Production method of frequency domain transmission function shape dynamic tuning optical spectrum wave filter

A spectral filter and transfer function technology, applied in the coupling of optical waveguides, transmission systems, electromagnetic wave transmission systems, etc., can solve the problems of low yield, complexity, lack of flexibility, etc., to reduce insertion loss, simple manufacturing process , the effect of excellent flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

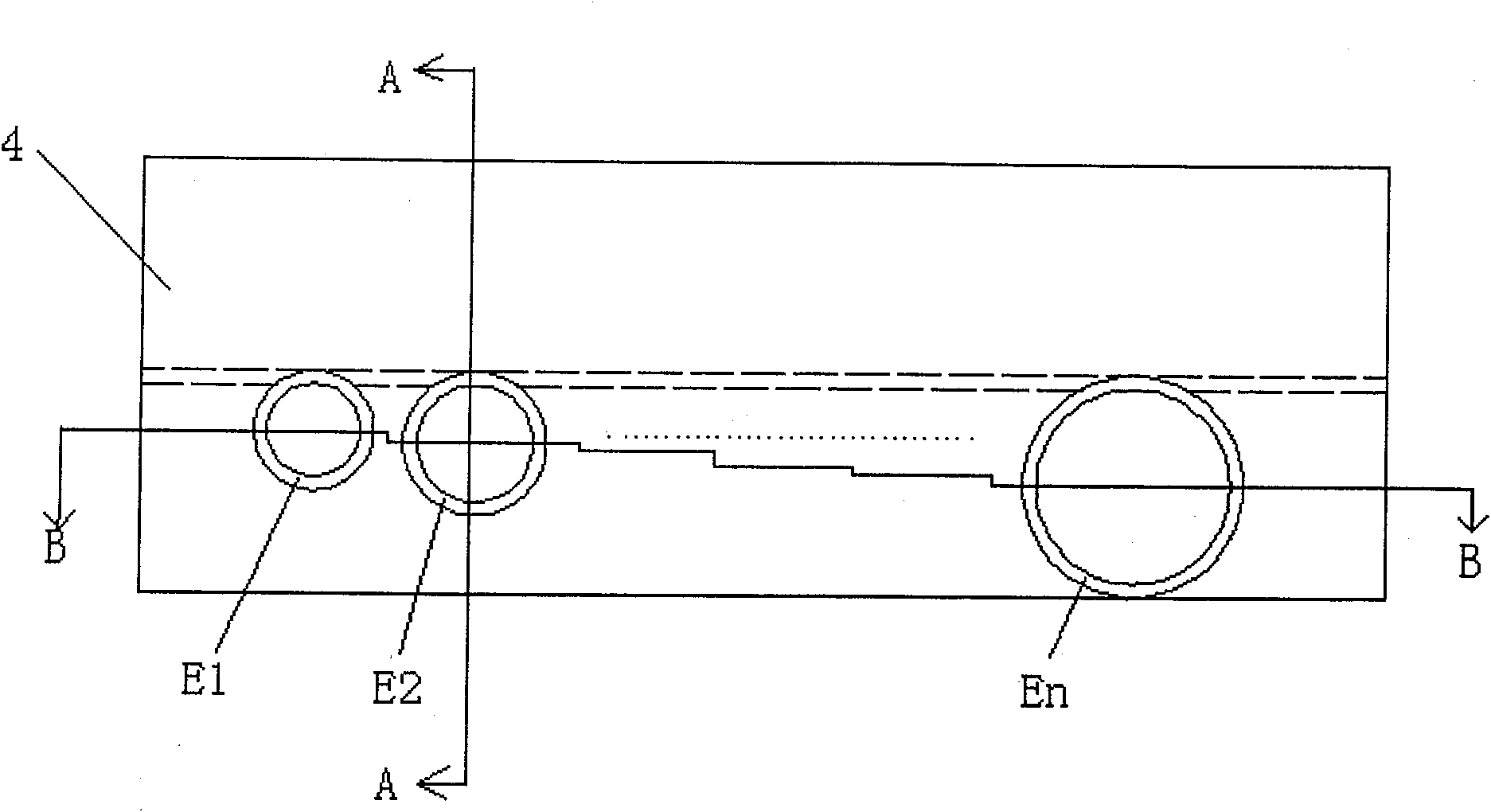

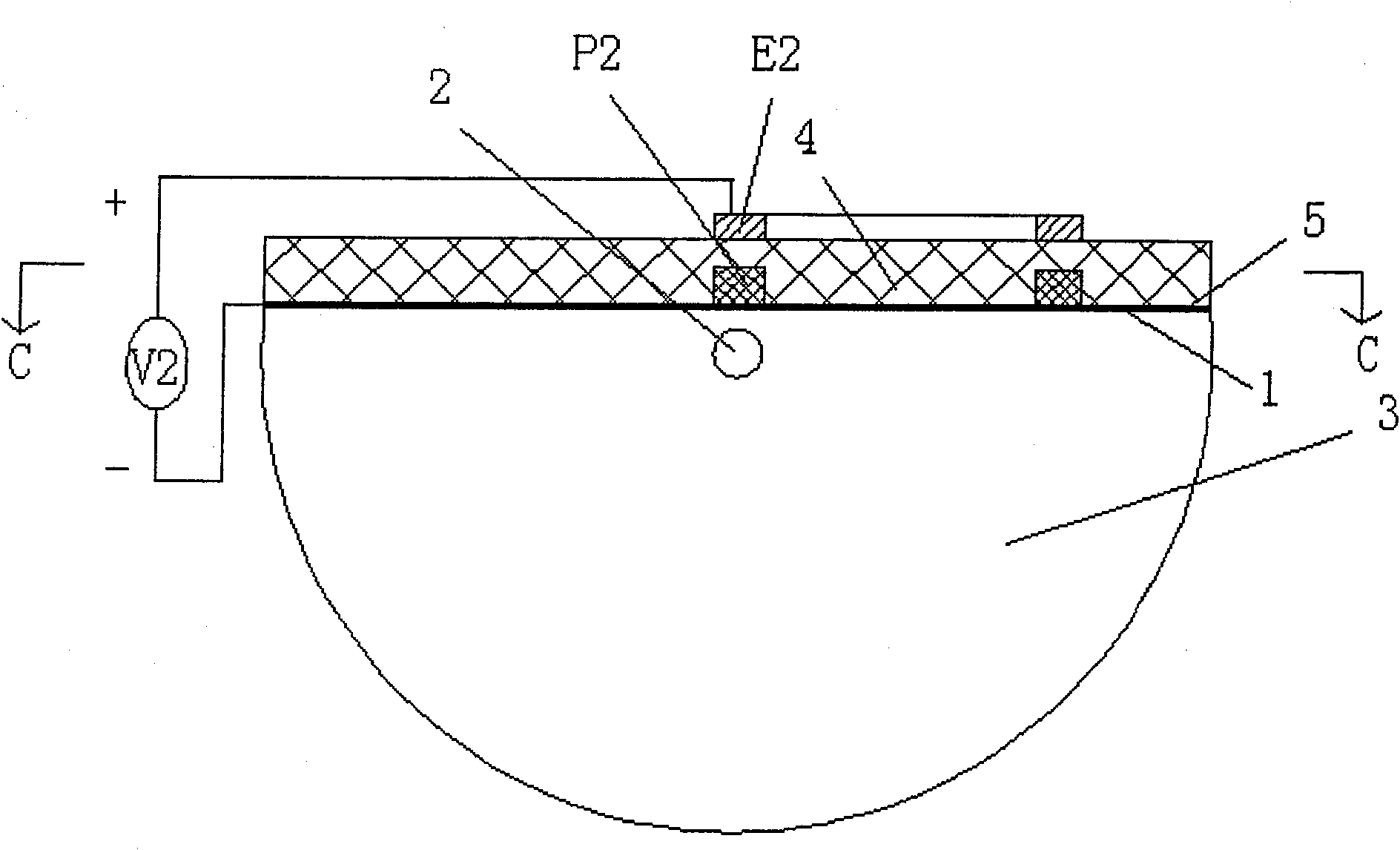

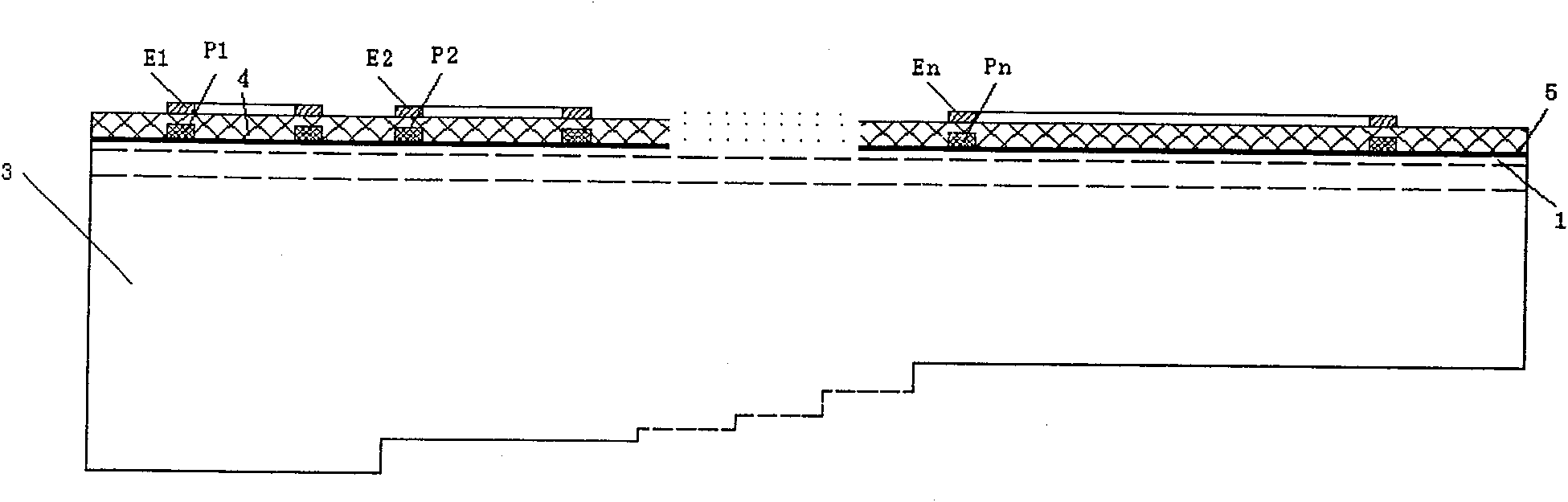

[0033] A method for making a frequency-domain transfer function shape dynamically tuned spectral filter:

[0034] In step 1, a step-type single-mode fiber with a fiber core 2 having a diameter of 1 μm is selected, and the length of the step-type single-mode fiber is 1 m.

[0035] Step 2: Axially grind the middle part of the cladding 3 of the step-type single-mode optical fiber in step 1, the grinding length is 0.5 cm, and grind to the nearest point of 0.5 μm from the fiber core 2, and then polish, and the unground parts at both ends are used as Frequency-domain transfer function shapes for dynamically tuned pigtails of spectral filters.

