Dry method sample small bake oven

A drying method and oven technology, applied in drying, dryer, leather drying and other directions, can solve the problems of difficult temperature uniformity, low blower power, uneven temperature in the box, etc., to achieve accurate sample position and improve work efficiency , the effect of reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

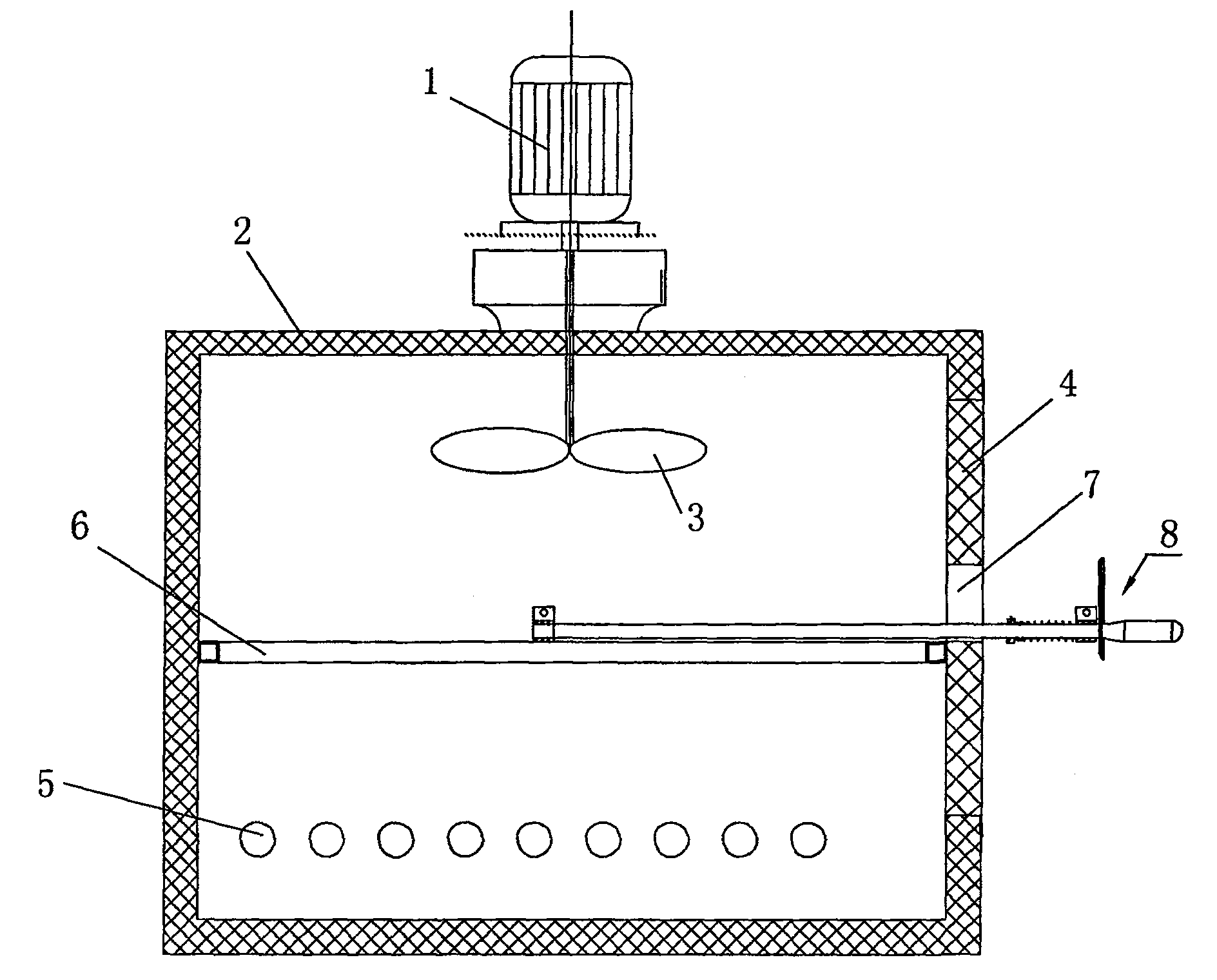

[0027] see figure 1 , in this embodiment, fan 1 is set to be located at the top of box body 2, and fan blade 3 is suspended above the sample; box body 1 and door body 4 are set as an integral form, and the interlayer is made of stainless steel, and the interlayer is made of insulating material Filling, this structure has good thermal insulation performance; a horizontal support 6 is set above the heating tube 5 in the box, and a sample delivery hole 7 is opened on the door body 4 at the height of the horizontal support 6, and the sample rack 8 can send samples by itself. The hole 7 is inserted, and the horizontal support 6 is used as a guide rail, and can be kept on the horizontal support 6. The tail of the sample rack 8 is fixedly connected with a sealing plate 81 that can block the sample delivery hole 7, and the outside of the sealing plate 81 Solid connection operating handle 82.

