High angle drill at blast furnace casting port

A blast furnace tapping and high-angle technology, which is applied to blast furnaces, blast furnace details, blast furnace parts, etc., can solve the problems of high consumption of drill bits and drill pipes, high labor intensity of workers, and easy falling off of blades, etc., so as to reduce labor intensity, The effect of short opening time and not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

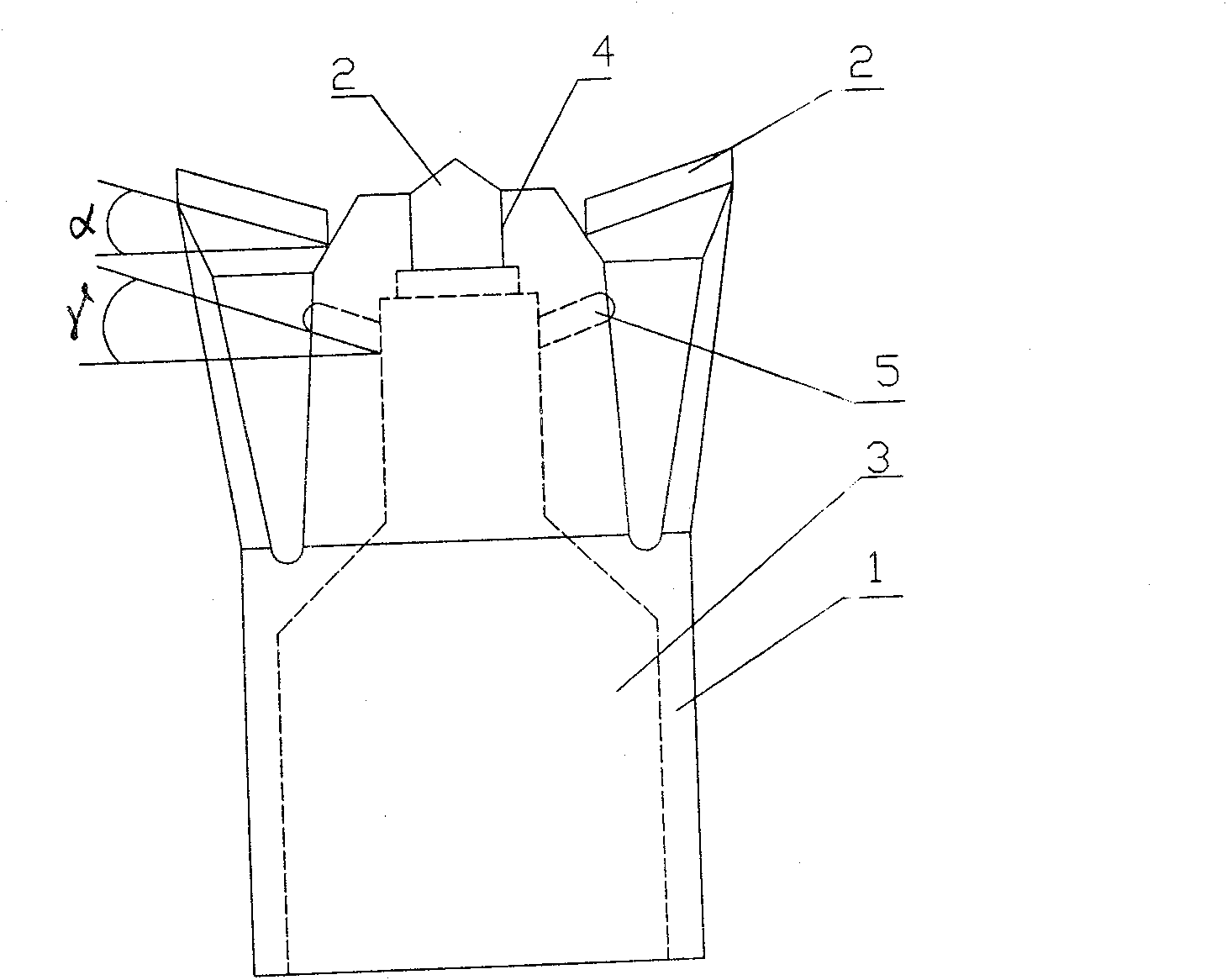

[0019] Further illustrate the present invention below in conjunction with accompanying drawing.

