Method and apparatus for sealing air exhaust of large size plasma display screen

A plasma display and exhaust device technology, applied in the manufacture of electrical components, discharge tubes/lamps, cold cathodes, etc., can solve the problem of long exhaust and heating time, unsafe exhaust tailpipes, and no guarantee of safety and other issues, to achieve the effect of improving safety, improving exhaust effect and saving working gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

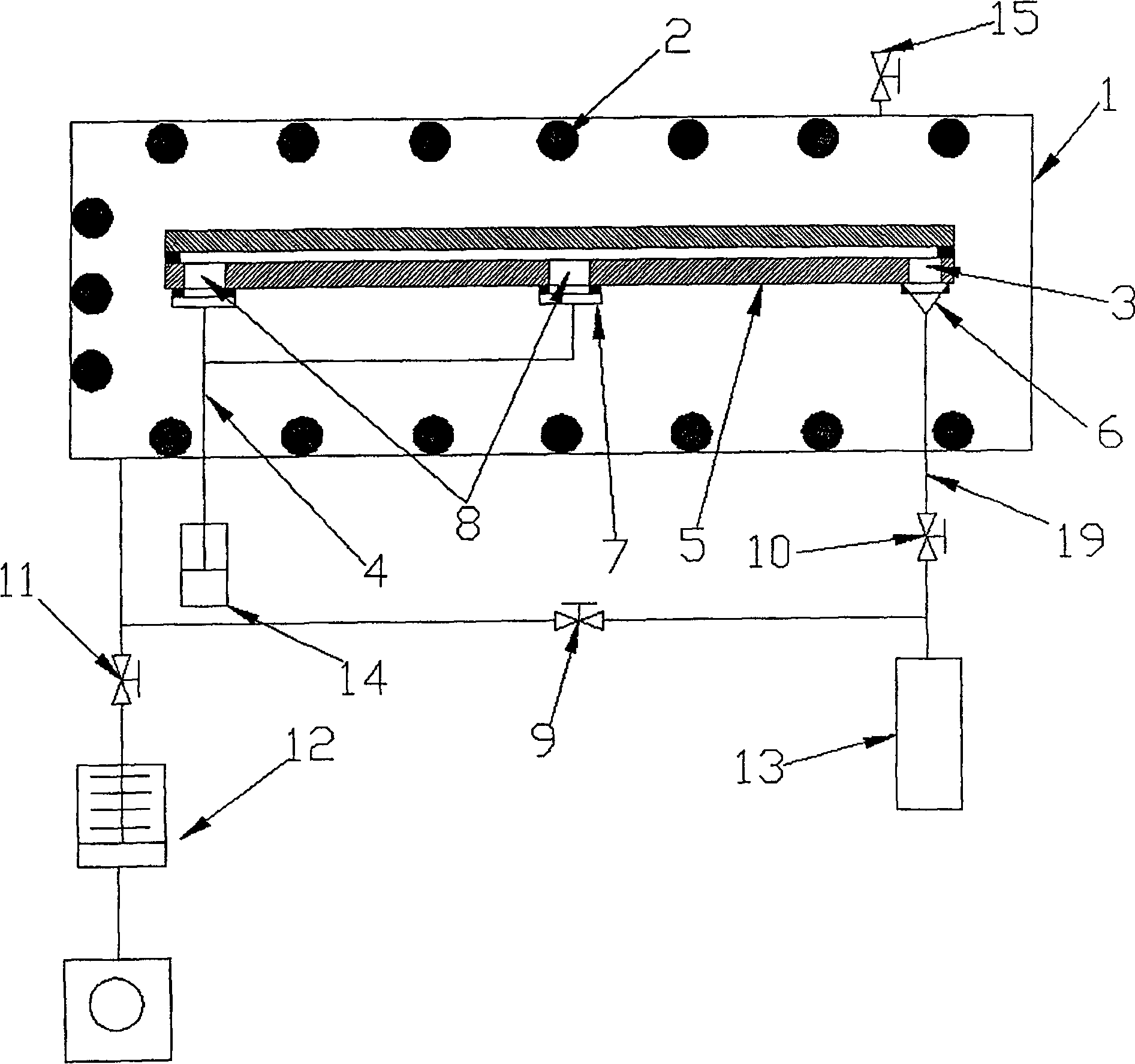

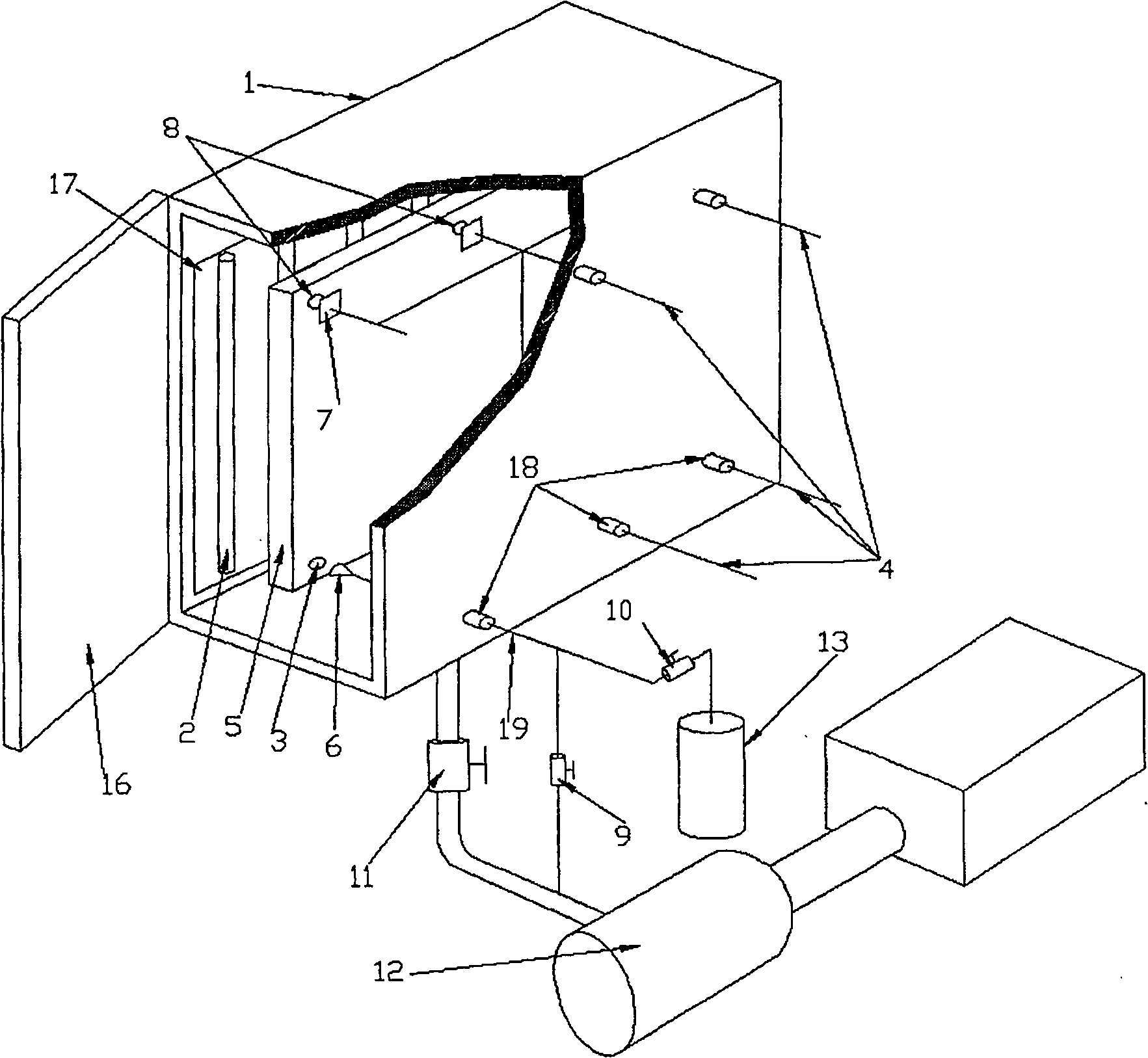

[0023] Attached below figure 1 , 2 And embodiment the present invention is described further.

[0024] A method for sealing and exhausting large-scale plasma display screens of the present invention comprises the following steps:

[0025] First, put the clamped front and rear glass substrates 5 into the vacuum heating container 1, so that the exhaust holes 8 and the filling / exhaust holes 3 on the rear glass substrate are respectively connected with the preset push rods 4 in the vacuum heating container 1. The glass cover 7 is aligned with the gas filling tube 6; secondly, open the exhaust system 11 and start to exhaust the vacuum heating container 1, the gas between the front and rear glass substrates 5 is discharged through the exhaust hole, and open the heater at the same time to start the vacuum heating container. 1 internal heating, third, when the internal temperature rises to the highest temperature, the compressed air cylinder (14) pushes the preset push rod 4, so tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com