Method for preparing silicane fecula

A starch and silane technology, which is applied in the field of silane starch preparation, can solve the problems of uneven contact of modifiers, unstable product quality, high post-processing costs, etc., and achieve uniform product modification, improved dispersibility, and short reaction time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

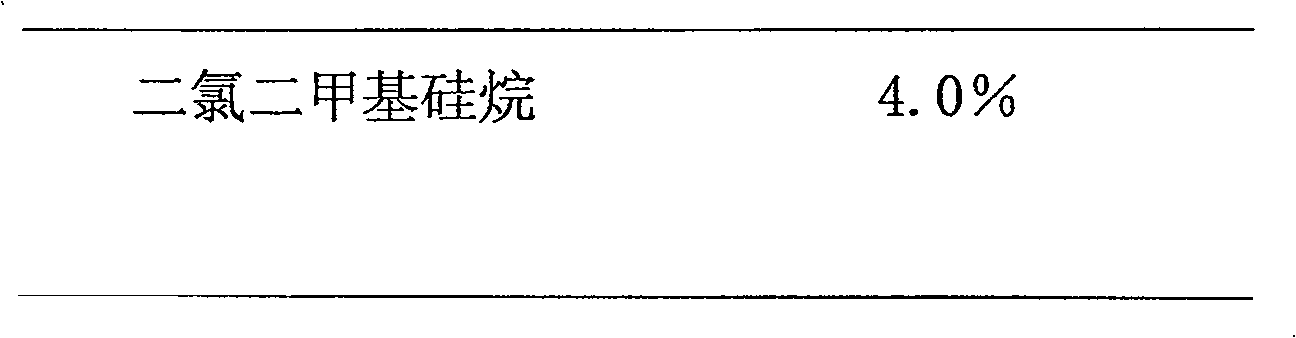

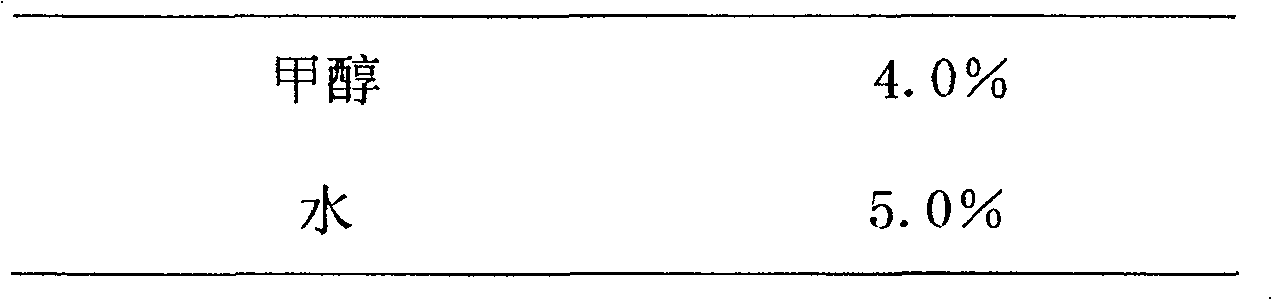

[0014] The ratio of raw materials is based on the quality of starch, and the percentages of other raw materials relative to the quality of starch are as follows:

[0015]

[0016]

[0017] The preparation method is as follows:

[0018] Put a certain amount of starch into the fluidized bed, and dry the starch with air at 80-110°C as the drying medium or fluidized medium for 5-20 minutes. After the water content of the starch drops below 5%, switch the temperature to 130°C for nitrogen. After the carrier gas or fluidizing gas is purged for 0.5 to 1 minute, a certain amount of methanol and water are sent to the mixer with a metering pump, so that they are gasified and mixed with nitrogen and enter the fluidized bed to contact with starch. The conveying speed of methanol and water must be maintained until the reaction of the whole formulation amount of dichlorodimethylsilane is completed. After the vaporized methanol and water vapor contact the starch for 2 minutes, use a m...

