Probe type friction force sensor

A technology of friction sensor and detection needle, which is applied in the field of sensors to achieve continuous dynamic measurement, good economy and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

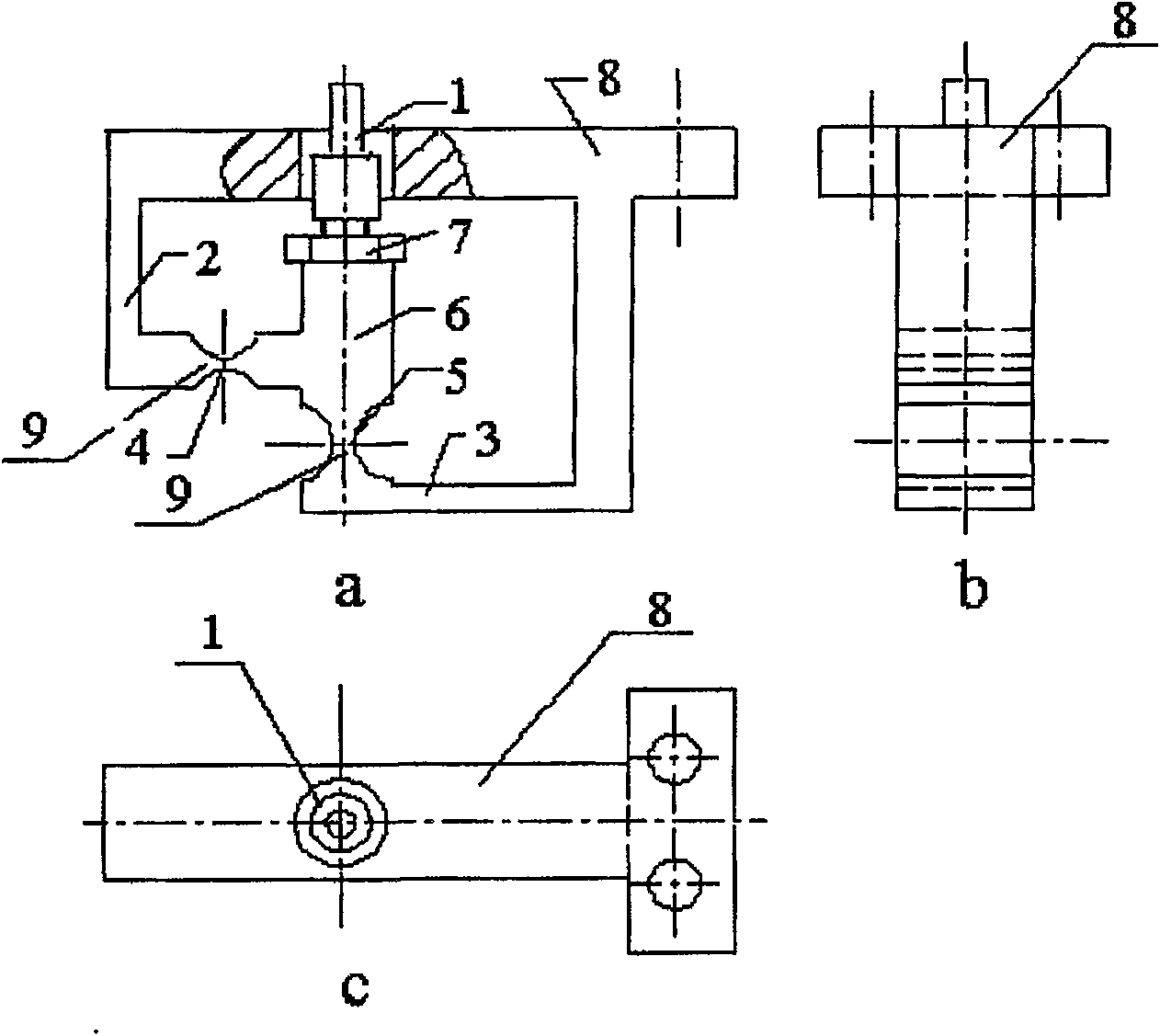

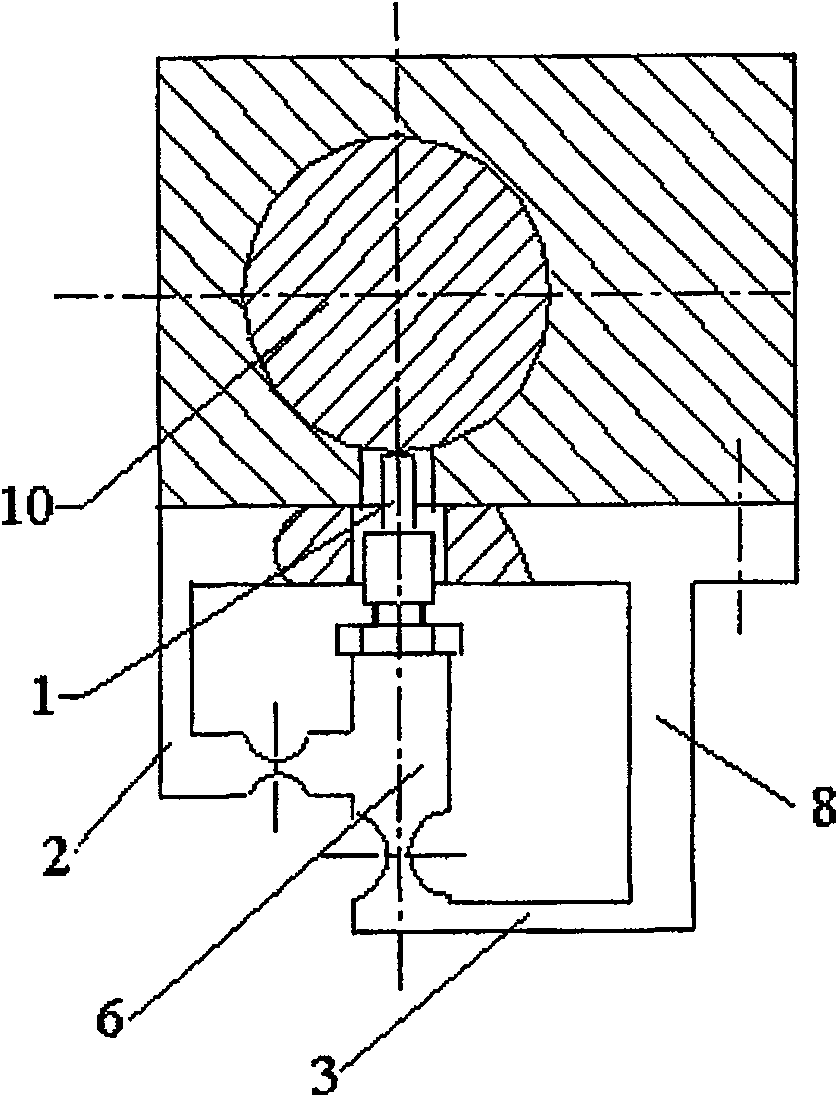

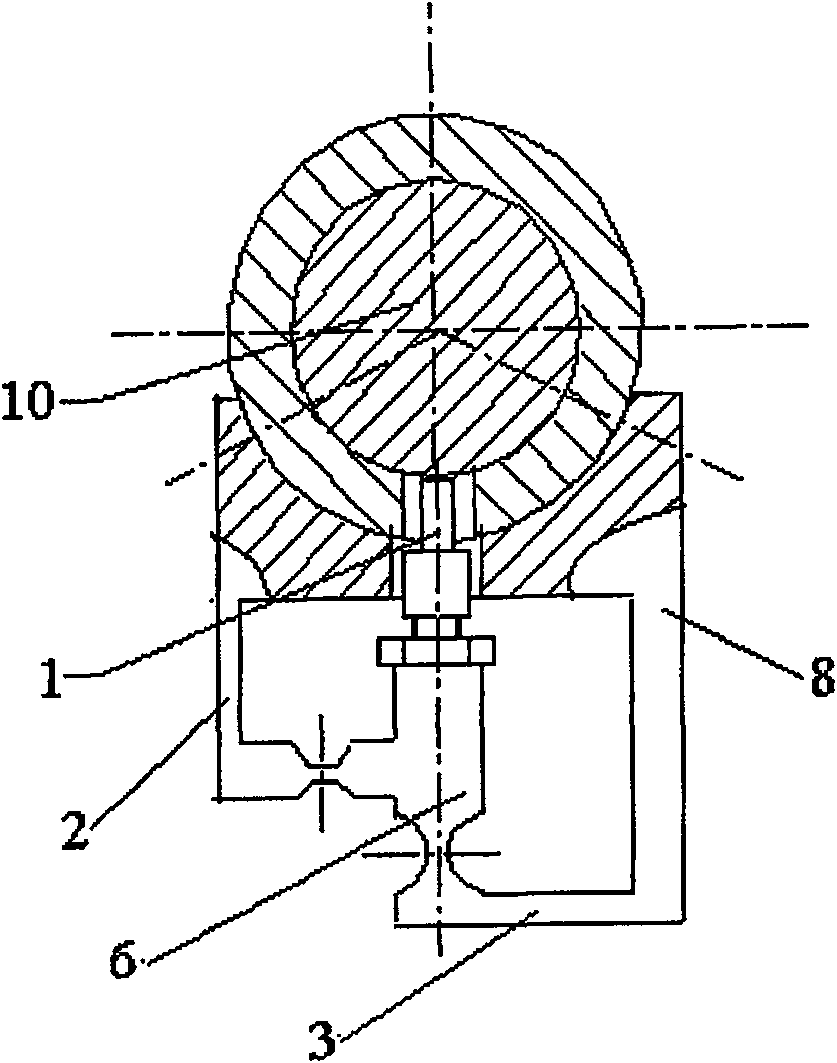

[0011] Such as figure 1 As shown, the sensor of the present invention includes a probe 1 , a fastener 7 , a two-dimensional force sensitive element, and an adhesive resistance strain gauge 9 . The support 8, the tangential force elastic body 2, the positive pressure elastic body 3, and the rigid block 6 form a two-dimensional force sensitive element, and its connection relationship is: the tangential force elastic body 2 is parallel to the rigid block 6, and the first The elastic hinge 4 is connected, the positive pressure elastic body 3 is perpendicular to the rigid block 6, and the two are connected by the second elastic hinge 5, and the tangential force elastic body 2 and the positive pressure elastic body 3 are integrated with the support 8. The two-dimensional force sensitive element is an integrally processed non-combined element. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com