Major-minor multi-push injection mold pushing mechanism

A top type, main and auxiliary technology, applied in the field of main and auxiliary multi-top injection molding top mold mechanisms, can solve the problems of reduced service life of the mold, excessive support rod diameter, uneven force on the template, etc., to prolong the service life, occupy The effect of small space and easy processing and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

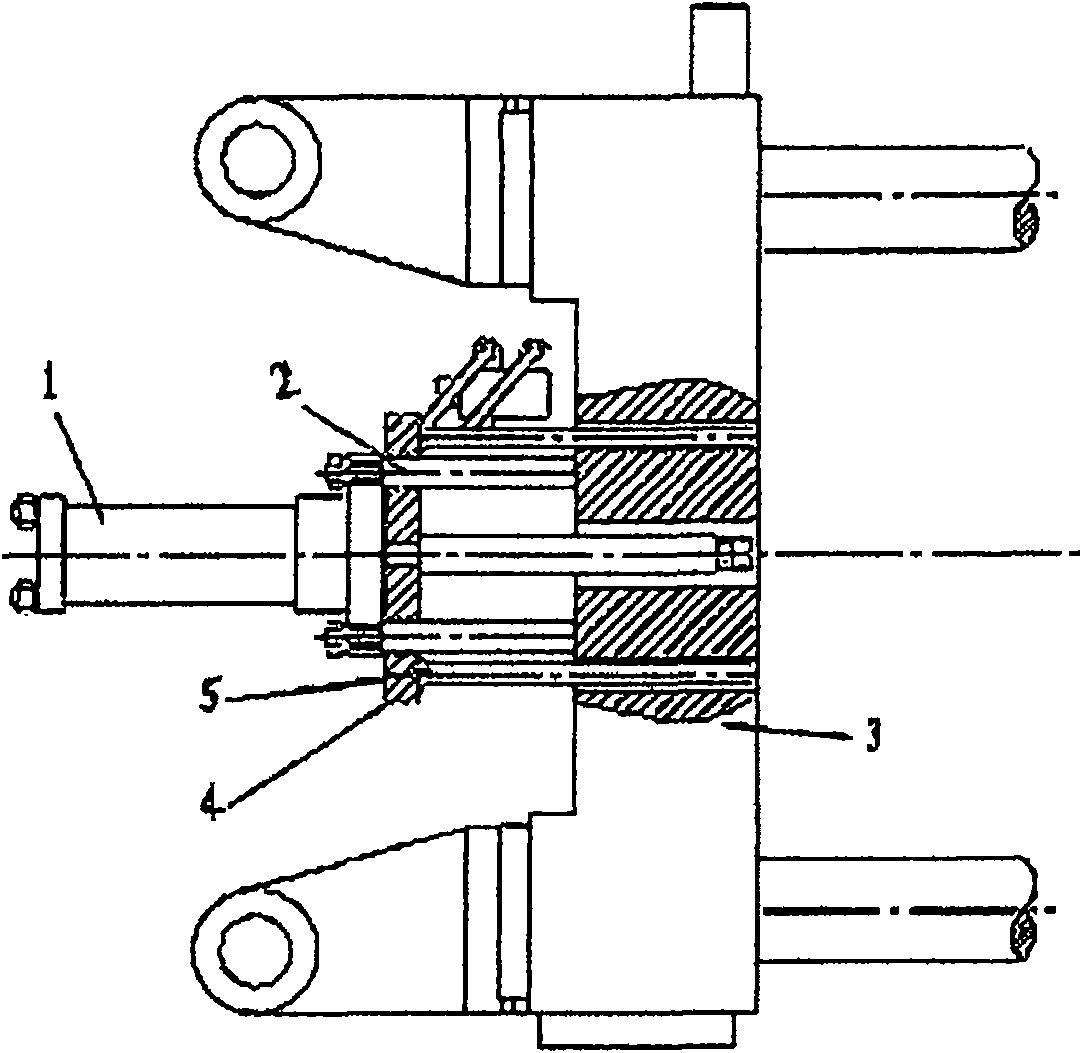

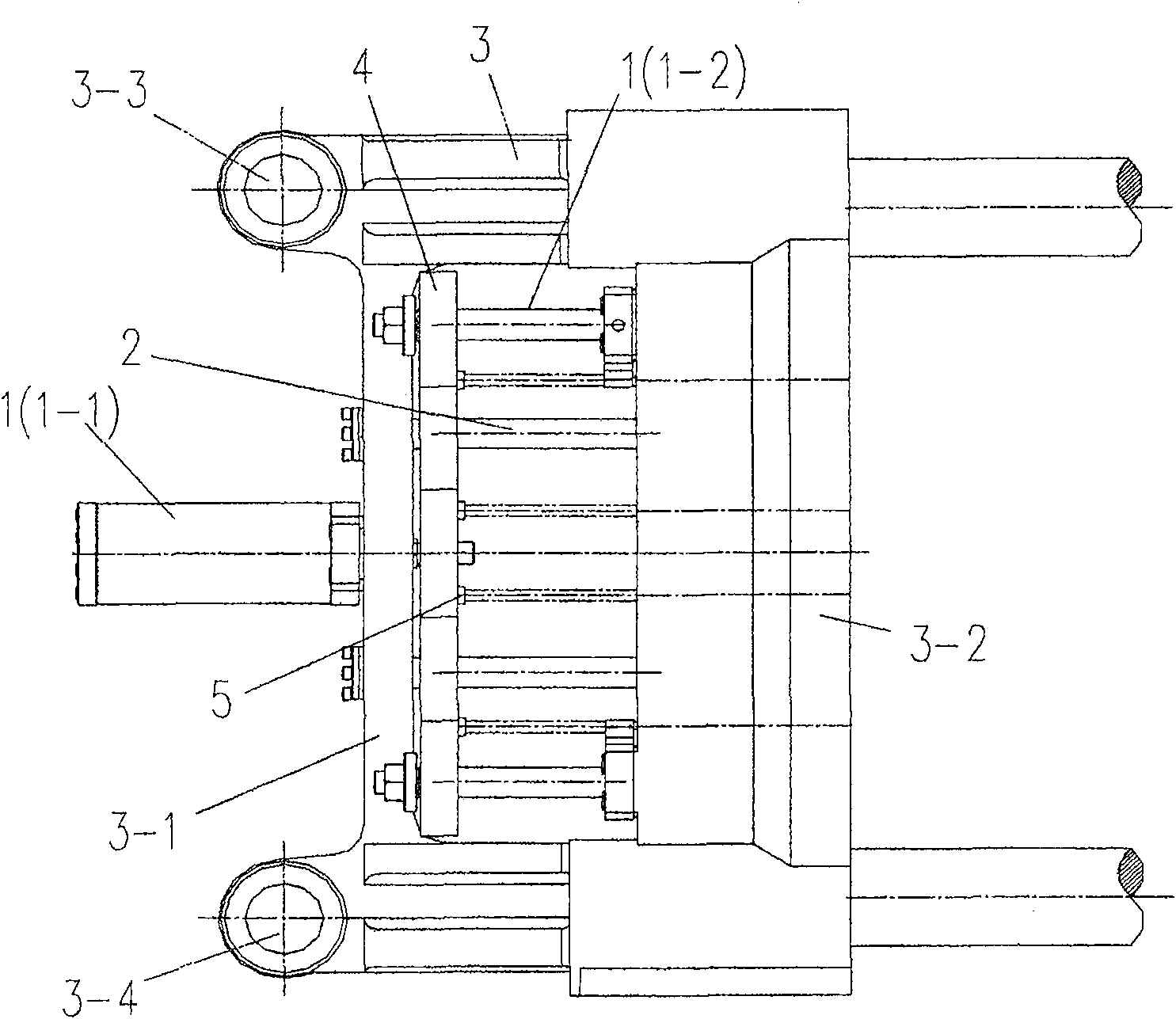

