Multiple fire hole flame-free ceramic burner

A ceramic burner and fire hole technology, which is applied in the field of flameless combustion ceramic burners and ceramic burners, can solve the problems affecting the heat exchange effect of the regenerator, improve the working condition of the vault, and achieve reasonable design and manufacturing construction easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

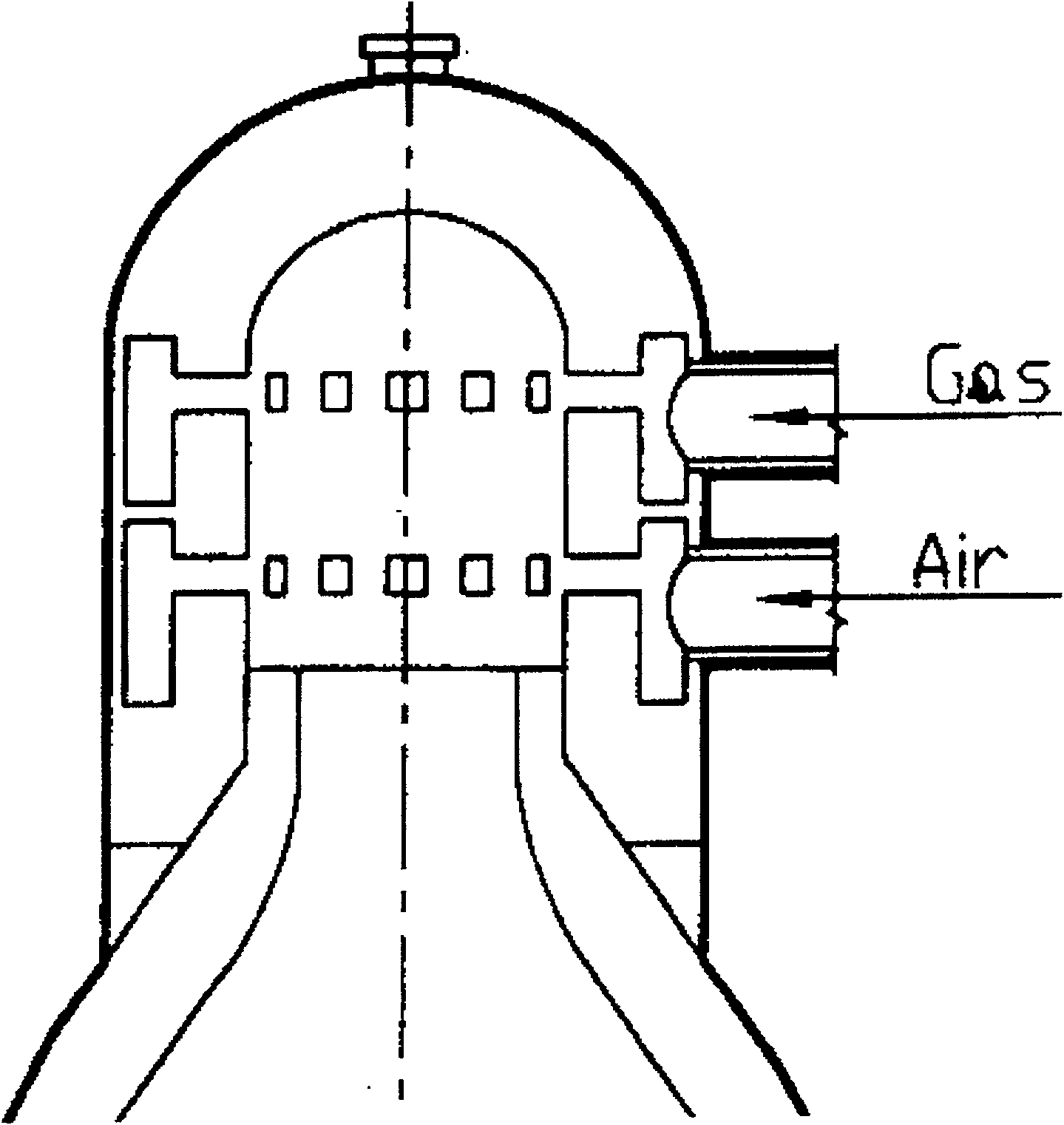

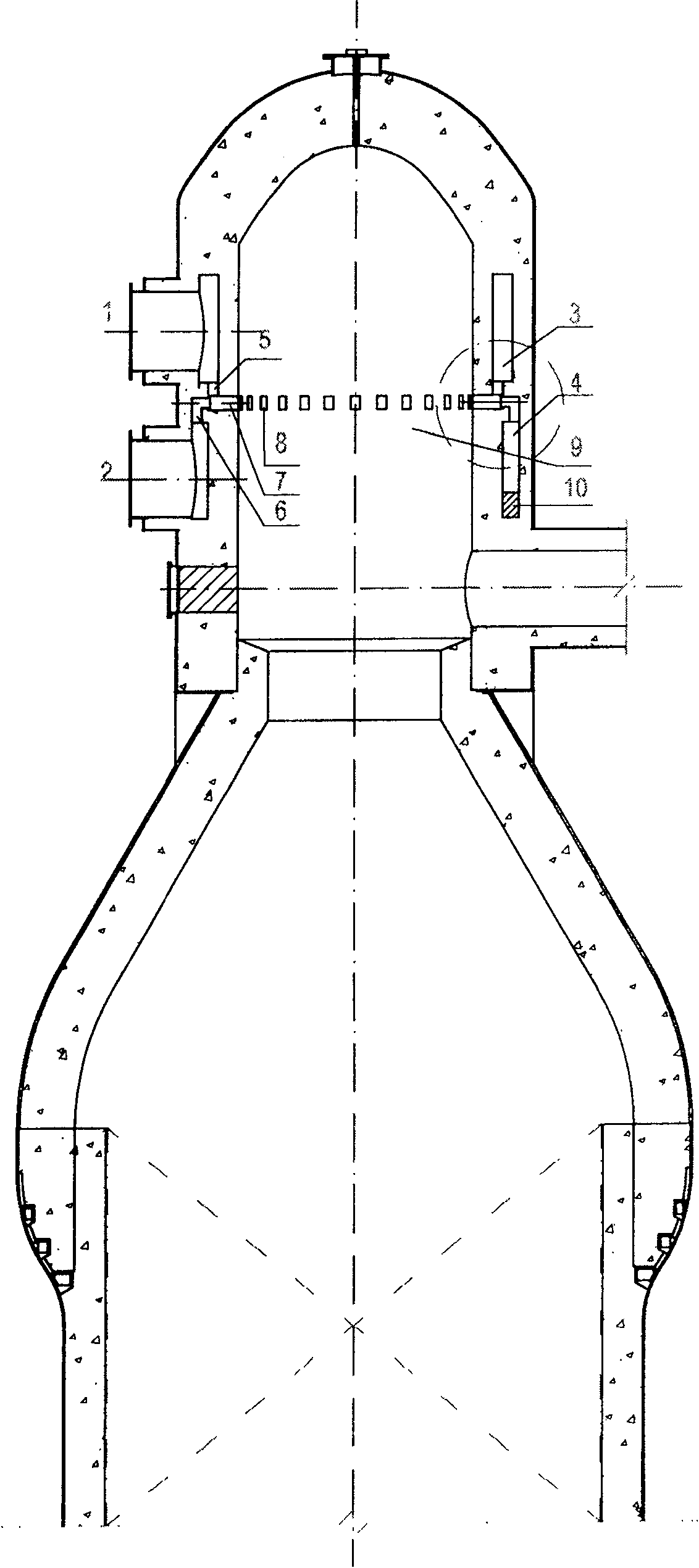

