Rotary two-stage compressor

A rotary compressor technology, applied in the field of rotary compressors, can solve the problems of increased leakage loss of coolant or refrigerating machine oil, differences in dimensional accuracy, surface accuracy, and increased deformation of the end plate portion 19b, so as to reduce sliding loss , the effect of improving performance and reducing leakage loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

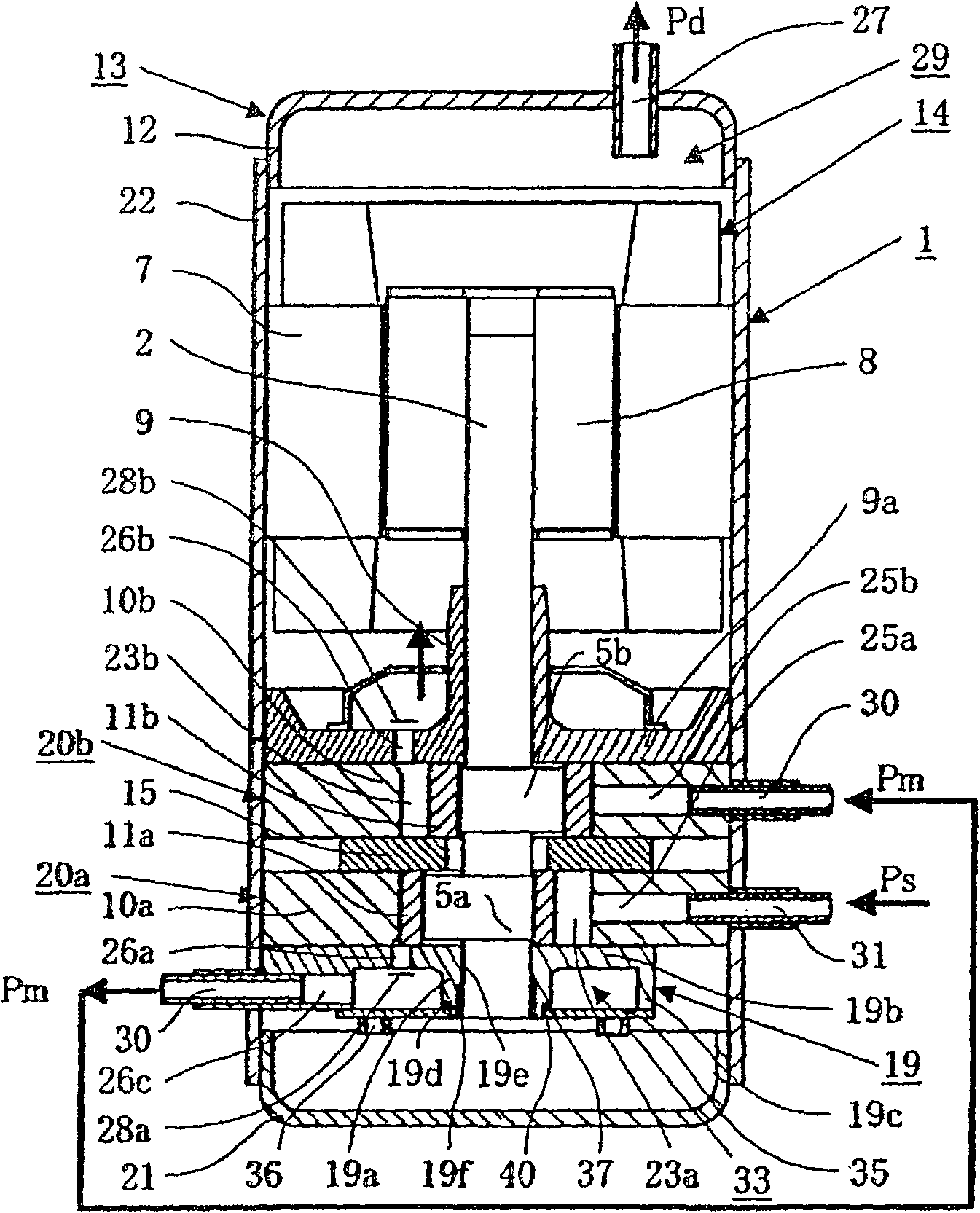

[0040] use Figure 1 to Figure 7 , an embodiment of the present invention will be described. figure 1 It is a vertical cross-sectional view of a rotary two-stage compressor according to an embodiment of the present invention. exist figure 1 in, right with Figure 10 The same symbols are assigned to the same components and materials.