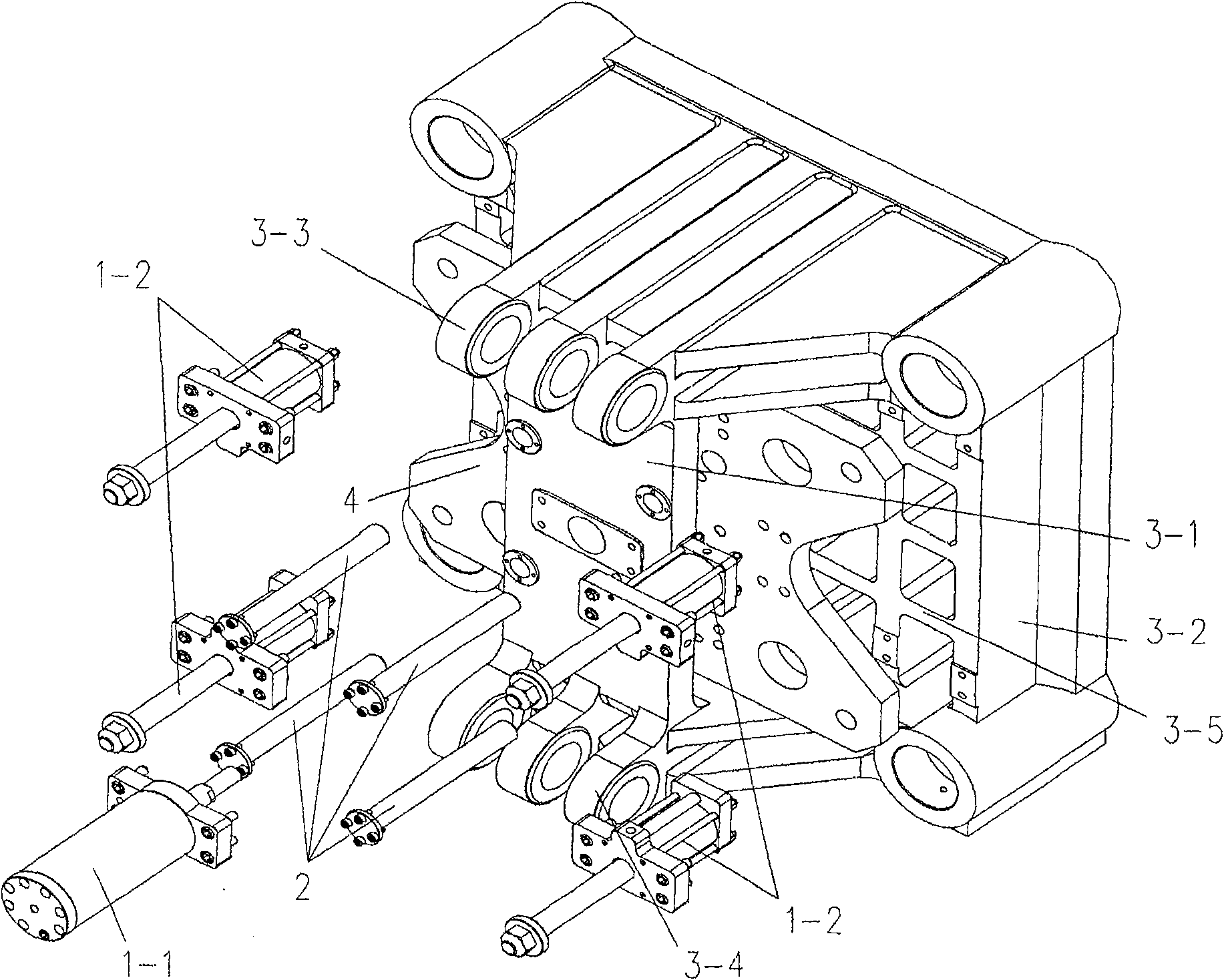

[0026] Figure 2 to Figure 5 A specific structure of the present invention is shown, by Figure 2 to Figure 5 It can be seen that the main and auxiliary multi-top injection molding top mold mechanism includes a movable template 3, an ejection cylinder 1, a support rod 2, an ejector plate 4, and an ejector rod 5. The ejector rods are connected, and the structure of the movable template 3 is as follows: Figure 5 As shown, a rib plate 3-1 is provided, and the rib plate 3-1 connects the upper and lower hinge parts 3-3, 3-4 of the movable template 3, and is parallel to the movable template main body 3-2, and the ejector plate 4 is located between the rib plate 3-1 and the main body of the movable formwork 3-2, the support rod 2 passes through the ejector plate 4, and its two ends are fixedly connected with the rib plate 3-1 and the main body of the movable formwork 3-2 respectively, so The ejector cylinder 1 includes a main ejector cylinder 1-1 and four auxiliary ejector cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com