Embodiment 2

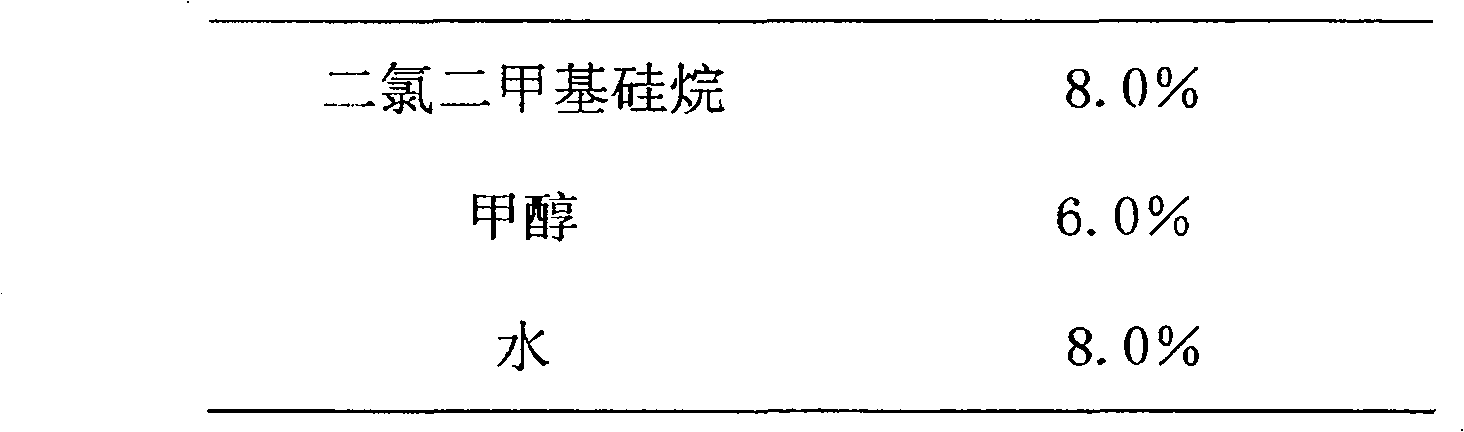

[0020] The ratio of raw materials is based on the quality of starch, and the percentages of other raw materials relative to the quality of starch are as follows:

[0021]

[0022] The preparation method is as follows:

[0023] Put a certain amount of starch into the fluidized bed, use air at 80-110°C as the drying medium or fluidized medium to dry the starch for 5-20 minutes, and after the water content of the starch drops below 5%, switch the temperature to 120°C for nitrogen. After the carrier gas or fluidizing gas is purged for 0.5 to 1 minute, a certain amount of methanol and water are sent to the mixer with a metering pump, so that they are gasified and mixed with nitrogen and enter the fluidized bed to contact with starch. The conveying speed of methanol and water must be maintained until the reaction of the whole formulation amount of dichlorodimethylsilane is completed. After the gasified methanol and water contact the starch for 2 minutes, start to send the dichlo...

Embodiment 3

[0025] The ratio of raw materials is based on the quality of starch, and the percentages of other raw materials relative to the quality of starch are as follows:

[0026]

[0027] The preparation method is as follows:

[0028] Put a certain amount of starch into the fluidized bed, use air at 80-110°C as the drying medium or fluidized medium to dry the starch for 5-20 minutes, and after the water content of the starch drops below 5%, switch the temperature to 110°C for nitrogen. After the carrier gas or fluidizing gas is purged for 0.5 to 1 minute, a certain amount of methanol and water are sent to the mixer with a metering pump, so that they are gasified and mixed with nitrogen and enter the fluidized bed to contact with starch. The conveying speed of methanol and water must be maintained until the reaction of the whole formulation amount of dichlorodimethylsilane is completed. After the vaporized methanol and water contact the starch for 2 minutes, start to send dichlorod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com