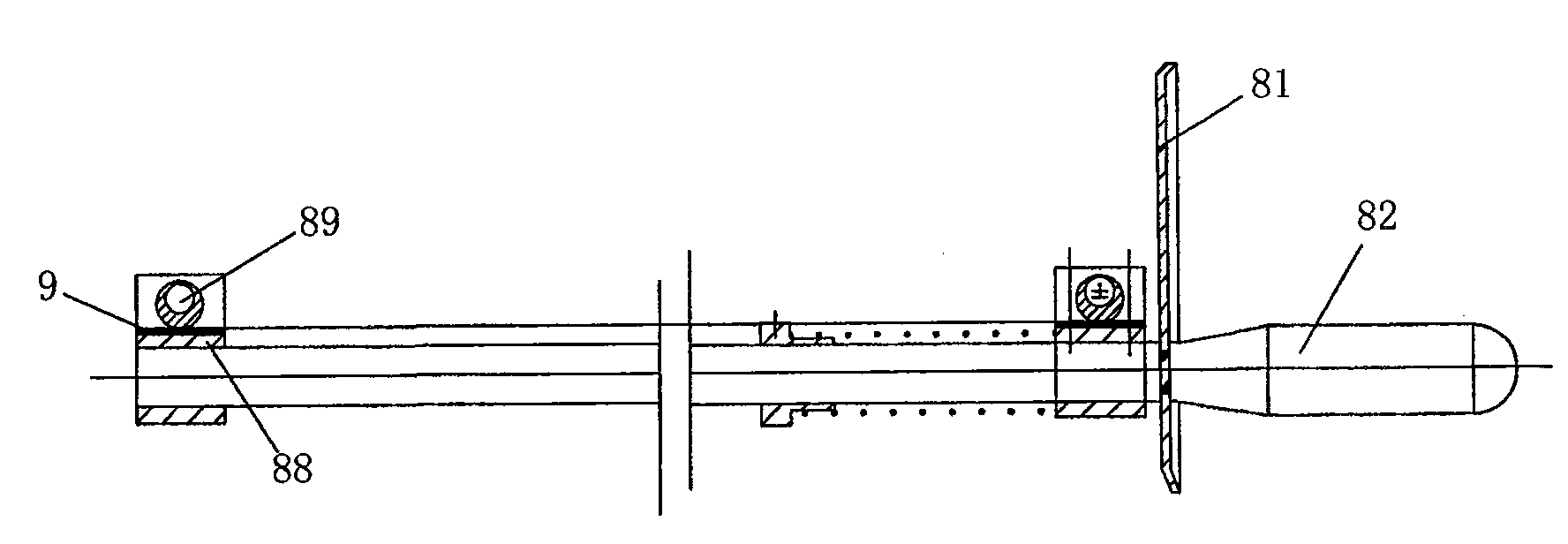

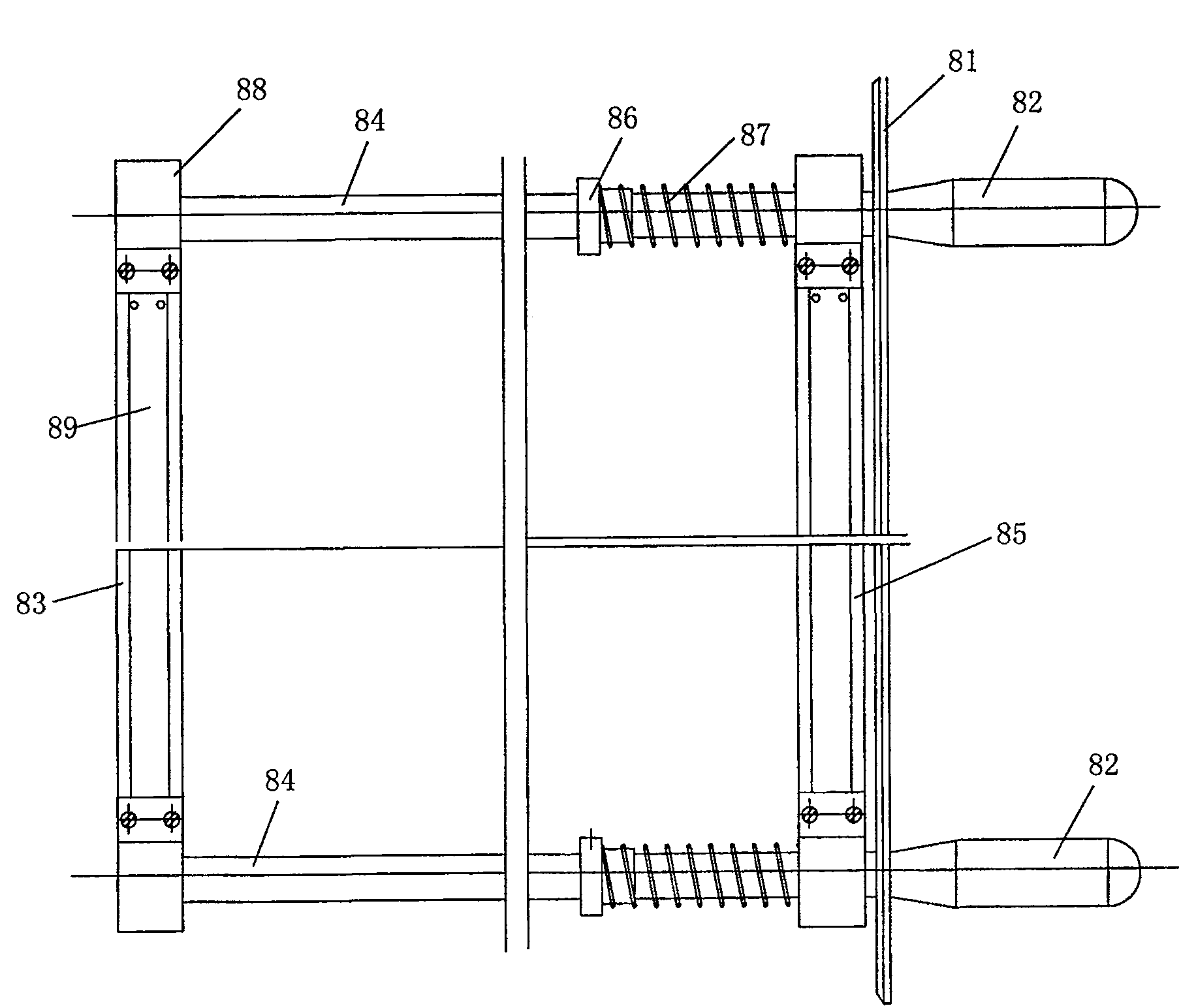

[0028] see figure 2 , image 3 , in the present embodiment, the sample holder 8 is a pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com