Slurry feeding device in front of stove burning petroleum water coke slurry

A technology of industrial boilers and water coke slurry, which is applied in the petroleum industry, combustion methods, liquid fuel supply/distribution, etc., can solve problems such as easy ash accumulation, pipeline blockage, and difficult to burn out, so as to prevent hard precipitation and blockage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

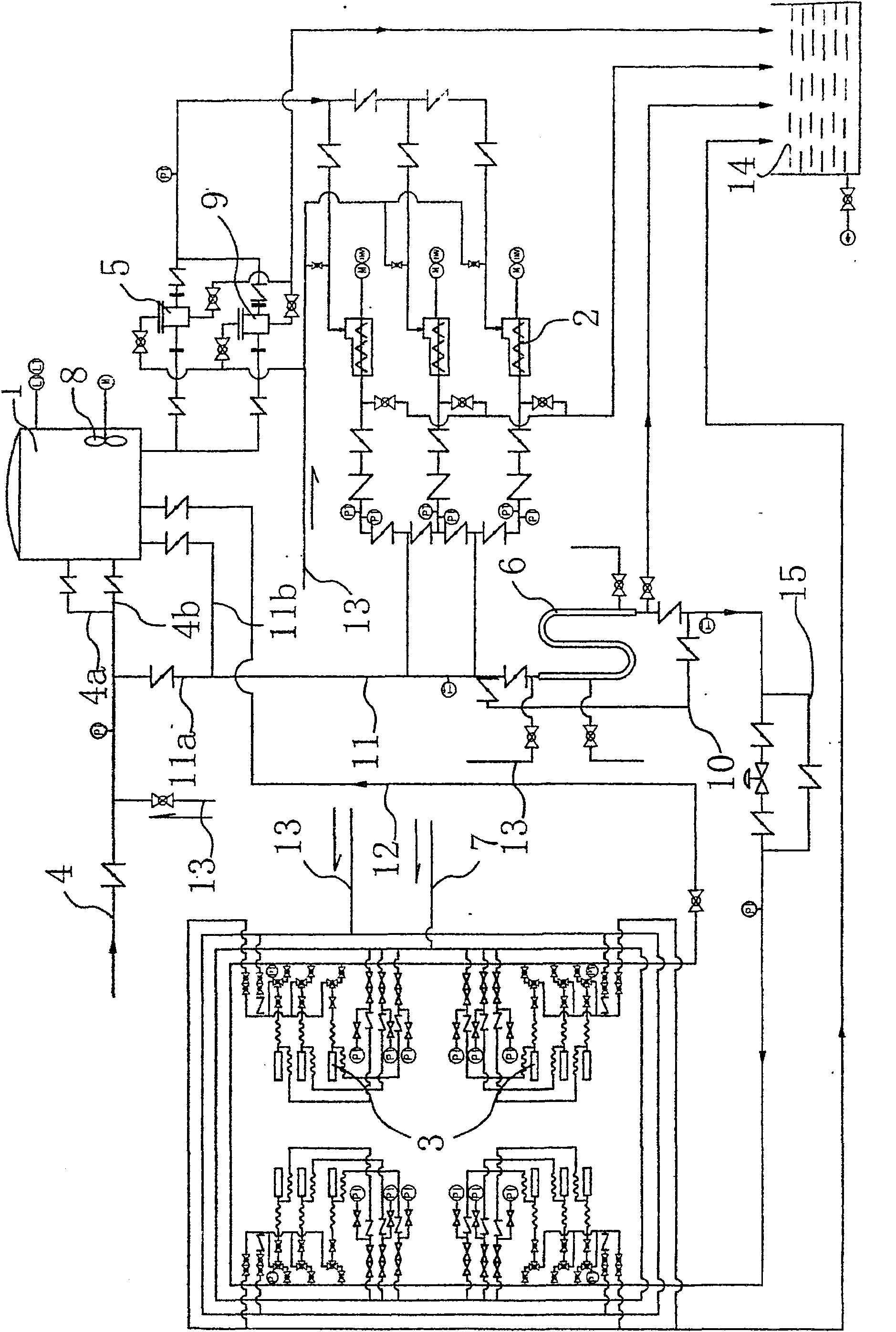

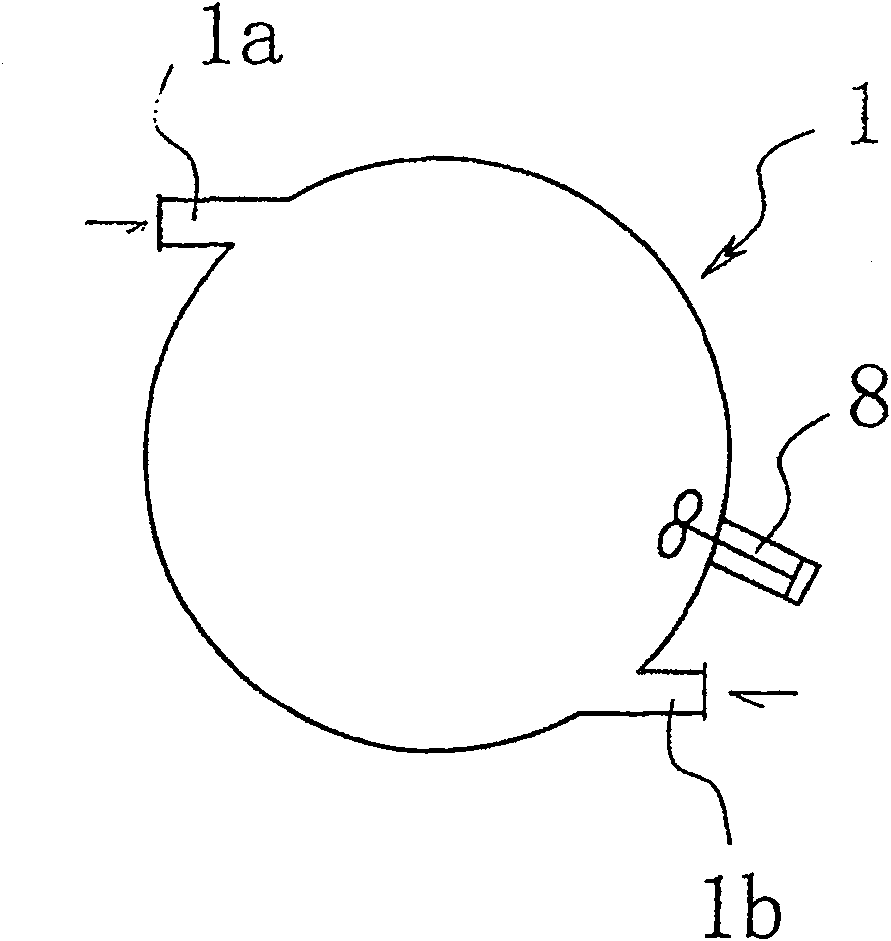

[0025] According to the first embodiment of the present invention, the front-furnace slurry supply device of an industrial boiler burning petroleum water coke slurry is such as figure 1 As shown, this is a specific embodiment of a slurry supply device for a power station boiler that uses petroleum water coke slurry, which includes: daily slurry storage tank 1, three slurry supply pumps 2, and four sets of twelve petroleum water coke Slurry spray gun 3. The three slurry supply pumps 2 in this embodiment all use a three-stage variable frequency adjustment screw pump, which can be used to adjust the output pressure of the slurry supply pump, that is, the slurry pressure entering the petroleum water coke slurry spray gun 3 to meet the requirements of the power station boiler load change Generally, two of the three slurry supply pumps 2 can be used for normal operation, and the other can be used as a backup to ensure continuous operation. The cross-sectional structure of the daily slu...

Embodiment 2

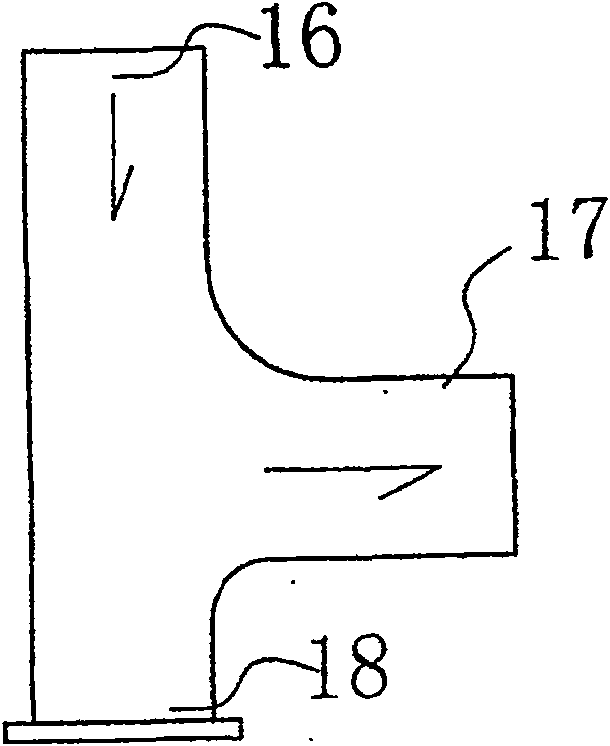

