Solid barbecue charcoal and preparation method thereof

A solid body, barbecue charcoal technology, applied in the field of barbecue fuel, can solve the problems of waste in the processing process, short burning time, limited material source, etc., and achieve the effects of controlling product performance, high practical efficiency and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

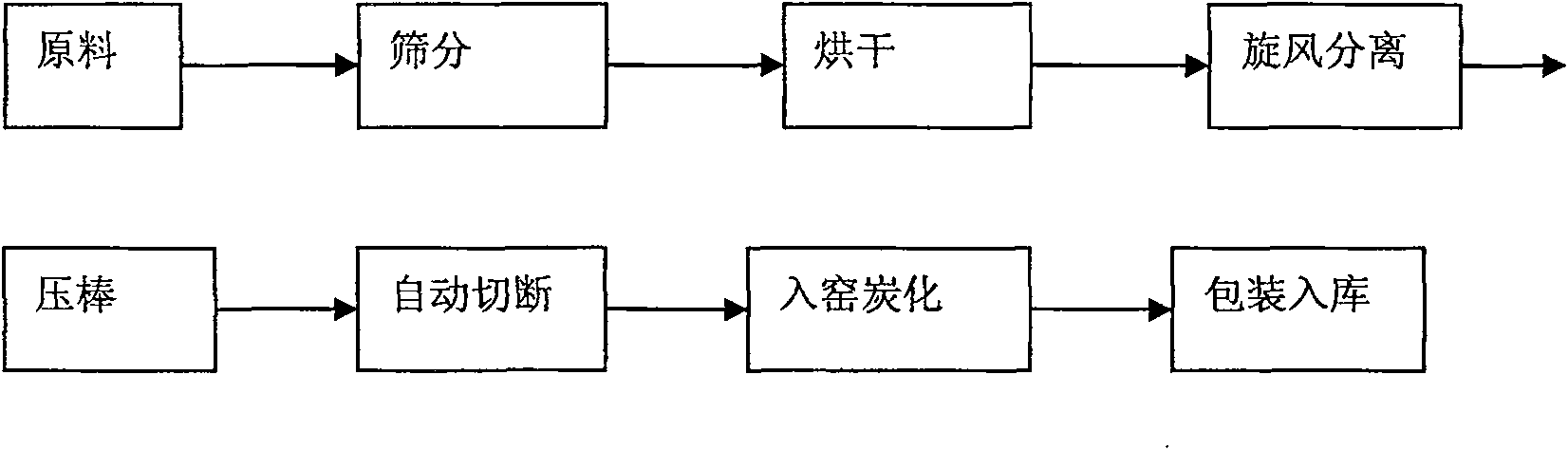

[0017] according to figure 1 The shown process flow produces 100% pure bamboo sawdust solid body barbecue charcoal, and the specific method is:

[0018] The first step, raw material preparation: Recycle the waste bamboo sawdust from various factories, crush and sieve to obtain particles, then transfer the raw material particles to the drying drum or heating furnace for drying, and then enter the cyclone separator for centrifugal drying to Moisture content is 3%;

