Producing method of soft joint for cross-linked polyethylene cable

A cross-linked polyethylene and soft joint technology, which is used in cable joints, equipment for connecting/terminating cables, etc., can solve the problem that the die casting joint technology has not been really used, the construction period is long, and the operation skills of engineering and technical personnel High level requirements, etc., to achieve the effect of eliminating creepage effect defects, eliminating void defects, and eliminating air gap defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

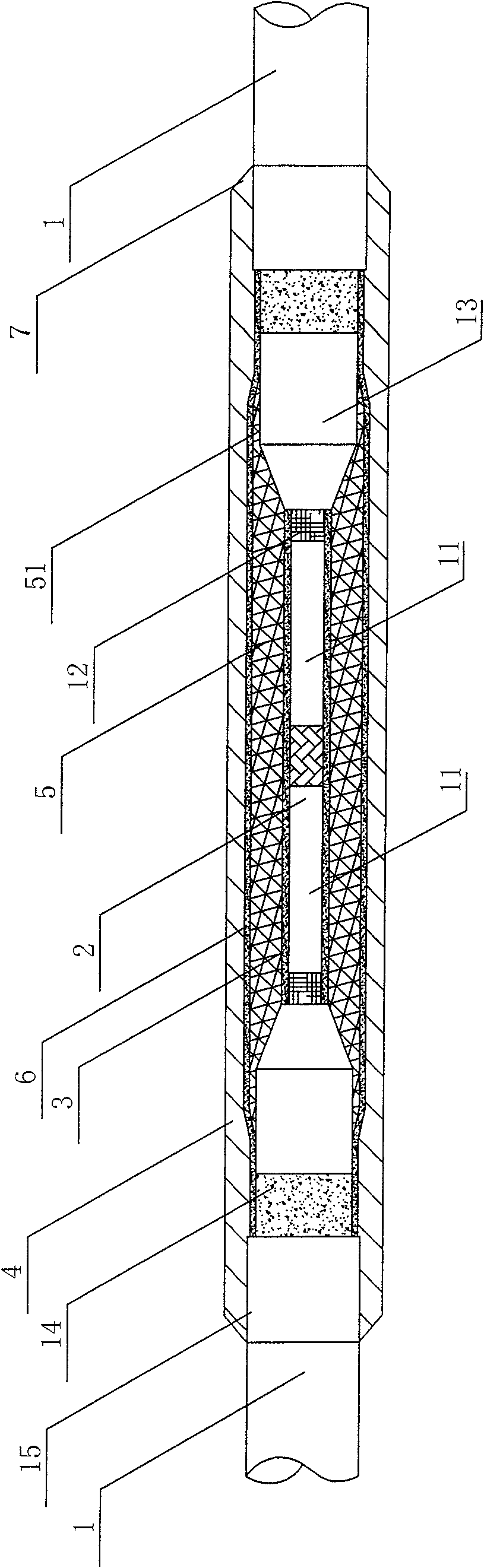

[0018] Embodiment one: if figure 1 As shown, a flexible joint of cross-linked polyethylene cables includes an inner semiconductive layer 3 arranged outside the core connecting portion 2 of two cables 1 and a lead sheath tube 4 arranged on the outermost surface. 2, the cores 11 of the two cables are welded to each other, the inner semiconductive layer 3 is combined with the reserved section 12 of the inner shielding layer of the cable, and the inner semiconductive layer 3 is provided with a polyethylene-filled vulcanized insulating layer 5, which is filled with polyethylene The vulcanized insulating layer 5 is filled and vulcanized by polyethylene material, and the polyethylene filled vulcanized insulating layer 5 is vulcanized and fused with the polyethylene insulating layer 13 of the cable. The transition connection section 51 outside the insulating layer 13, the outer semiconducting layer 6 combined with the reserved section 14 of the outer shielding layer of the cable is ar...

Embodiment 2

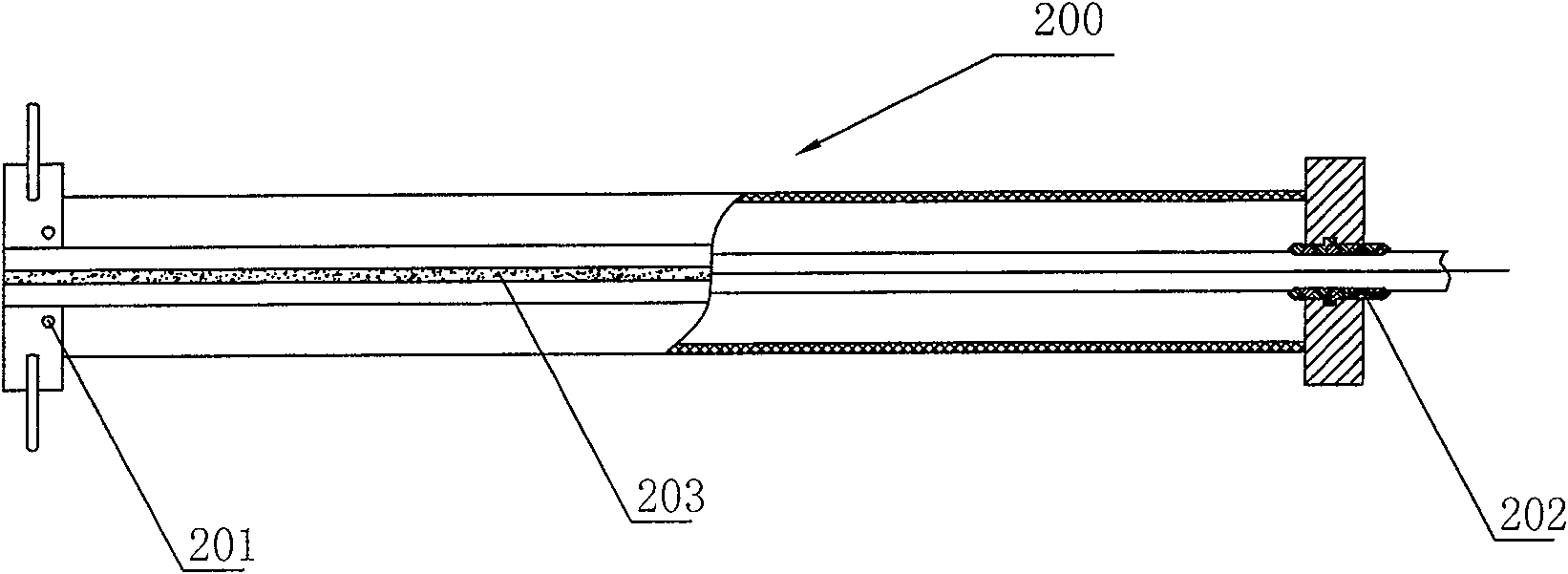

[0019] Embodiment two: the preparation method of the flexible joint of cross-linked polyethylene cable in embodiment one, comprises the following steps: 1. after stripping and cutting the insulation layer 13 of two ends of cable 1, exposed wire core 11, cleans with absolute ethanol, bakes After drying, silver soldering is used to form the core connection part 2. The welding adopts layered welding, and the solder points of each layer are staggered from each other. The mechanical strength of the welding part is required to be no less than 170N / mm 2;② Cut the cross-linked insulating layer 13 on both sides of the joint into a conical shape. When the end of the cone is gradually approaching the inner shielding layer, use a glass sheet to scrape it. Be careful not to scratch the inner shielding as much as possible. When the inner semiconducting layer is exposed Finally, keep the inner shielding layer at the end of the cone for about 15 mm, set the reserved section 12 of the inner shi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com