Steel tube anti-flex energy dissipation support

A technology of anti-buckling energy dissipation, steel pipe, applied in the direction of earthquake resistance, structural elements, building components, etc., can solve the problems of difficulty in production and installation, obstacles to popularization and application, high price, etc., achieve simple manufacturing process, prevent local instability and high cost. The effect of order buckling, low requirements on fabrication and installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

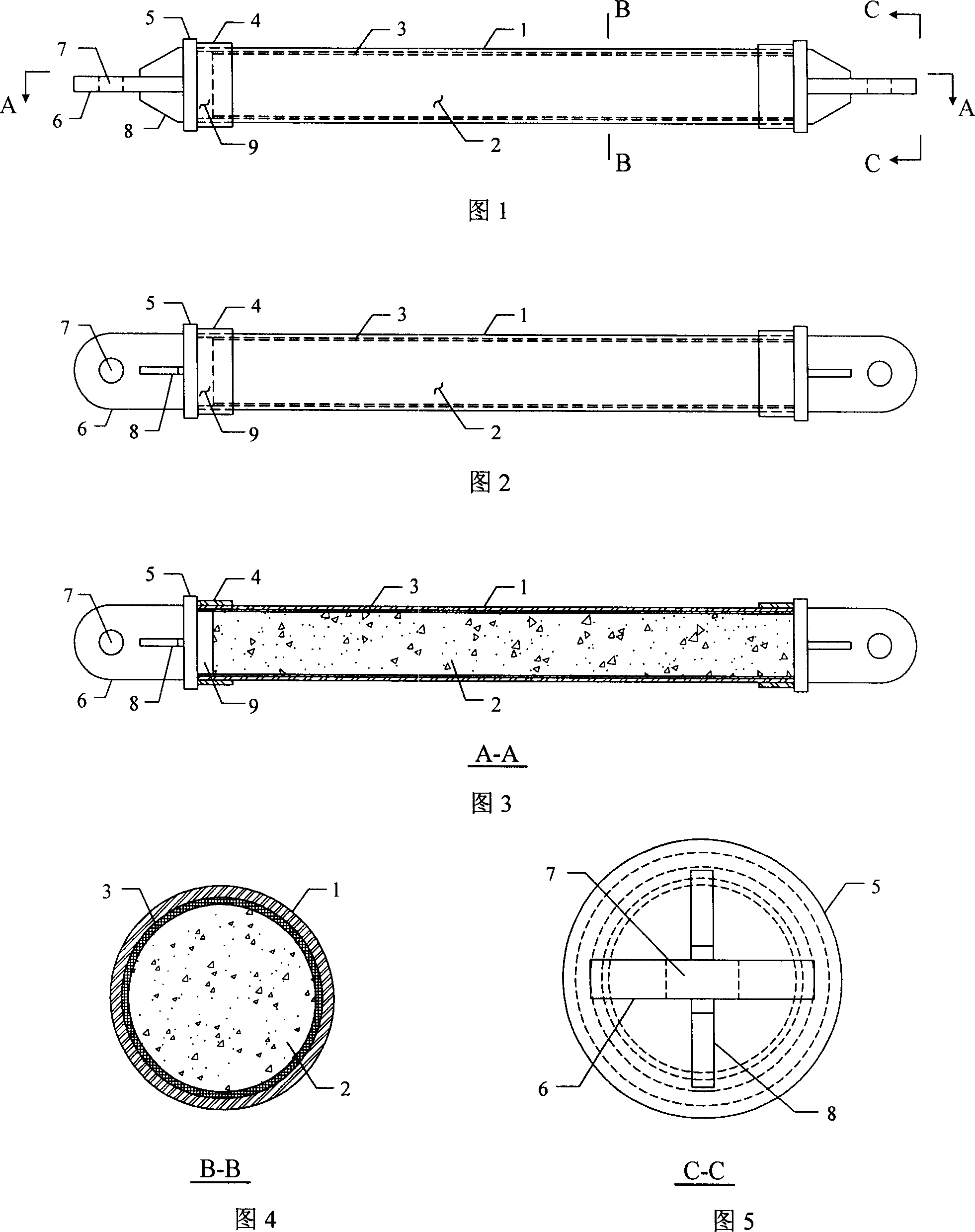

[0018] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0019] Fig. 1 is a front view of the steel pipe anti-buckling energy-dissipating support provided by the present invention. The anti-buckling energy dissipation support of the steel pipe in the present invention is composed of a steel pipe axial force unit, a buckling restraint unit, an isolation unit and a connection unit; The unit is composed of concrete 2 poured inside the axial force unit of the steel pipe, and the concrete can be lightweight aggregate concrete; the isolation unit is arranged between the round steel pipe 1 and the concrete 2, and is made of a pressure-resistant low-friction film material or a pipe; The connecting unit is composed of reinforcing steel rings 4, end plates 5 and connecting plates 6 arranged at both ends of the axial force unit, and the reinforcing steel rings are welded to the end plates. A circular connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com