Measurement method of planeness based on image processing and pattern recognizing

An image recognition and image processing technology, applied in the field of measurement and control, can solve problems such as affecting the allowable driving speed of the vehicle, stumbling easily, and affecting the appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

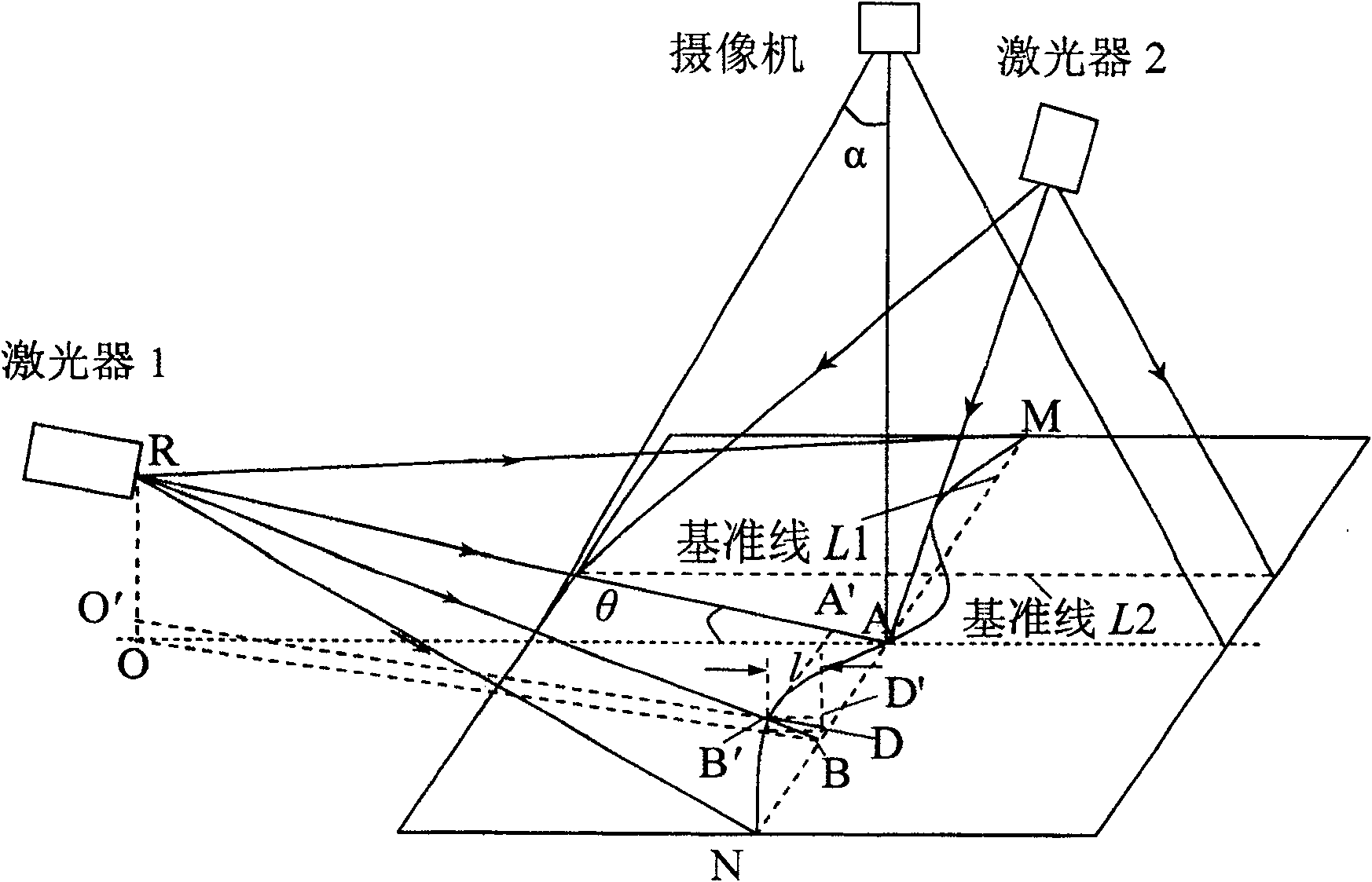

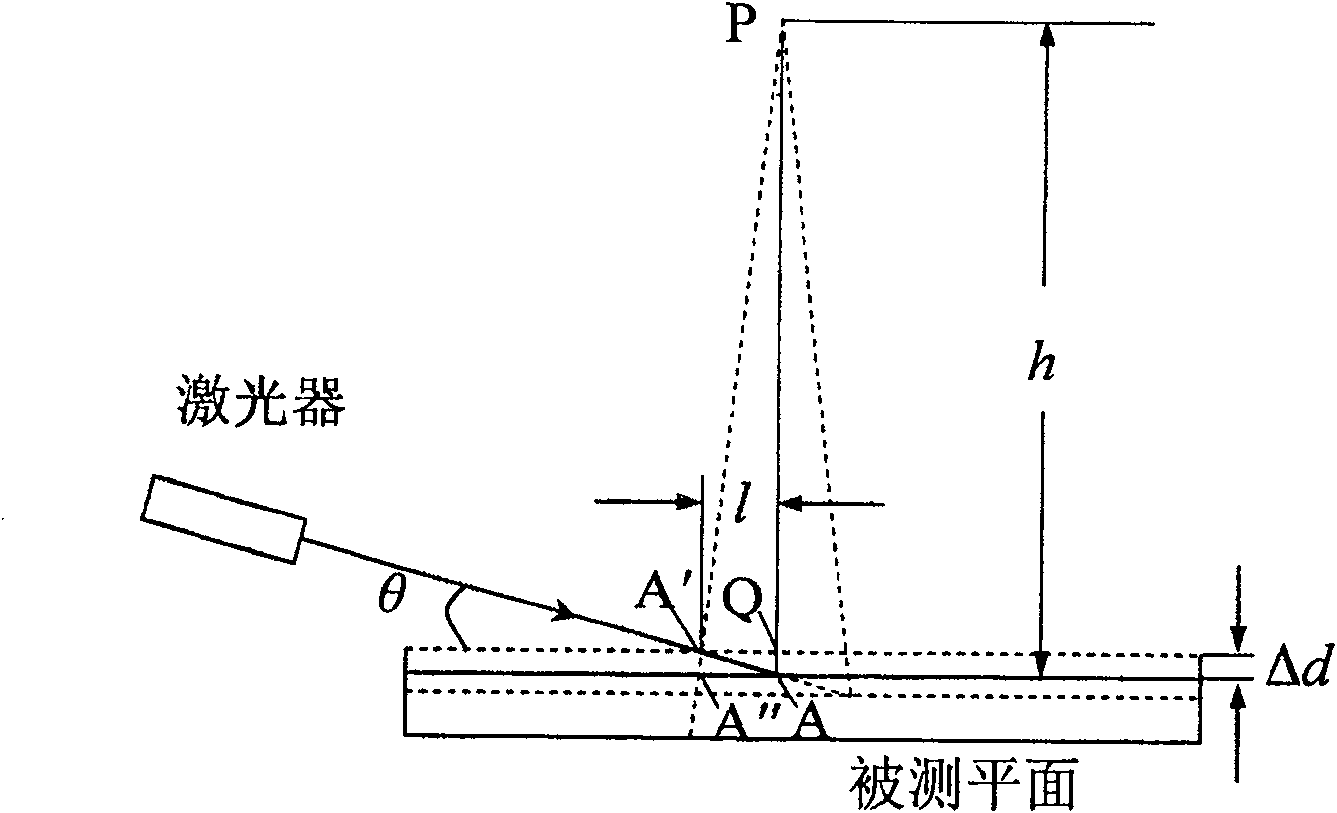

[0012] The present invention analyzes the flatness of the plane by utilizing the geometrical relationship between the degree of deviation of some pixel positions in the image from the reference position and the flatness of the plane.