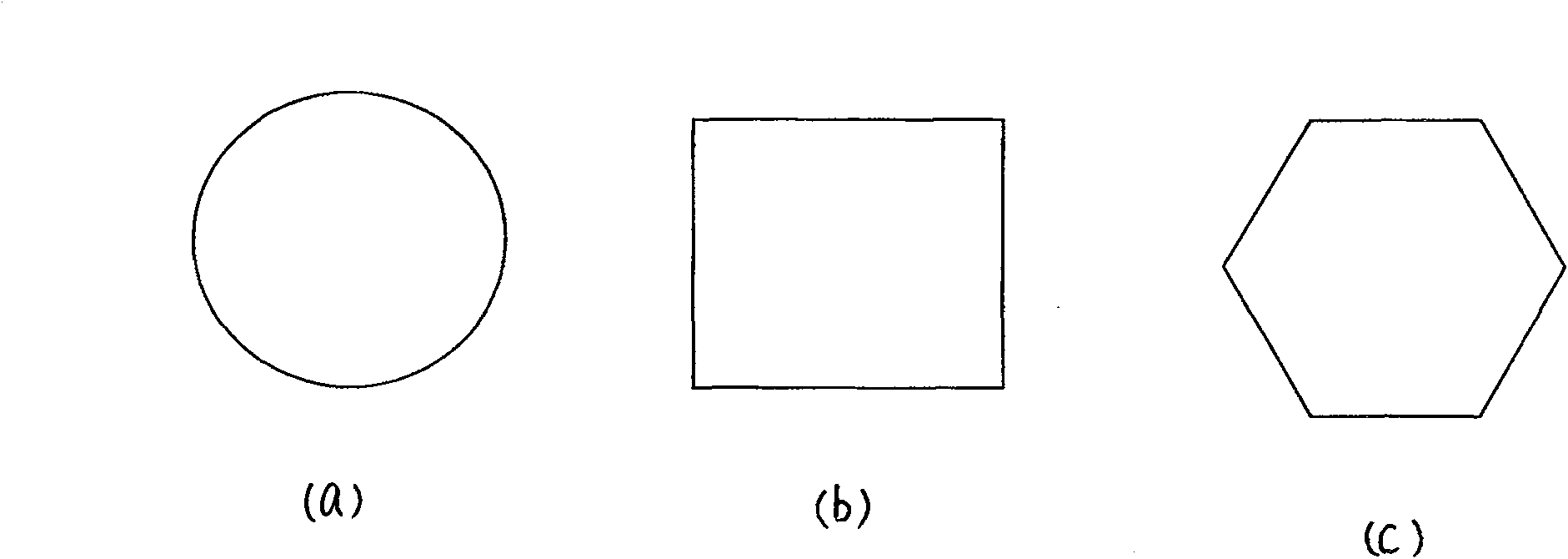

[0019] The second step, rod making: transport the above-mentioned prepared raw material particles to the screw extruder, extrude the rod under pressure to make a square cross-section salary rod, and automatically cut the salary rod according to the length requirement;

[0020] The third step, carbonization: the cut-off fire rods are transported to the charcoal kiln for carbonization. The carbonization is staged high-temperature carbonization. The initial carbonization is 550°C for 2.5 hours, and then the temperature...

Embodiment 2

[0022] according to figure 1 The process flow shown produces 100% pure wood sawdust solid barbecue charcoal, and the specific method is:

[0023] The first step, raw material preparation: recycle waste wood sawdust from various factories, crush and sieve to obtain particles, then transfer the raw material particles to a drying drum or a heating furnace for drying, and then enter a cyclone separator for centrifugal drying to Moisture content is 5%;

[0024] The second step, rod making: transport the above-mentioned prepared raw material particles to the screw extruder, extrude the rod under pressure to make a circular cross-section salary rod, and automatically cut the salary rod according to the length requirement;

[0025] The third step, carbonization: the cut fire rods are transported to the charcoal kiln for carbonization. The carbonization is high-temperature carbonization in stages. The initial carbonization is at 600°C for 2 hours, and then the carbonization is carried...

Embodiment 3

[0027] according to figure 1 The shown process produces bamboo and wood mixed solid body barbecue charcoal,

[0028] The first step: prepare bamboo sawdust and wood sawdust according to the raw material preparation method described in Examples 1 and 2;

[0029] The second step, rod making: the above-mentioned prepared bamboo sawdust and wood sawdust are mixed in a weight ratio of 2:1, and the mixed raw material particles are transported to a screw extruder, and extruded under a 15 kilowatt motor to make rods. Make a hexagonal cross-section salary rod, and automatically cut off the salary rod according to the length requirement;

[0030] The third step, carbonization: the cut-off fire rods are transported to the charcoal kiln for carbonization. The carbonization is high-temperature carbonization in stages. The initial carbonization is 600 ° C for 2 hours, and then the temperature is raised to 1000 ° C for 4.5 hours until it is completely carbonized and then it is out of the ki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com