Windshield wiping device, especially for a motor vehicle

A technology for wipers and car bodies, which is used in vehicle cleaning, vehicle maintenance, transportation and packaging to achieve the effects of cost-effective technology and cost-effective manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

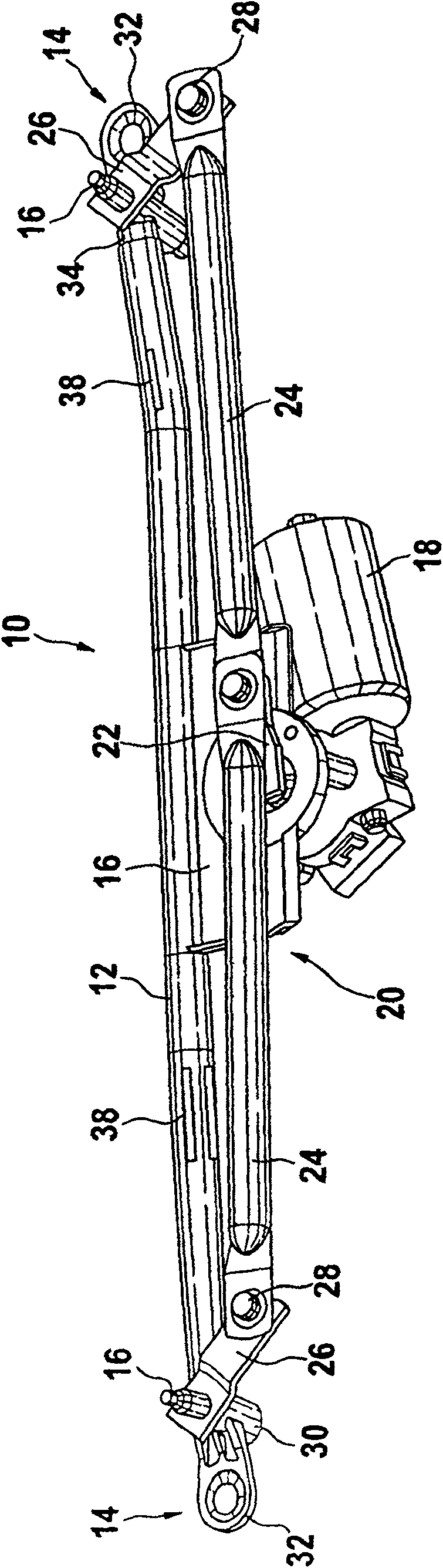

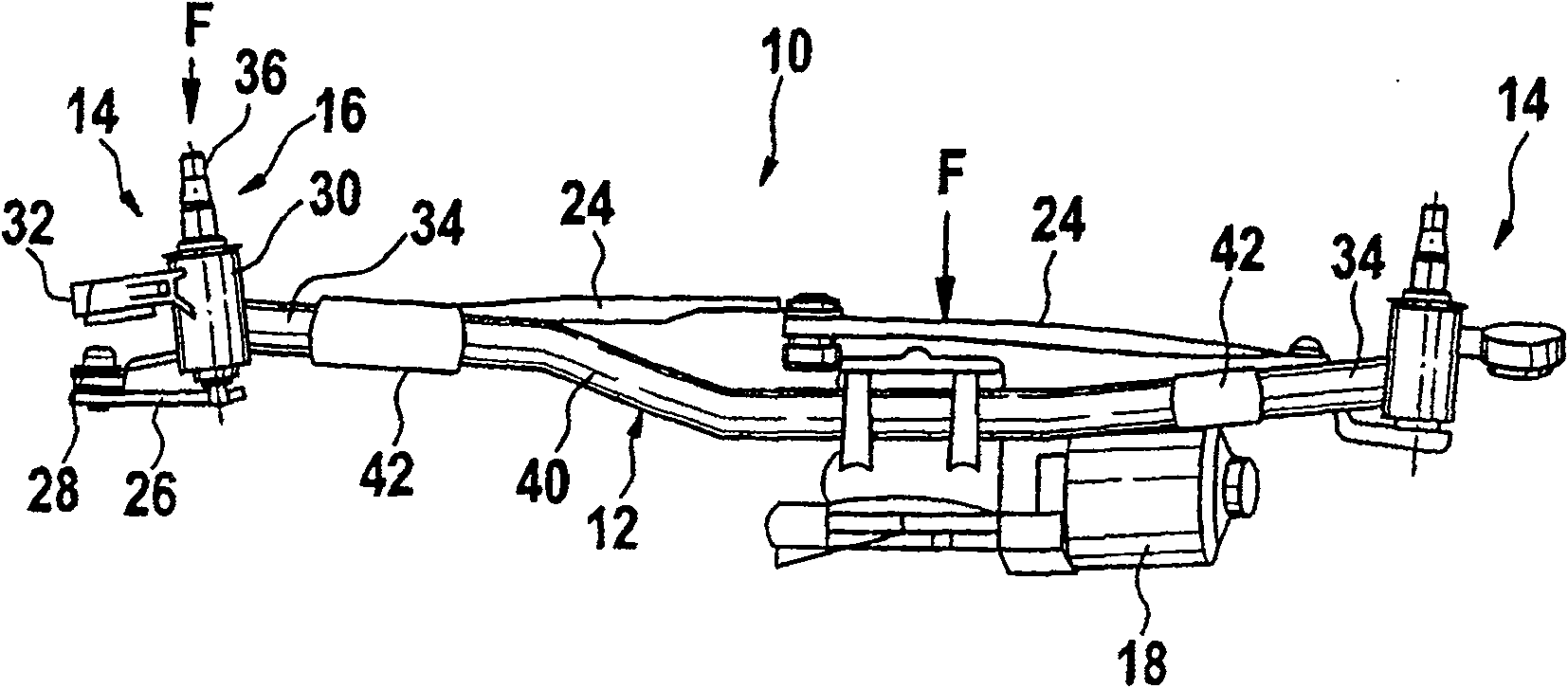

[0019] figure 1 is a perspective view of a windshield wiper device 10 according to the invention.

