Multifunctional gas explosion experiment system

A technology of gas explosion and experimental system, which is applied in the field of multifunctional gas explosion experimental system to achieve the effect of reasonable structure, high safety and guaranteed test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

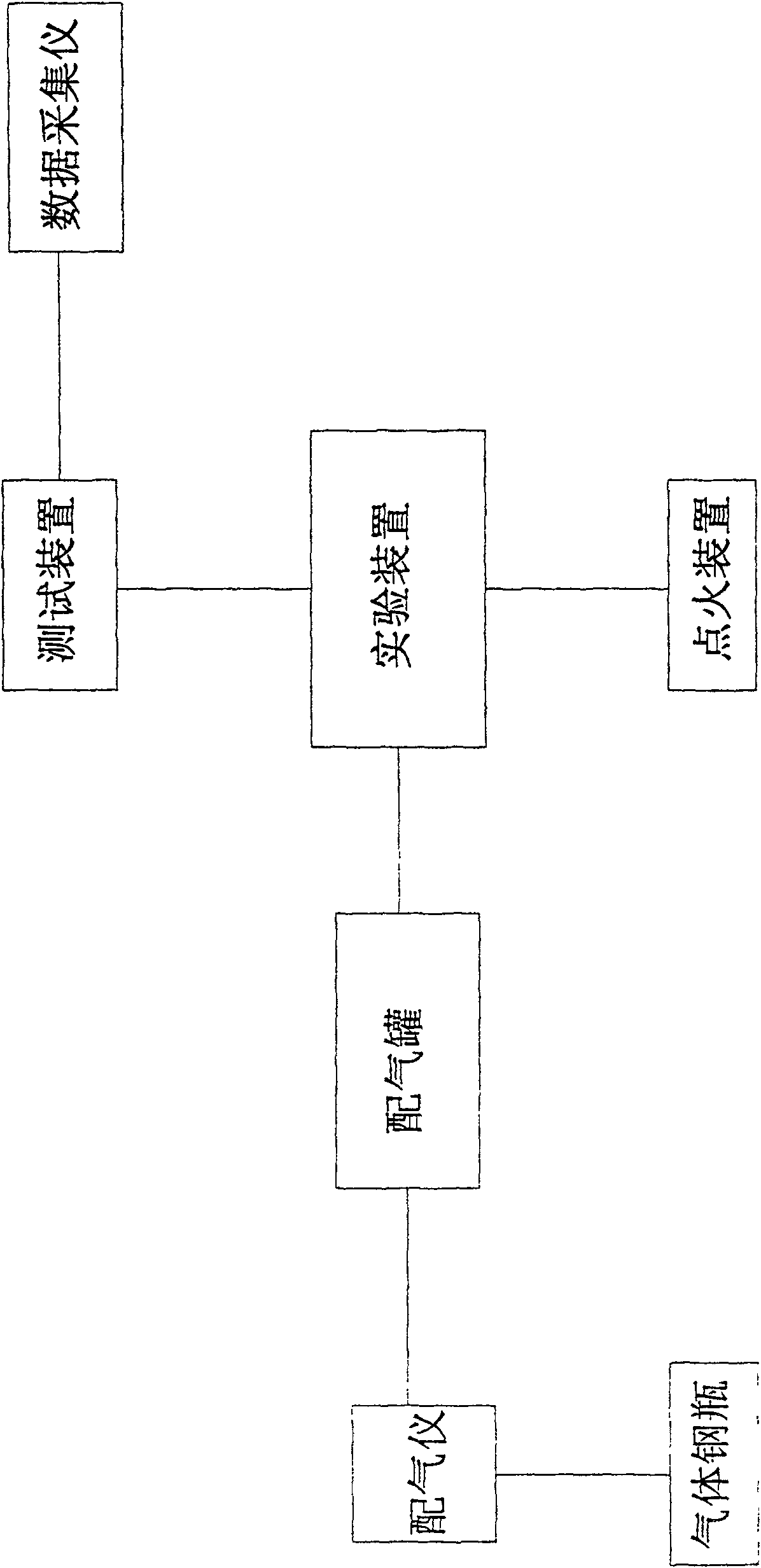

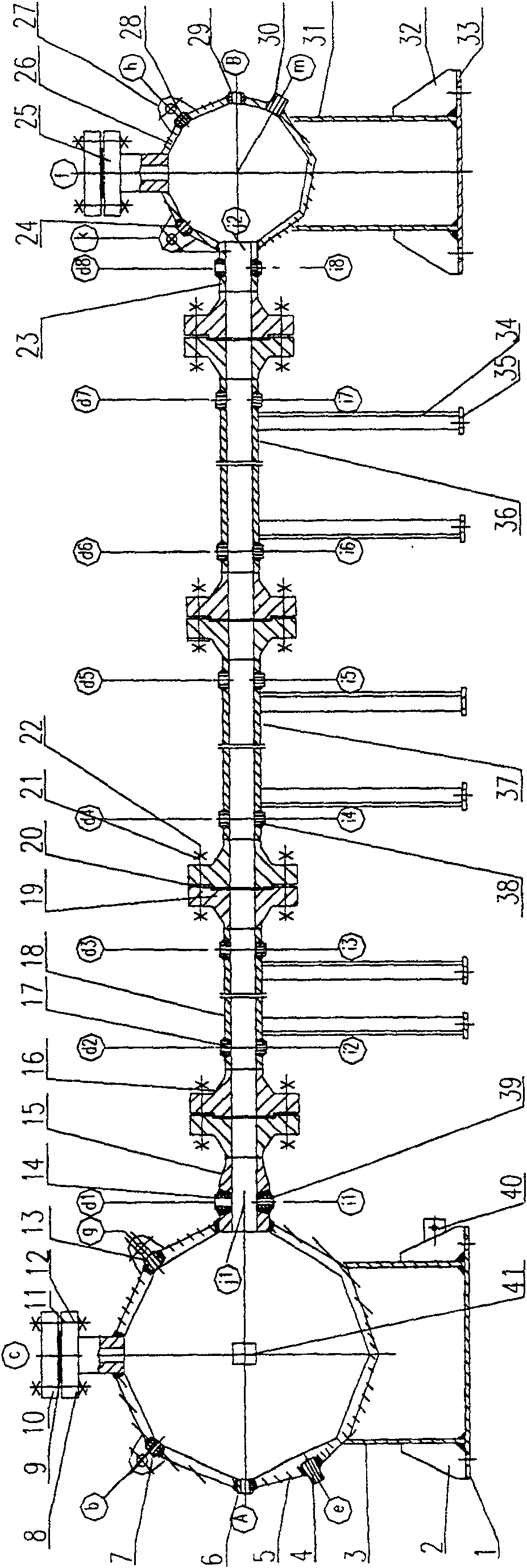

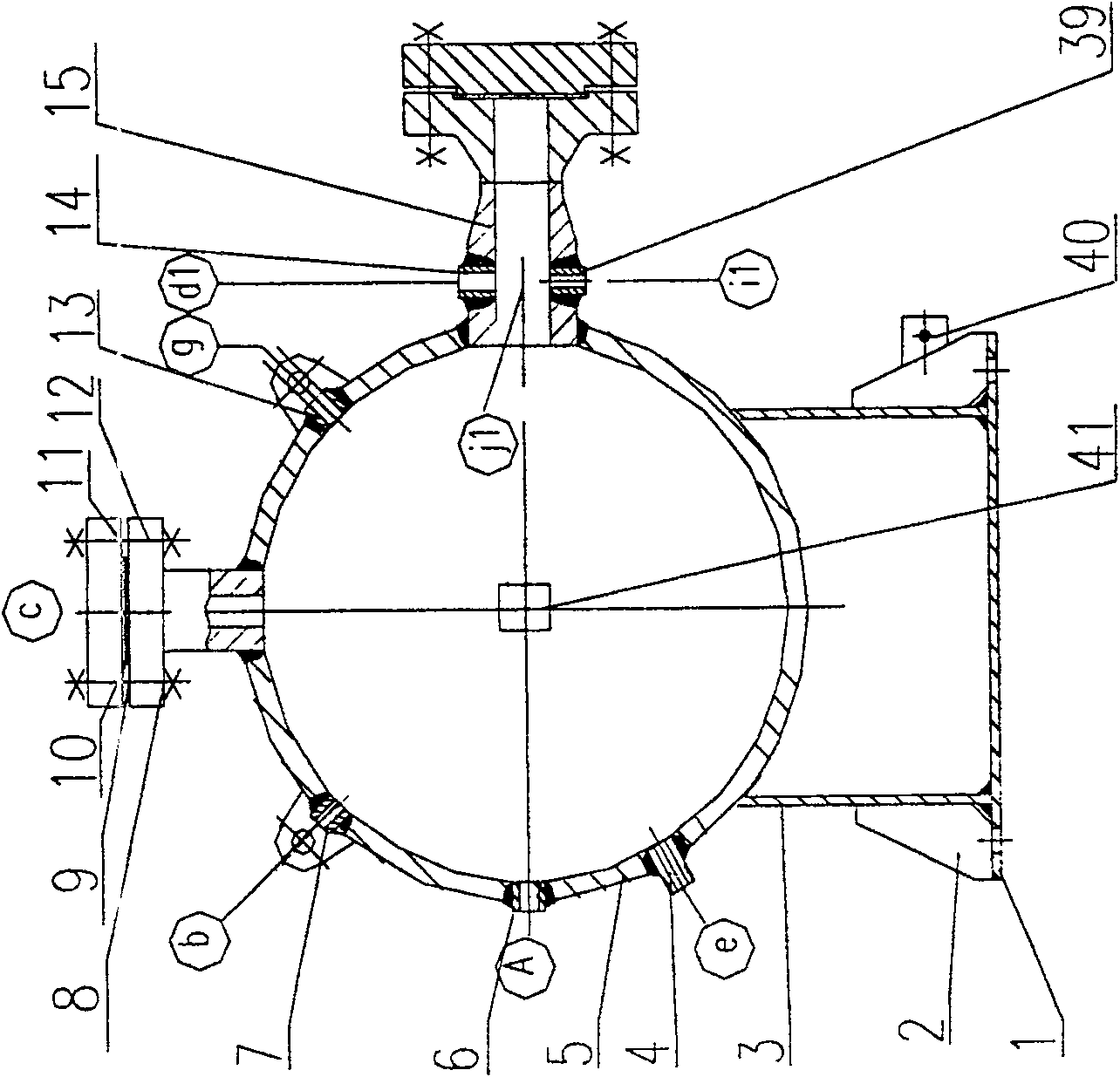

[0031] Refer to attached Figure 1-10 , The multifunctional gas explosion experimental system includes experimental devices, gas distribution devices, ignition devices, test devices, data acquisition and processing parts. The structure of the experimental device includes a large spherical container 5, a pipeline 18, a pipeline 37, a pipeline 36 and a small spherical container 26, and the container, the pipeline and the pipeline are connected by flanges. Install the toothed gasket 10, the rupture disc f, the toothed gasket 10, the flange cover with holes on the flange 8 of the connecting pipe 15 of the large spherical container, or install the toothed gasket 10, the flanged cover 9, and the flange 25 of the connecting pipe 23 of the small spherical container Install toothed pad 10, rupture disc f, toothed pad 10, flange cover with holes, or install toothed pad 10, flange cover 9, and the container flange is closed by stud 11 and nut 12. The bottom of the large spherical contai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com