[0036] In step 3, a layer of ITO electrode 5 is plated on the polished optical fiber axial grinding plane 1 by magnetron sputtering, and the thickness of the ITO electrode is 50 nm.

[0037] Step 4, on the ITO electrode 5, use a spin coater to spin coat a layer of 1 μm thick disperse red 13 / polymethyl methacrylate film with a high electro-op...

Embodiment 2

[0043] A method for making a frequency-domain transfer function shape dynamically tuned spectral filter:

[0044] In step 1, a step-type single-mode fiber with a fiber core 2 having a diameter of 10 μm is selected, and the length of the step-type single-mode fiber is 5 m.

[0045]Step 2: Axially grind the middle part of the cladding 3 of the step-type single-mode optical fiber in step 1. The grinding length is 5 cm, and it is ground to a point 5 μm closest to the fiber core 2, and then polished. The unpolished parts at both ends are used as the frequency domain Transfer function shape for dynamic tuning of spectral filter pigtails.

[0046] In step 3, a layer of ITO electrode 5 is plated on the polished optical fiber axial grinding plane 1 by vacuum evaporation method, and the thickness of the ITO electrode is 80 nm.

[0047] Step 4: Spin-coat a 10 μm-thick disperse red 1 / polycarbonate film with a high electro-optic coefficient on the ITO film using a spin coater, and then et...

Embodiment 3

[0053] A method for making a frequency-domain transfer function shape dynamically tuned spectral filter:

[0054] In step 1, a step-type single-mode fiber with a fiber core 2 having a diameter of 5 μm is selected, and the length of the step-type single-mode fiber is 2.5 m.

[0055] Step 2: Axially grind the middle part of the cladding 3 of the step-type single-mode optical fiber in step 1, the grinding length is 3 cm, and grind to a distance of 2 μm from the nearest point of the optical fiber core 2, and then polish, and the unpolished parts at both ends are used as the frequency Domain transfer function shape for dynamically tunable pigtails of spectral filters.

[0056] In step 3, a layer of ITO electrode 5 is plated on the polished optical fiber axial grinding plane 1 by ion plating method, and the thickness of the ITO electrode is 100 nm.

[0057] Step 4, on the ITO film, apply a layer of 5 μm thick lanthanum-doped lead titanate / polymethyl methacrylate film with high elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com