Bidirectional constant flux gear pump

A constant flow, gear pump technology, used in pumps, pump control, rotary piston pumps, etc., to solve problems such as inability to provide time, high manufacturing costs for radial piston pumps, and operational limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

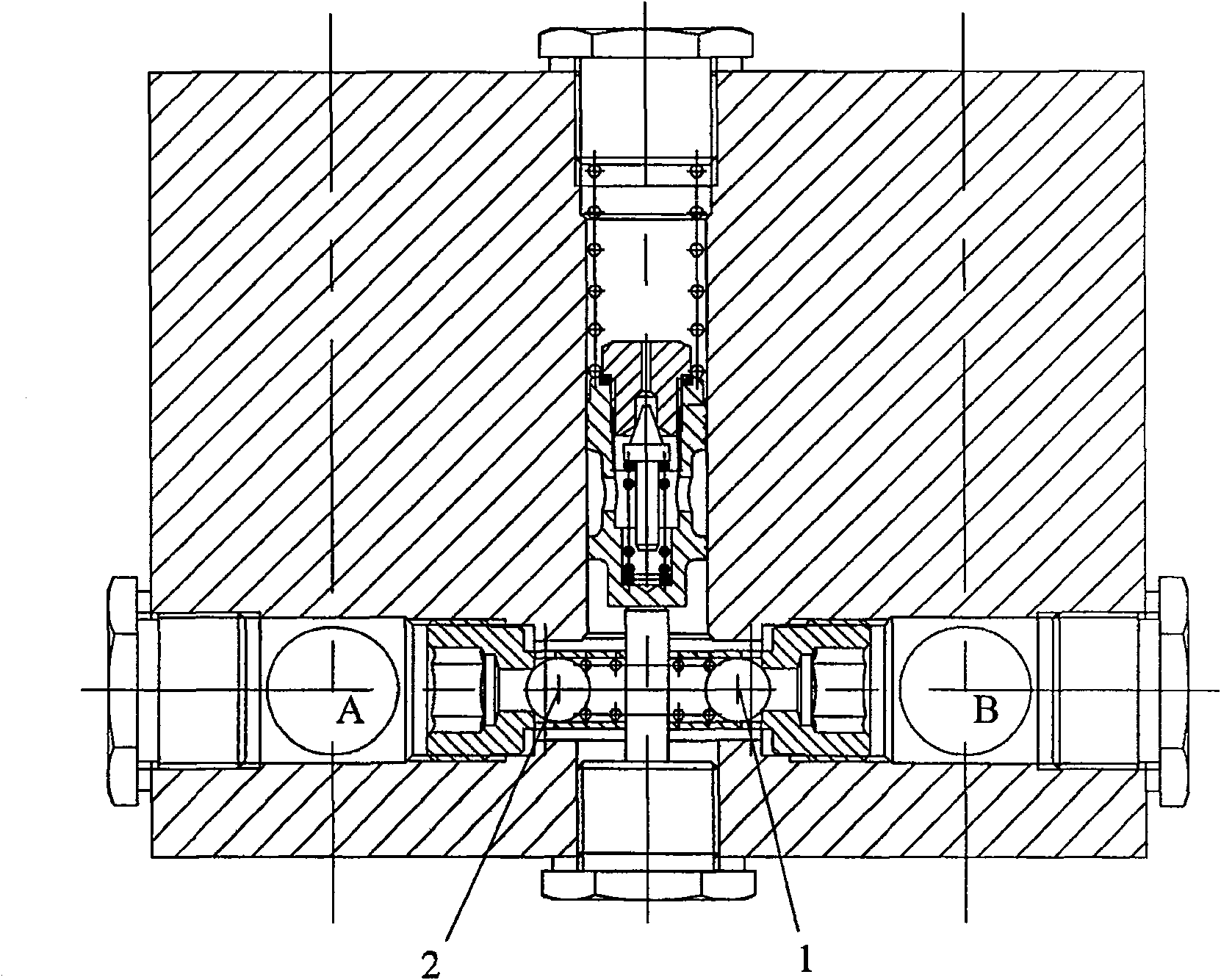

[0023] The present invention is described in further detail below in conjunction with accompanying drawing:

