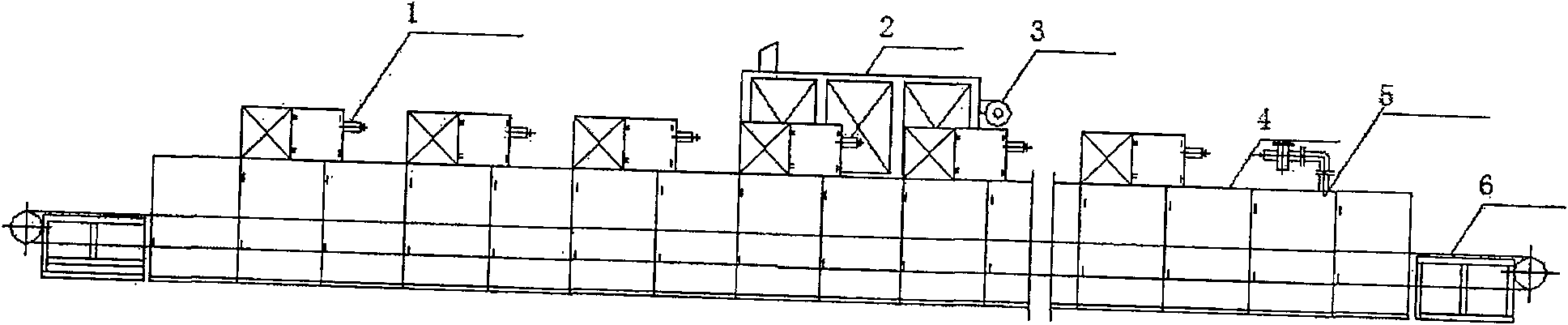

Paper pulp molding drying line based on variable-frequency control technique and preparing process thereof

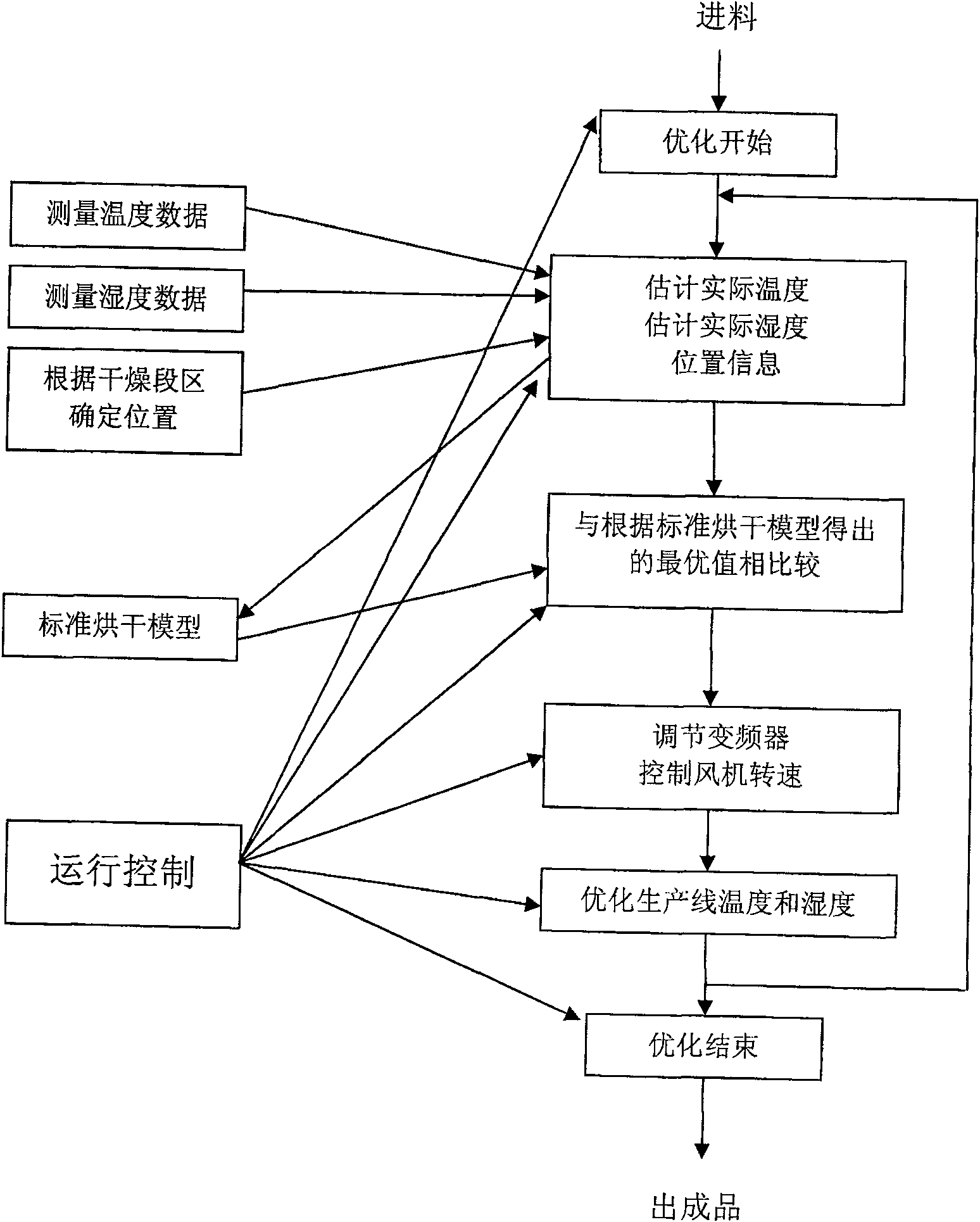

A technology of pulp molding and frequency conversion speed regulation, applied in drying, dryer, drying gas arrangement and other directions, can solve the problems of large energy waste, high scrap rate, short drying time, etc., to reduce energy consumption and material consumption , the effect of saving power loss and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

