Microcrystal glass made from titanium-containing magnetic iron are tailings

The technology of glass-ceramic and titanomagnetite is applied in the field of glass-ceramic made from titanomagnetite tailings, which can solve the problems of pollution of Jinsha River and other problems, and achieve the effects of reducing production cost, rational formula design and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

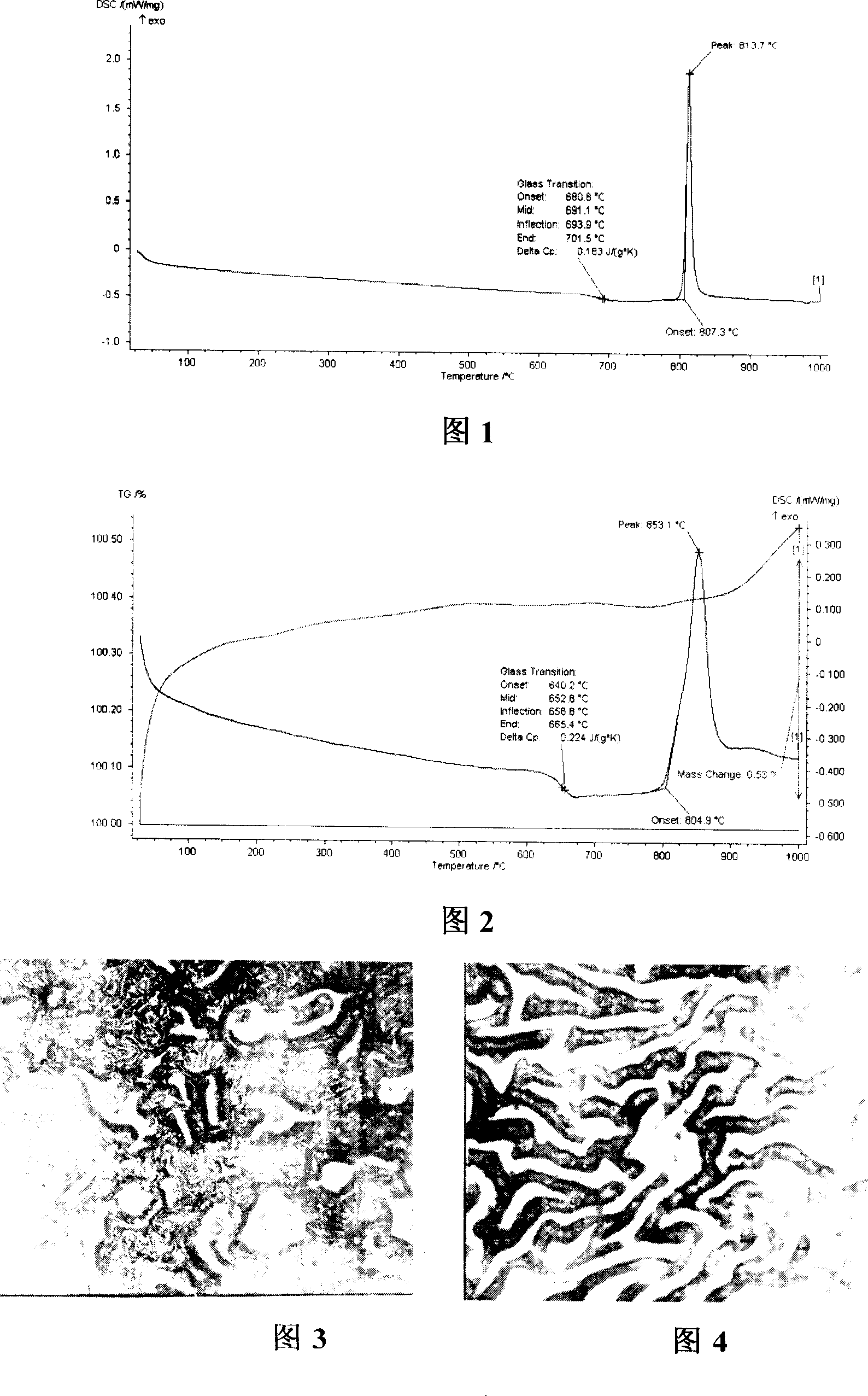

[0022] Aiming at the development and utilization of the titanium-containing magnetite tailings in Panzhihua, the present invention directly uses the vanadium-titanium magnetite tailings as the raw material for the production of glass-ceramics according to the composition characteristics of the vanadium-titanium magnetite tailings, with high content of TiO 2 It is a crystal nucleating agent and fluxing agent with excellent performance. The glass composition contains CaO, MgO, Al 2 O 3 , Fe 2 O 3 Mainly introduced by tailings, basically no external addition; additional SiO 2 In order to reduce the relative content of CaO and MgO, improve the crystallization performance of glass, because SiO 2 It is a glass network forming body, which is the main component, and the content cannot be too low; but it cannot be too high, and the viscosity of the glass will increase if it is too high.

[0023] The key to making glass-ceramics from Panzhihua titanium-containing magnetite tailings is to us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com