Split type electric pressure cooker

An electric pressure cooker and split type technology, applied in the field of pressure cookers, can solve the problems of not being able to be used alone, endangering safety, failure of sensors and circuit boards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

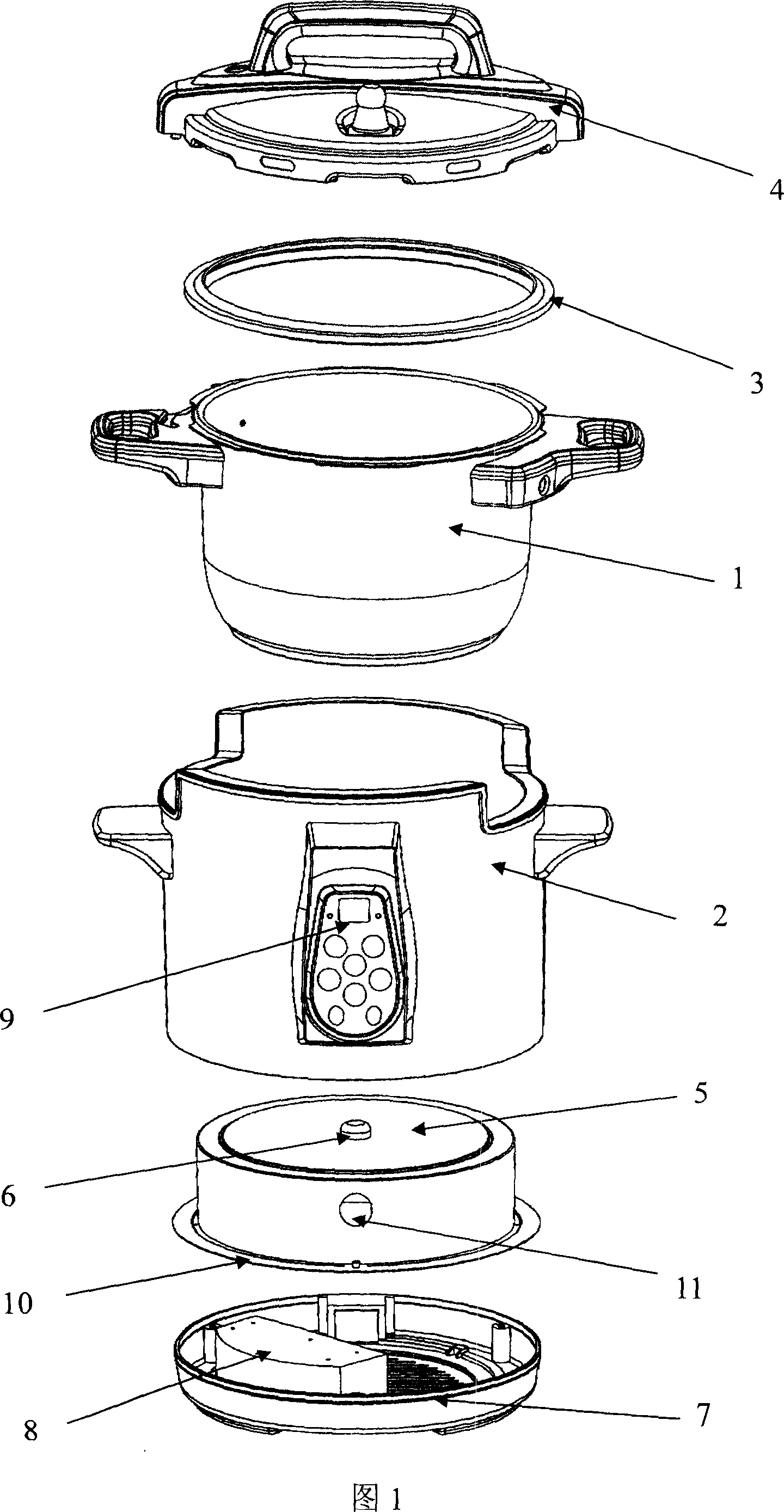

[0009] As shown in the figure, a split electric pressure cooker includes an inner pot 1 and an outer pot 2 . The inner pot 1 is a pressure cooker that can be used alone. It is manufactured according to the GB-15066-2004 standard for stainless steel pressure cookers. The sealing ring 3 is placed on the upper edge of the inner pot 1 to strengthen the seal between the inner pot 1 and the lid 4, and can be directly heated with an open flame.

[0010] The heating device is as follows: a heating plate 5 is arranged at the bottom of the outer pot 2, a thermistor 6 is arranged in the middle of the heating plate 5, and a microcomputer control device 8 is arranged in the base 7 of the outer pot 2, and the microcomputer control device 8 adjusts the thermosensitive The resistance value of the resistor 6 controls the heating intensity of the heating disk 5 . The housing of the outer pot 2 is provided with a control panel 9 for operating the microcomputer control device 8, which can reserve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com