[0028] According to the second embodiment of the present invention, the front-furnace slurry supply device of an industrial boiler that burns petroleum water coke slurry is an example of technical improvement of the slurry supply device of a power station boiler that uses petroleum water coke slurry. Compared with the embodiment, the difference is that the low elbow of all pipelines (that is, the 90-degree right-angle elbow in the long low-level pipeline) is replaced by a three-way pipe. The structure of the low-level elbow is as follows: image 3 Shown. The petroleum water coke slurry enters from one of the straight inlets 16 of the three-way pipe and flows out from the side outlet 17. The straight outlet at the other end of the three-way pipe is sealed with a bolt or other detachable device to seal the blind plate 18. When the pipe is blocked, The blind plate 18 can be opened to facilitate cleaning and dredging of the pipeline.

Embodiment 3

[0030] According to the third embodiment of the present invention, the slurry supply device in front of the furnace of an industrial boiler that burns petroleum water coke slurry, and the specific embodiment of the slurry supply device of a power station boiler that uses petroleum water coke slurry is similar to the first implementation described above. Compared with the method, there are also multiple sets of clean water flushing pipelines 13 to separately perform the slurry supply pump 2, the petroleum water coke slurry spray gun 3, the slurry supply pipeline 4, the filter 5, the preheater 6 and the backup filter 9. rinse. Among them, the slurry supply pump 2, the filter 5, and the backup filter 9 can be provided with a common set of clean water flushing pipeline 13, and the three slurry supply pumps 2, the filter 5, and the backup filter 9 can be separately controlled by the pipeline valve. The slurry supply pipeline 4 can be provided with a separate set of clean water flushing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com