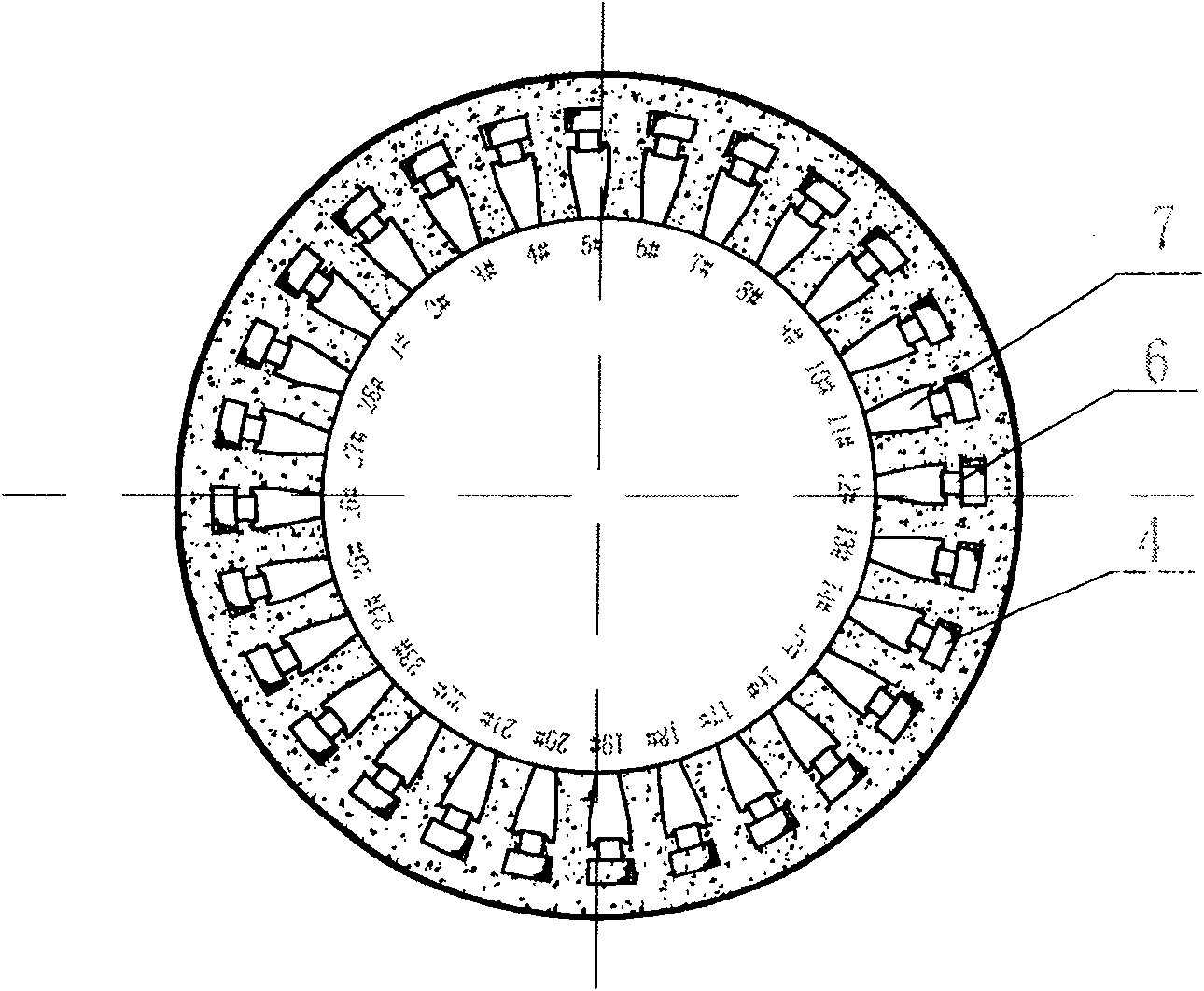

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings. as attached figure 2 As shown, the outer wall of the burner is provided with two upper and lower gas rings 3, 4, of which the air ring 3 is located above the gas ring 4, and guide bricks are also arranged in the gas ring to make the gas distribution more uniform . After the gas and combustion-supporting air are preheated in their respective rings 3 and 4, they enter the front section of the mixing channel 7 through the injection holes 5 and 6, and the gas injection holes 6 enter the mixing channel in a direction parallel to the centerline of the combustion port 8 7. The air injection hole 5 enters the mixing channel 7 at an angle of 90° to the center line of the combustion port 8 . The gas injection hole 6 is designed with the structure of the boss to prevent the gas from tempering. Under the action of the pressure of the gas jet flow and the air flow of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com