Ring fine spinning machine machinery centralization type compact spinning apparatus

A technology of spinning machine and machinery, applied in spinning machine, textile and papermaking, drafting equipment, etc. problems, to achieve the effect of improving the aggregation effect and improving the performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

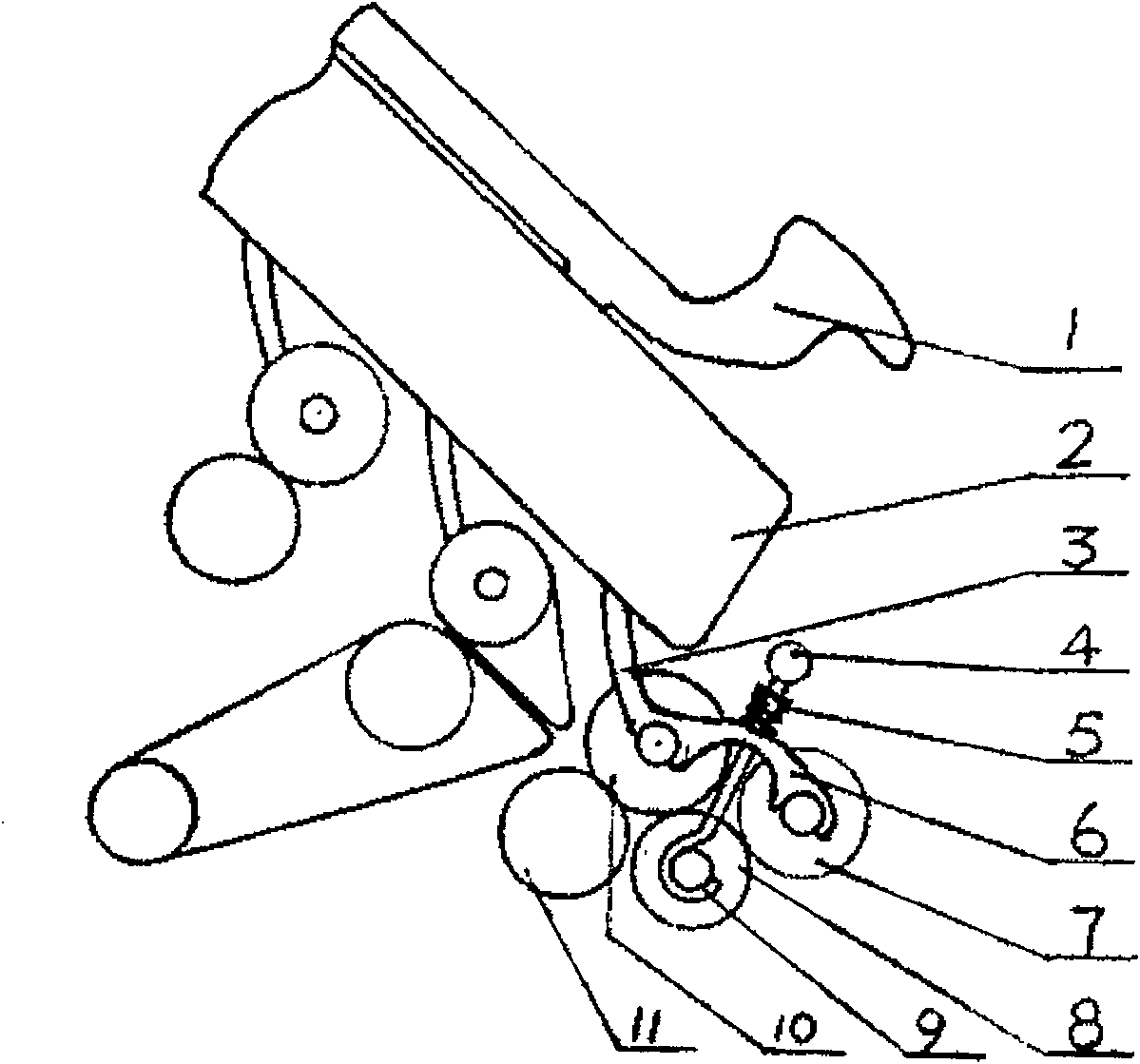

[0016] Embodiment of the invention is described as follows in conjunction with accompanying drawing:

