Concave copper sheet for being pasted to slideway and pasting tool assembly

A concave, copper sheet technology, applied in the direction of connecting components, material gluing, mechanical equipment, etc., can solve the problems of reducing social and economic benefits, shortening service life, accelerating surface damage of slideways, etc., to improve social and economic benefits, reduce emission cost, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing:

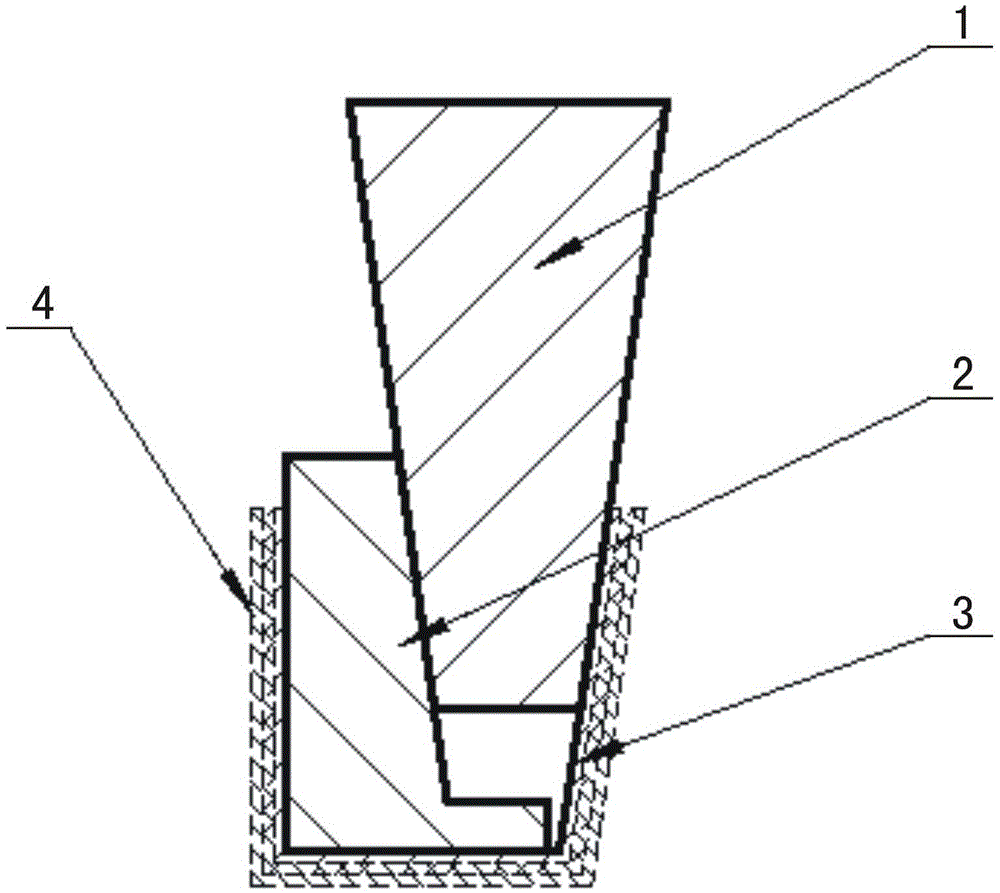

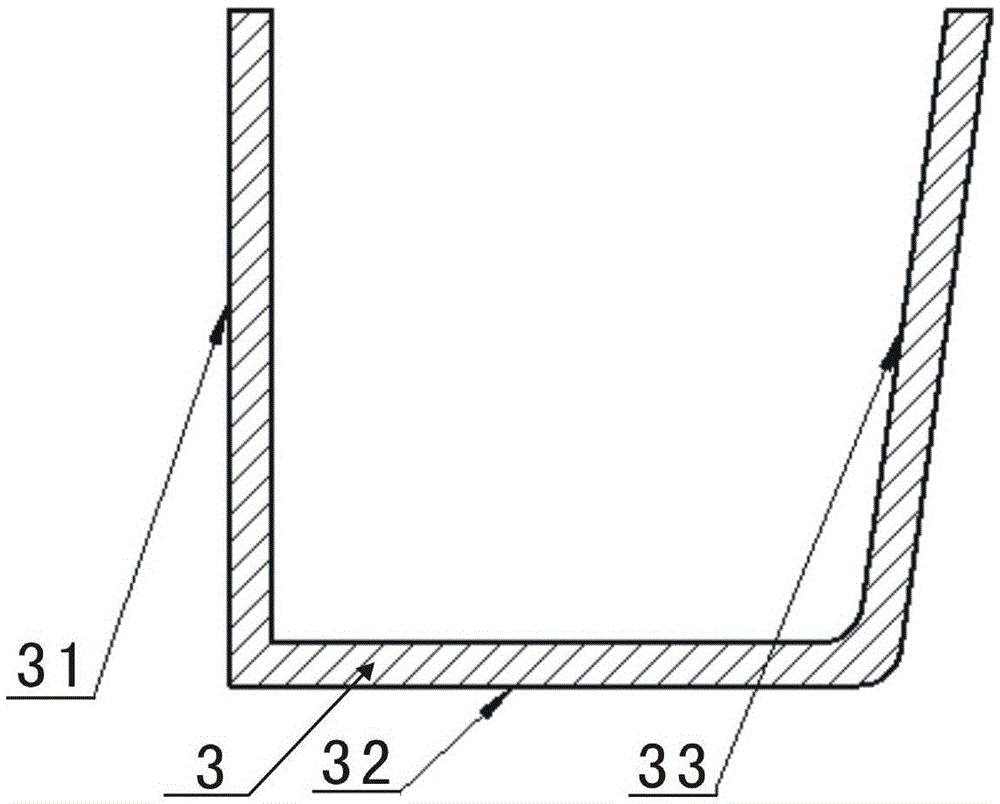

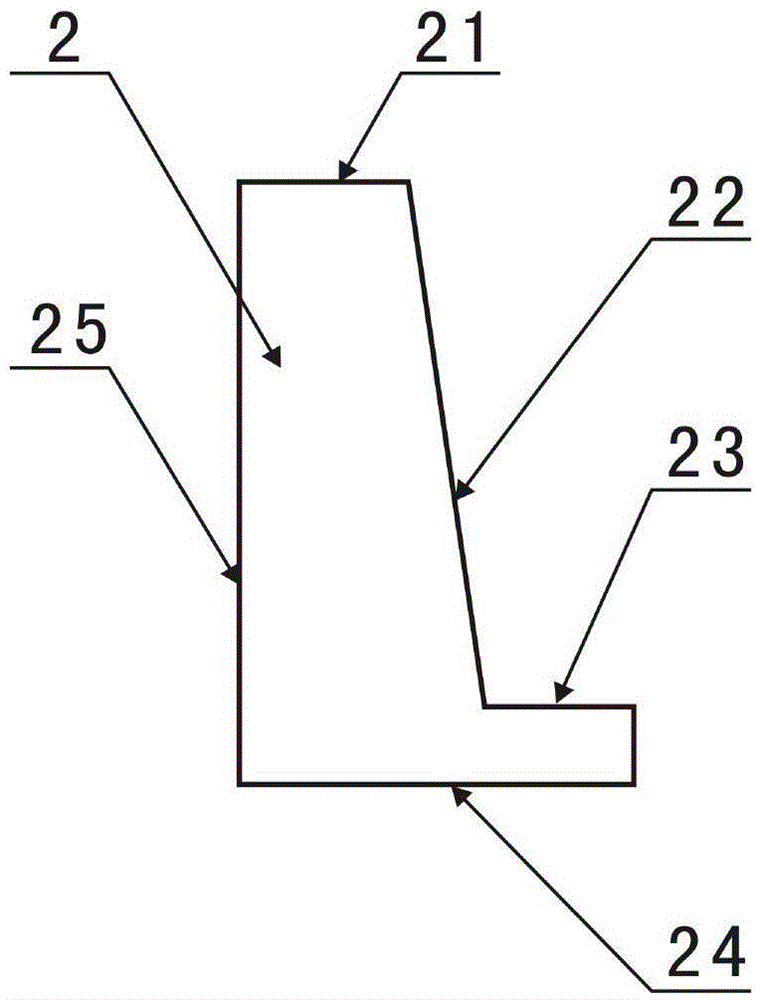

[0019] like Figure 1-Figure 6 Shown, the concave copper sheet 3 that is used for sticking slideway described in the present invention is used for bonding on the concave groove surface of certain object slideway, and concave copper sheet 3 is made of a bottom plate 32, a vertical side plate 31 and a The inclined side plate 33 is integrally formed, and the inner inclined surface of the inclined side plate 33 of the concave copper sheet 3 is gradually inclined outward from the bottom to the top. The adhesive tooling assembly for pasting the slideway according to the present invention includes a pressing wedge 1 and a pressing block 2. The pressure wedge 1 includes a top plane 11, a bottom plane 13 and two symmetrical inclined sides 12. The two symmetrical inclined sides 12 of the pressure wedge 1 gradually slope outward from bottom to top. The pressure block 2 includes a top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com