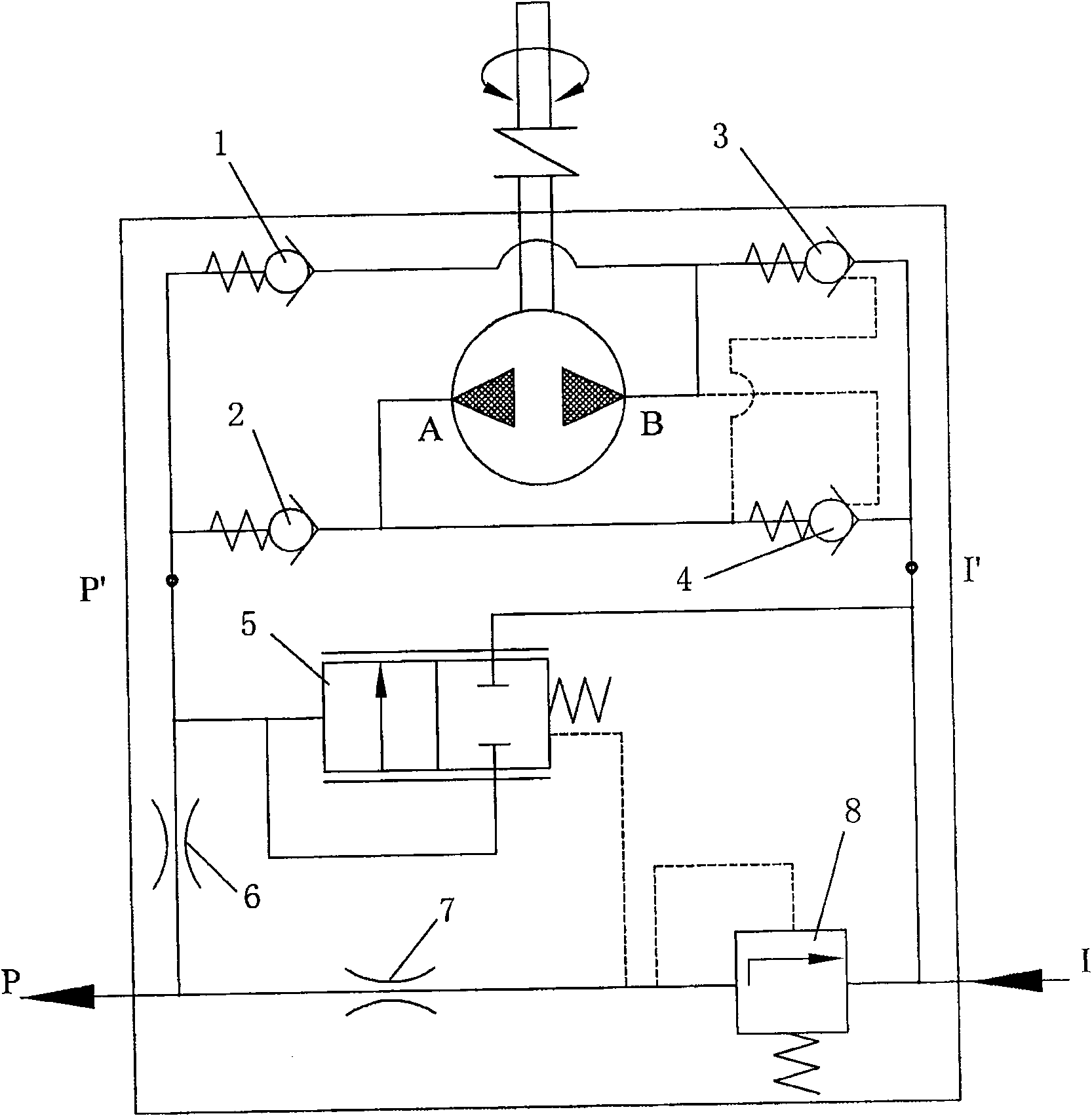

[0024] Such as figure 1 As shown, it is a working principle diagram of the bidirectional constant flow control device of the present invention. When the gear pump rotates in the forward direction, port A absorbs oil and port B discharges oil. Port A absorbs oil to generate negative pressure, and under the action of atmospheric pressure, the second hydraulic control check valve 4 is opened, while the second check valve 2 is closed, so that the gear pump can absorb oil from the oil pump inlet I'; B port discharges oil, the first The hydraulic control check valve 3 is closed, and the oil can only be output to the outlet point P' of the oil pump through the first check valve 1; when the oil discharged from the B port passes through the first check valve 1, a small oil pressure must be established, This pressure can control the second hydraulically controlled one-way valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com