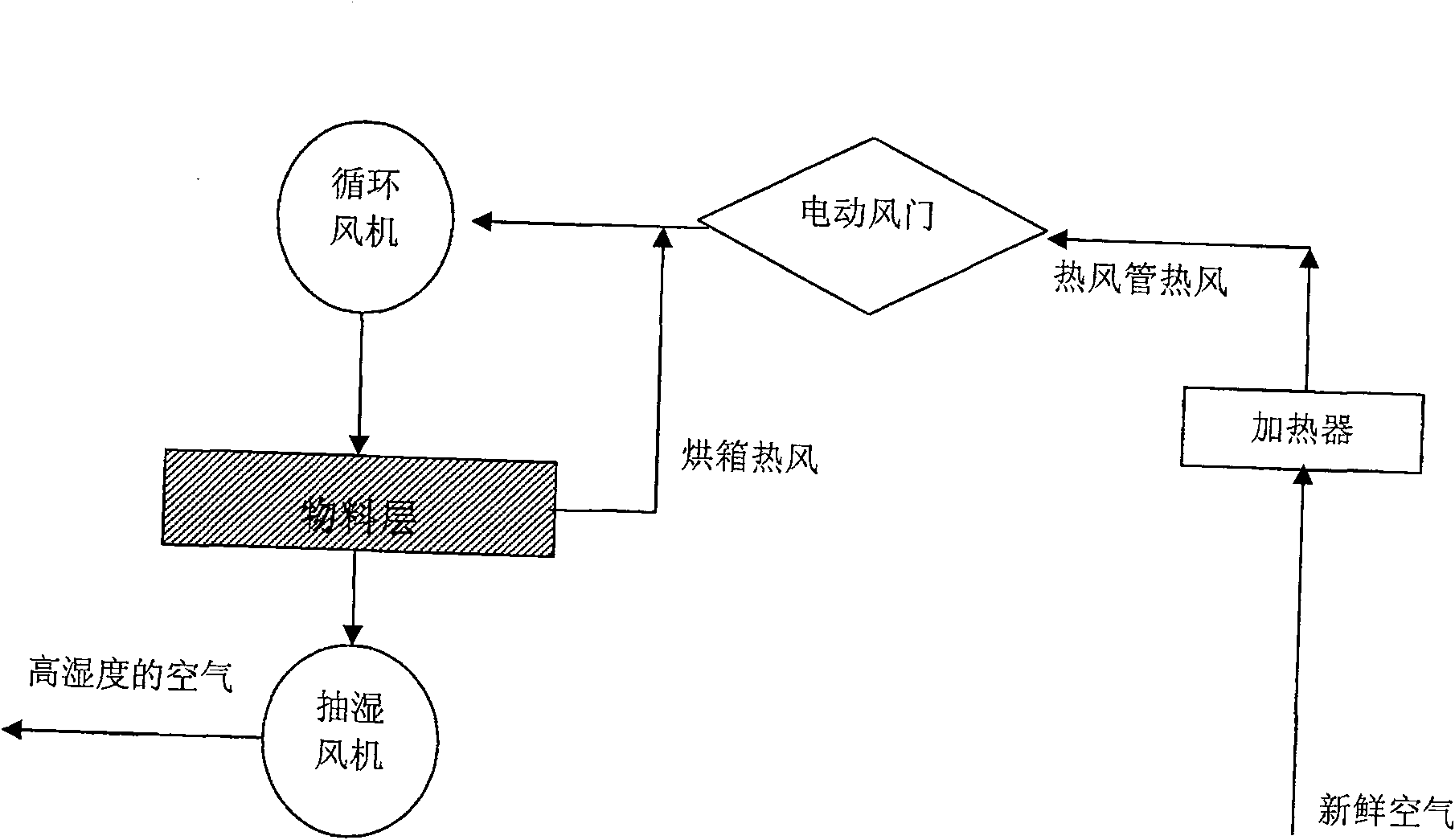

[0033] Pulp molded products contain relatively high moisture (about 70%) after molding, which needs to be removed through a drying process. The moisture content of the finished product after drying is about 10%-15%. There are three forms of water in wet paper fibers: bound water, adsorbed water and free water, and the purpose of drying pulp molded products is to remove bound water and adsorbed water. Pulp molding products are porous media with moisture, and their drying characteristics are relatively complicated. The overall drying process can be divided into three stages: preheating drying, constant speed drying, and reduced speed drying. Usually the duration of the preheating drying stage is relatively short and can be ignored. In the constant-speed drying stage, the wet paper base absorbs heat from the drying medium (hot air), causing the internal moisture to diffuse outward under the pressure gradient, while the surface moisture evaporates into water vapor, which is taken ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com