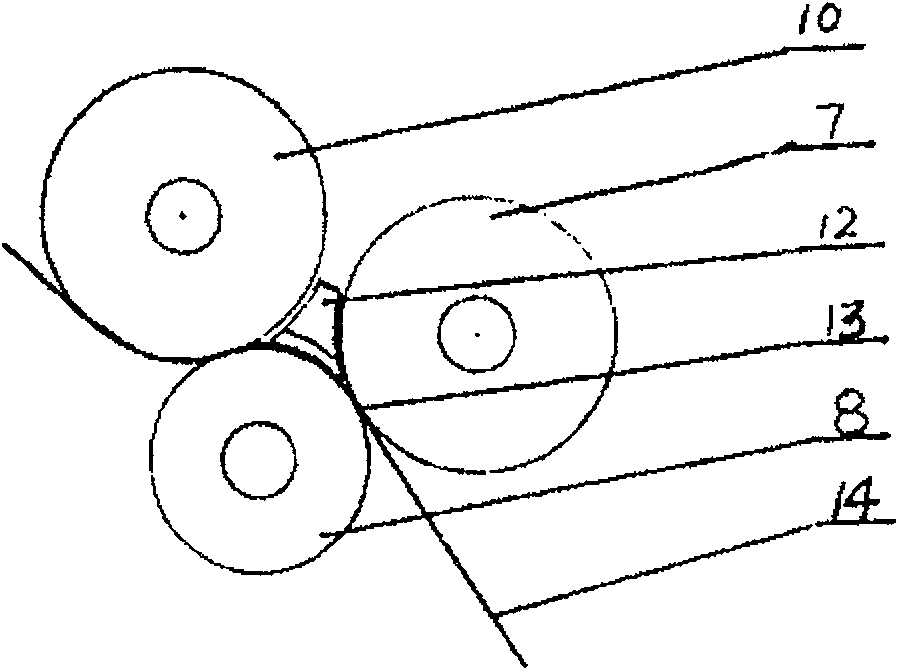

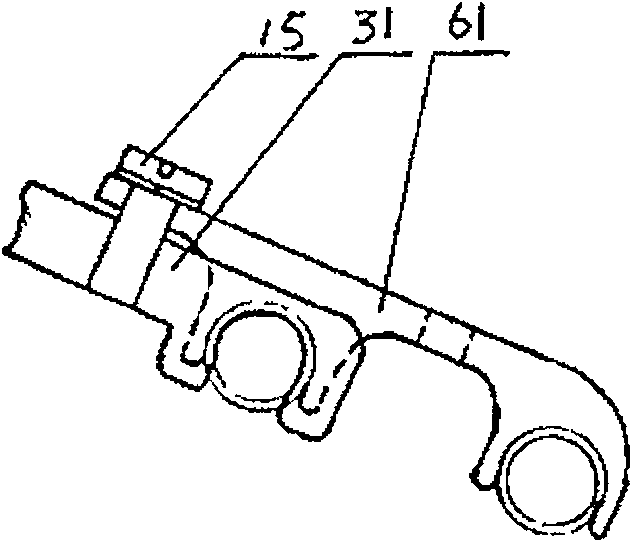

[0017] exist figure 1 and figure 2 Among them, the accumulating roller 8 is located downstream of the front roller nip extension line, the accumulating bracket 6 is combined with the front paw 3 of the front top roller, the anti-twisting cot roller 7 is located at the front and upper part of the accumulating roller 8, and the front cot roller 10 and the anti-twisting roller on the accumulating roller 8 The accumulating area between the top rollers 7 places an accumulator 12 .

[0018] The accumulating roller 8 is a rigid roller with a pair of spindles. The axis core of the accumulating roller 8 is pulled up by the pressurized structure to position and press the front top roller 10 and the anti-twisting top roller 7 tightly. The accumulating roller 8 and the anti-twisting top roller 7 forms the twist blocking jaw 13, and the gathering roller 8 and the front top roller 10 fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com