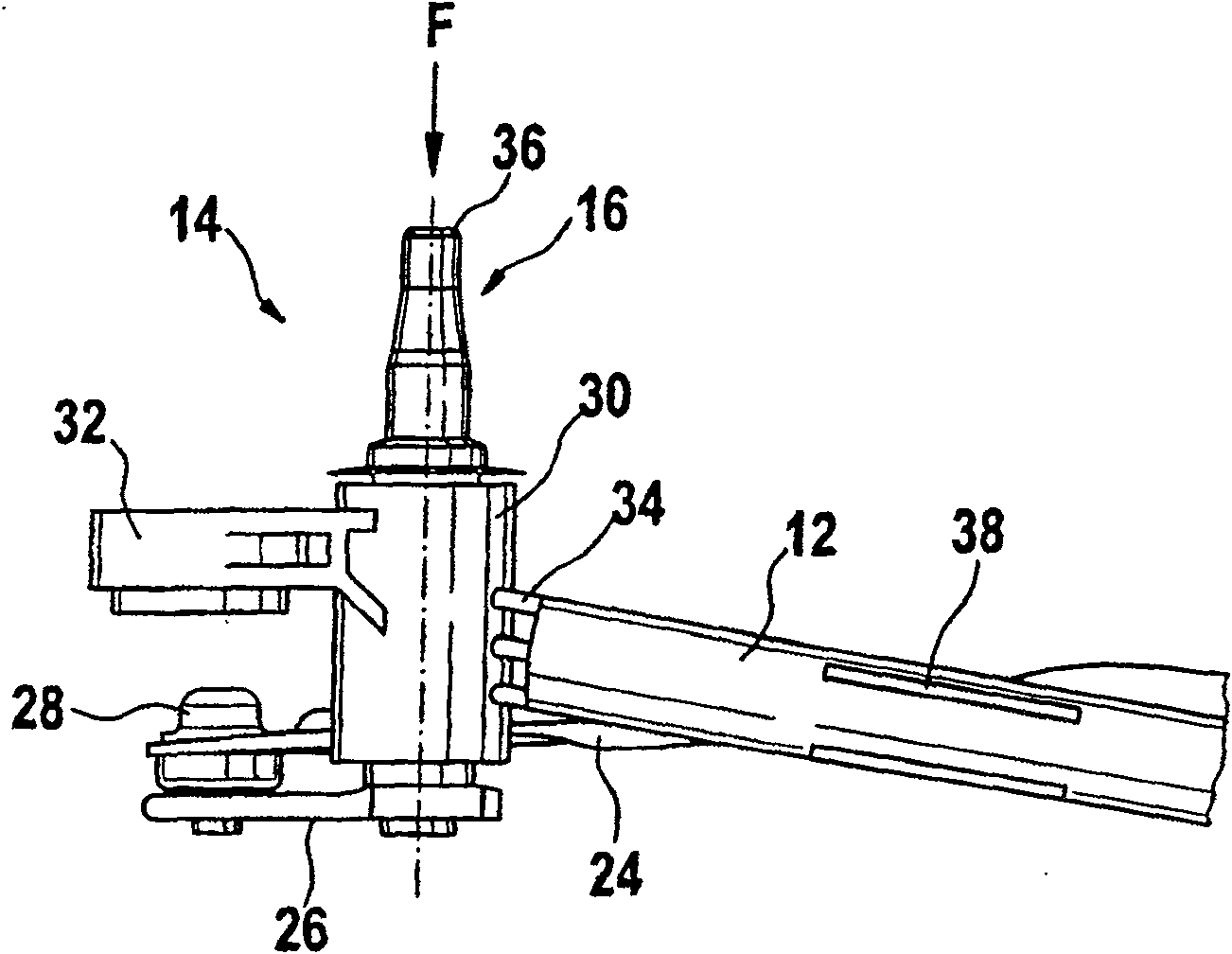

[0020] The wiper device 10 comprises a plurality of components 12 , 14 , 16 , 18 , 20 , in particular a support tube 12 , at each end of which a wiper bearing 14 is fastened. A wiper shaft 16 is mounted in each case in the wiper bearings 14 . These wiper shafts can be moved back and forth by means of a transmission 20 via the drive 18 . The transmission mechanism 20 includes a driven crank 22 , which can realize a reciprocating movement or a rotary movement via the drive mechanism 18 . Two pushrods 24 are articulated to the output crank 22 , which at their ends facing away from the drive crank 22 are each able to effect a pivoting movement of the drive crank 26 . To this end, the push rod 24 is connected to the drive crank 26 via a ball joint 28 . The drive crank 26 is in turn non-rotatably connected to the wiper shaft 16 , so that the wiper shaft achieves a reciprocating mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com