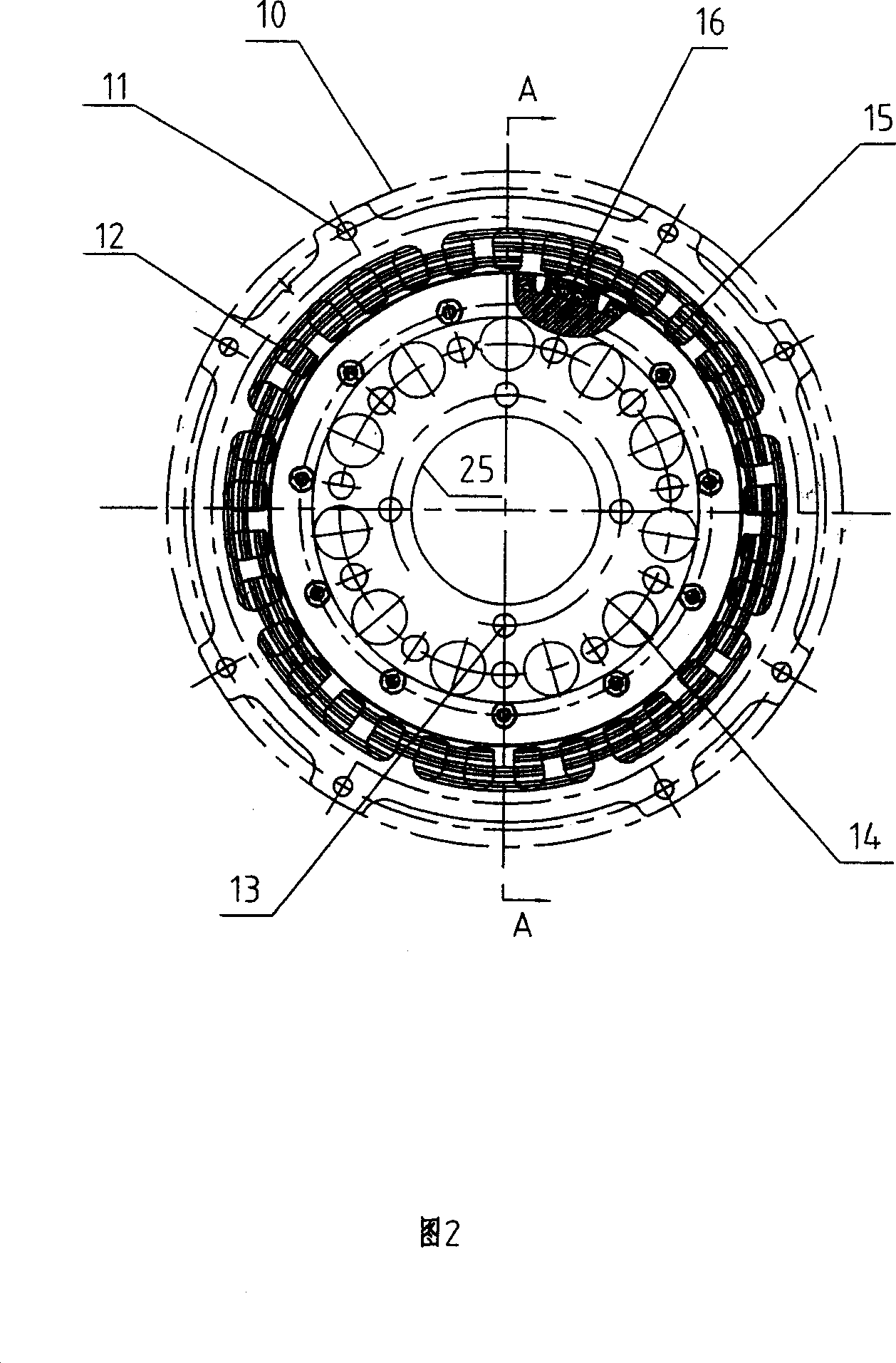

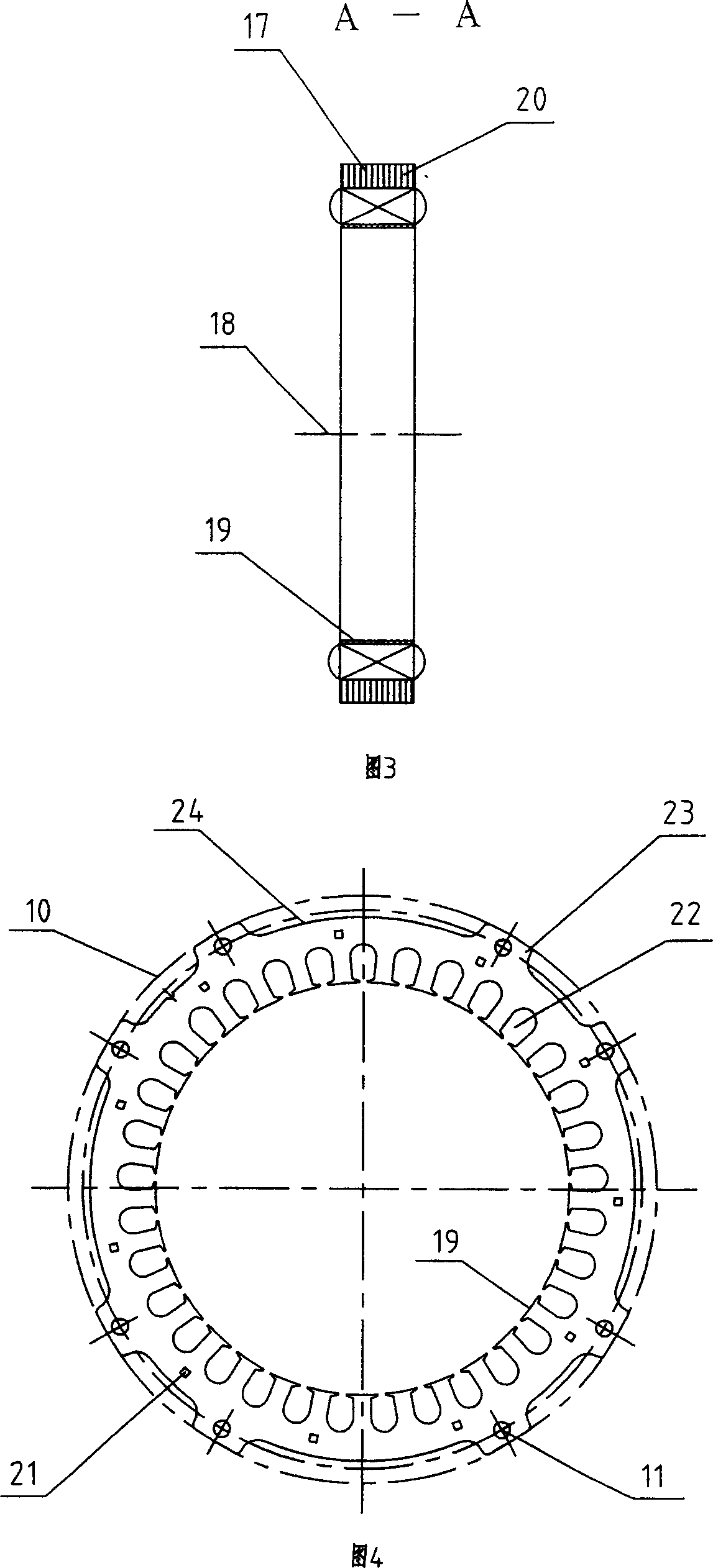

[0021] This embodiment is mainly composed of engine assembly 1, stator seat 2, rotor seat 3, rotor assembly 4, bolt 5, stator assembly 6, bolt 7, stator seat positioning opening 8, rotor seat positioning opening 9, stator positioning circle 10 , stator bolt hole 11, stator winding 12, rotor bolt hole 13, insert piece 15, permanent magnet 16, stator body 17, stator body rotation center 18, stator inner hole 19, stator punching sheet 20, stator self-locking slot 21, stator Wire groove 22, stator boss 23, stator groove 24, positioning circle 25 etc. are formed in the rotor. As shown in Figures 1 and 2: the stator assembly 6 of the present invention and the rotor assembly 4 comprising permanent magnets 16 form a generator, and the generator and an engine assembly 1 form a generator set. The stator assembly 6 of the present invention is composed of a stato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com