Method for synthesizing diaryl carbonic acid ester and dimethyl ether by one-step method and catalyst

A diaryl carbonate and synthesis method technology, applied in the direction of organic carbonate preparation, organic chemistry, etc., can solve the problems of incomplete DMC reaction, shortening the reaction process, etc., to shorten production time, reduce production cost, and improve conversion The effect of rate sum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

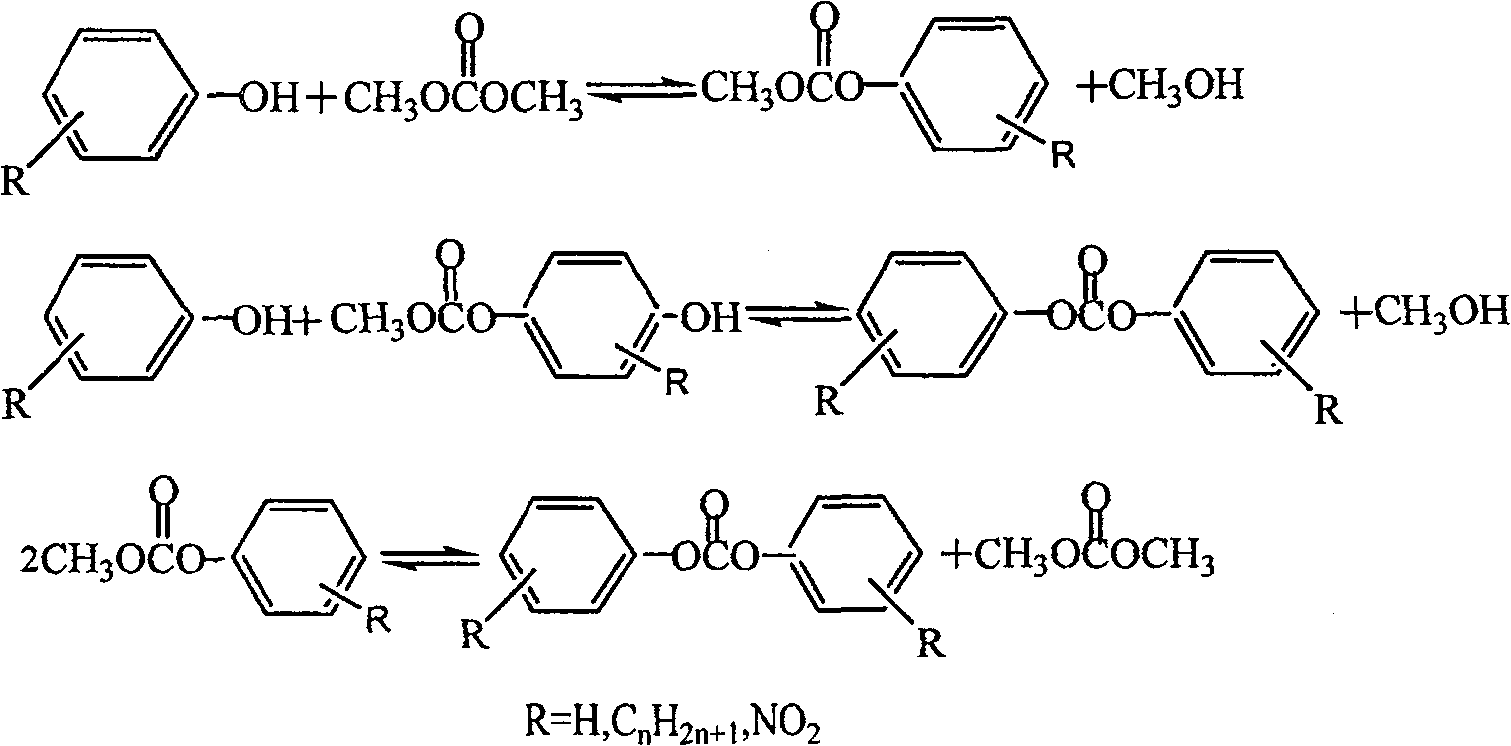

Method used

Image

Examples

example 1

[0024] Example 1. Add the catalyst V of the good transesterification reaction of physical mixing in the reactor 2 o 5 And dehydration catalyst HZSM-5 1.4g, its ratio is: V 2 o 5 :HZSM-5=2:1 (mass ratio), then add 94.0g of phenol and 45.0g of DMC respectively. Stirring was started, and the temperature was gradually increased to 190°C. After 5.0 hours of reaction, 10.2 g of DME was obtained, and the yield of DME was 90.5%. The mixture in the reactor was filtered while it was hot, and the catalyst was recovered. The filtrate was distilled under reduced pressure at 4 mmHg and 150° C., and unreacted phenol was recovered when the fraction temperature was around 60° C. The conversion rate of phenol reached 49.0%. The crude product of DPC was obtained at a distillate temperature of about 130°C. The crude product was dissolved in hot absolute ethanol, then cooled to 10°C for crystallization, and filtered to obtain 49.2g of pure DPC, with a DPC yield of 46.0%.

example 2

[0025] Example 2. Add the catalyst V of the good transesterification reaction of physical mixing in the reactor 2 o 5 And dehydration catalyst HZSM-5 1.0g, the ratio is: V 2 o 5 : HZSM-5=2:1 (mass ratio), then add p-nitrophenol 70.0g, DMC 22.5g respectively. Stirring was started, and the temperature was gradually increased to 190°C. After 5.0 hours of reaction, 4.7 g of DME was obtained, and the yield of DME was 90.4%. Filter the mixture in the reaction kettle while it is hot to recover the catalyst. The filtrate is subjected to vacuum distillation at 3mmHg and 160°C. When the distillate temperature is around 80°C, the unreacted p-nitrophenol is recovered, and the conversion of p-nitrophenol The rate reached 44.8%. The distillate temperature is about 140°C to obtain the crude product of di-p-nitrocarbonate. Dissolve the crude product in hot absolute ethanol, then cool the temperature to 10°C for crystallization, and filter to obtain 30.0g of pure p-nitrocarbonate , The yi...

example 3

[0026] Example 3. Add the catalyst V of the good transesterification reaction of physical mixing in the reactor 2 o 5 And dehydration catalyst HZSM-5 0.9g, its ratio is: V 2 o 5: HZSM-5=2:1 (mass ratio), then add p-ethylphenol 61.0g, DMC 22.5g respectively. Stirring was started, and the temperature was gradually increased to 190° C. After 6.0 hours of reaction, 4.8 g of DME was obtained, and the yield of DME was 92%. Filter the mixture in the reaction kettle while it is hot to recover the catalyst. The filtrate is distilled under reduced pressure at 3mmHg and 160°C. When the distillate temperature is around 80°C, the unreacted p-ethylphenol is recovered, and the conversion of p-ethylphenol The rate reached 45.4%. The distillate temperature is about 135°C to obtain the crude product of di-p-ethyl carbonate. Dissolve the crude product in hot absolute ethanol, then cool the temperature to 10°C for crystallization, and filter to obtain 27.6g of pure p-nitrocarbonate , The yie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com