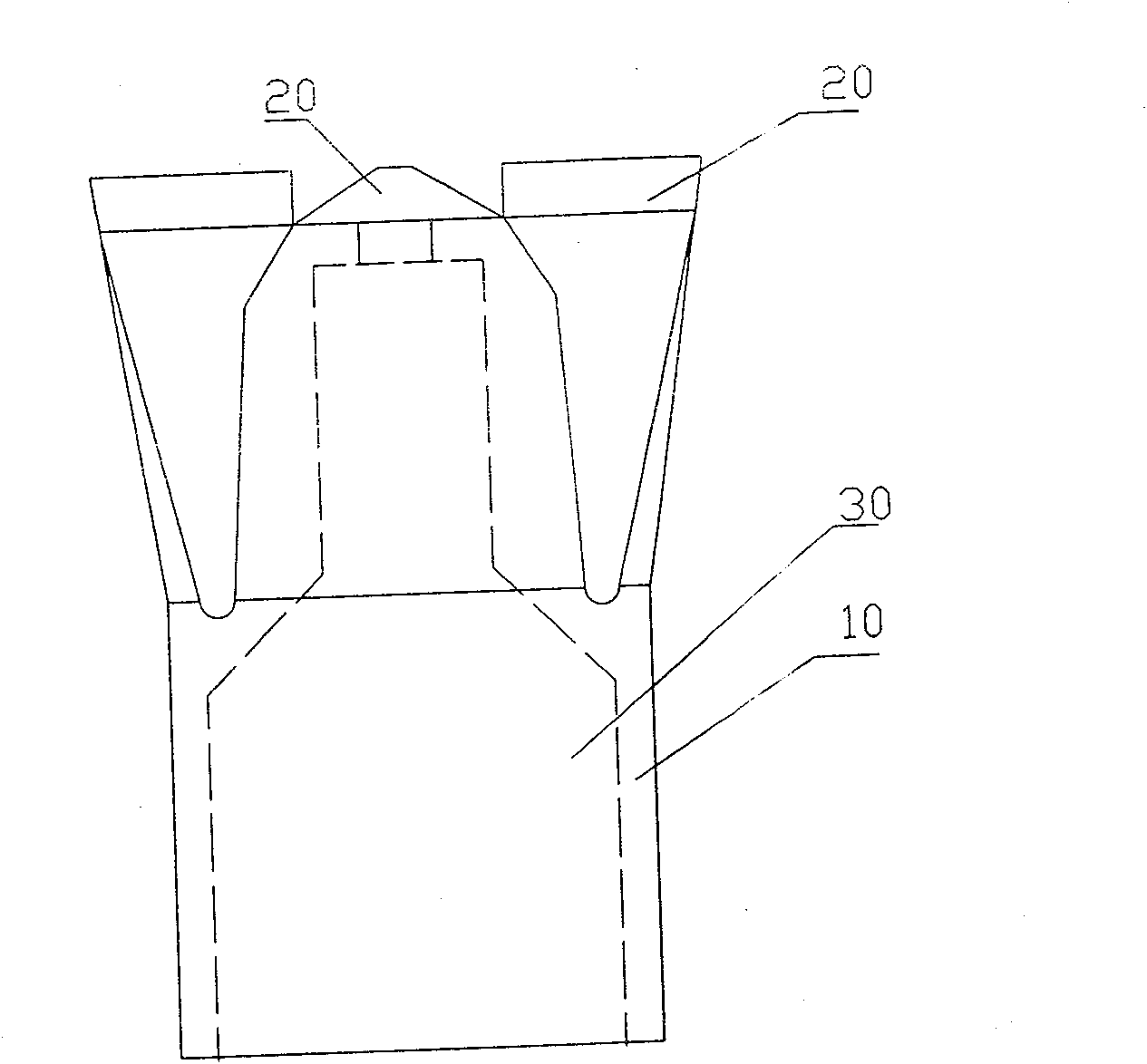

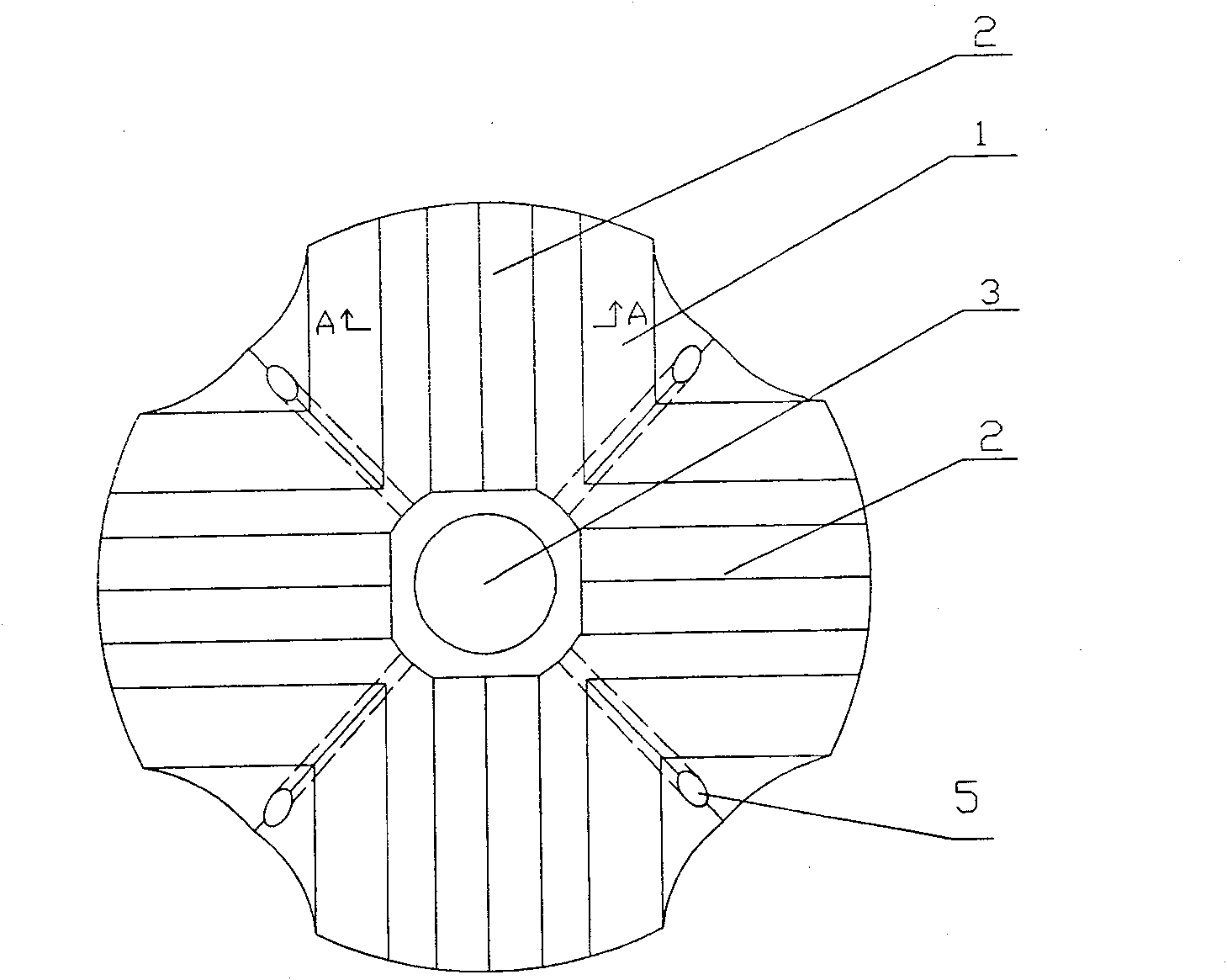

[0020] like Figure 2~3 As shown, a high-angle drill bit for a blast furnace taphole is composed of a base 1, a blade 2, a main air hole 3, a knife groove 4 and a side air hole 5.

[0021] The center of the base 1 is provided with a main air hole 3, and the upper end of the base 1 is evenly made into four wings, and the upper top of the wing is inclined to the main air hole 3 in the center of the base 1, that is, the upper top surface of the wing is in line with the base. The horizontal axis forms an angle α, and α is 7°; a sipe 4 is formed in the center of each wing, and the width of the sipe 4 is 8 mm; as Figure 4 As shown, the blade 2 is welded in the sipe 4, the body of the blade 2 coincides with the sipe 4, the edge is higher than the sipe 4, and the blade angle between the two hypotenuses of the blade is β, and β is 110 °; side vents 5 are provided on the side wall of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com