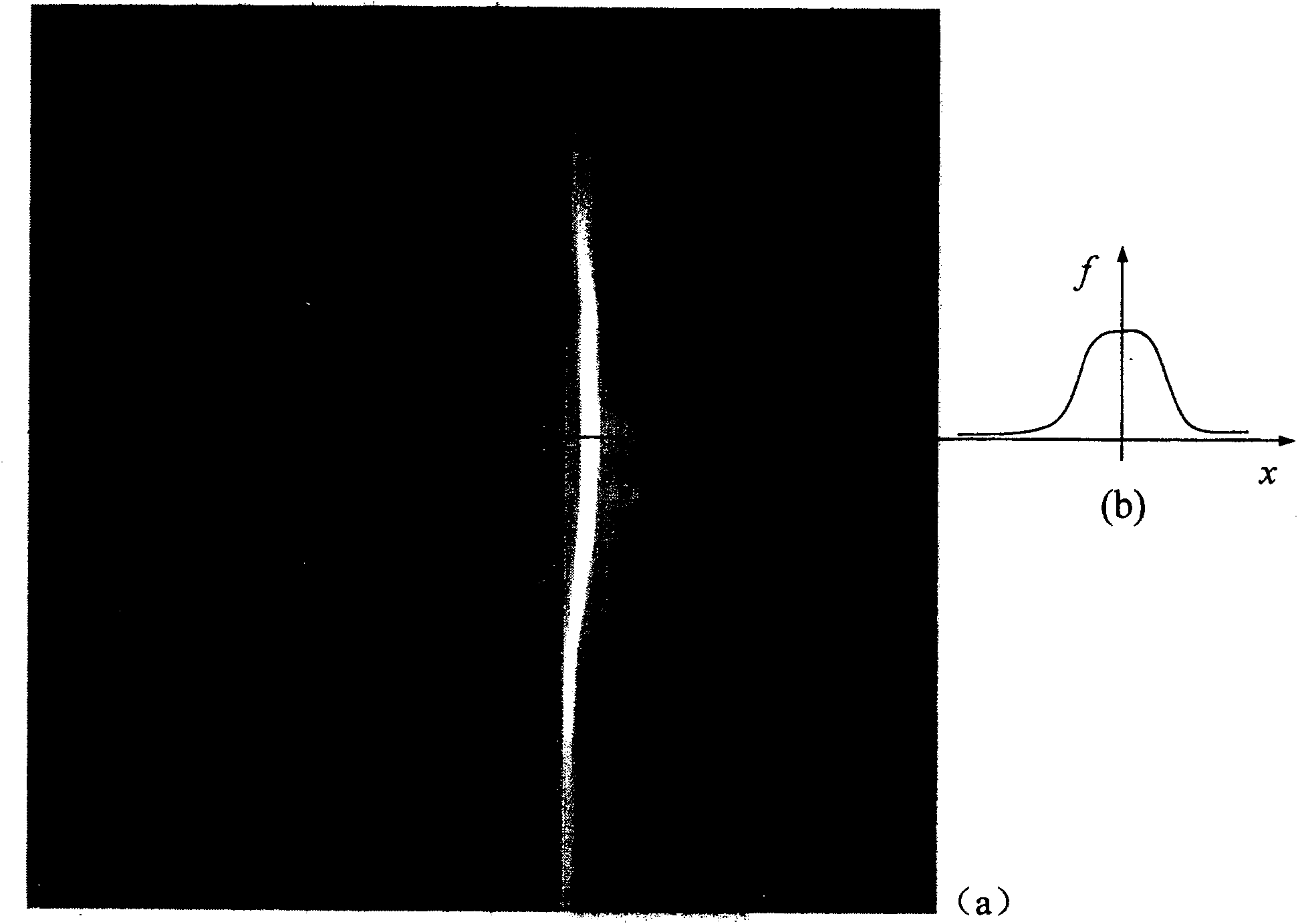

[0013] The unevenness of the plane will lead to deformation of the projection of the inline laser on the measured object. The degree of this deformation depends on the unevenness of the plane. Therefore, there is a correspondence between the unevenness of the plane and the deformation of the inline laser. relation. Through geometric analysis, this corresponding relationship is obtained, and the flatness in the direction of the straight line of the plane can be deduced from the distance between the pixel and the corresponding straight line obtained in the image recognition.

[0014] Specifically include the following steps:

[0015] 1) First, the inline laser is installed in the east-west direction and north-south direction of the plane accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com