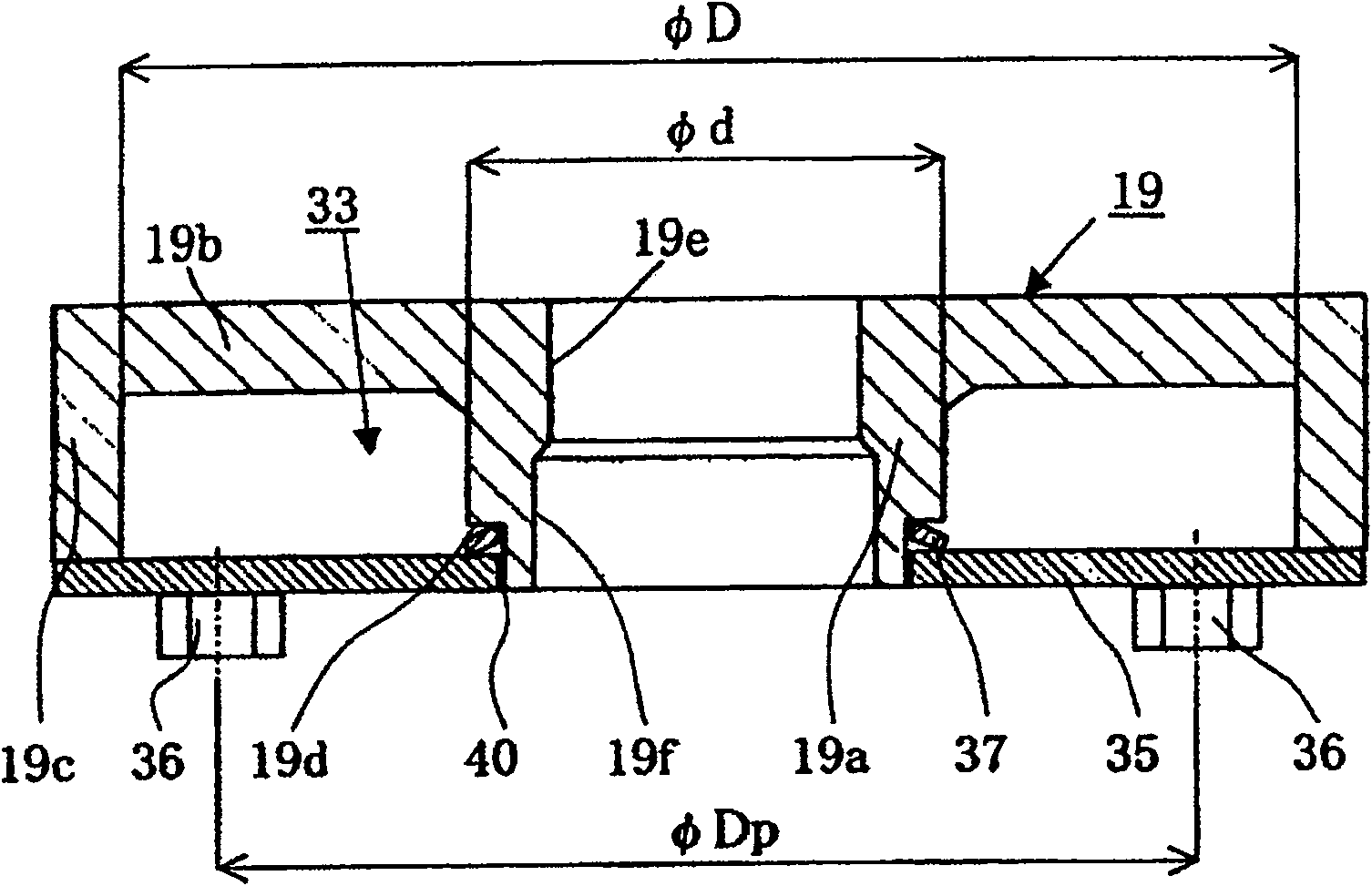

[0041] The compressor 1 has an airtight container 13 composed of a bottom 21 , a cover 12 and a body 22 . Above the inside of the airtight container 13, a motor 14 having a stator 7 and a rotor 8 is provided. The rotary shaft 2 to which the motor 14 is connected has two eccentric portions 5a, 5b, and supports the main bearing 9 and the sub-bearing 19a. Corresponding to the rotating shaft 2, the main bearing 9 having the end plate portion 9a, the high pressure compression element 20b, the intermediate partition plate 15, the low pressure compression element 20a, and the end plate portion shared with the low pressure compression element 20a a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com